Oxygen-increasing intermittent gasification method and technique for fixed bed coal gas producer

A technology of coal gasifier and fixed bed, which is applied in the direction of fixed bed gasification, etc. It can solve the problems of low blowing efficiency, exhaust gas emission, and large heat loss, and achieve the effects of good gas quality, reduced exhaust gas emission, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The oxygen-increasing intermittent gasification method of the fixed-bed gasifier of the present invention comprises intermittently passing into the fixed-bed gasifier the oxygen-increased air for blowing off, raising the temperature, and recovering nitrogen, and the oxygen-increased air has an oxygen concentration of 22 %-53%. Within this range of oxygen content, we can use any oxygen-enriched air with an oxygen concentration value according to the site conditions.

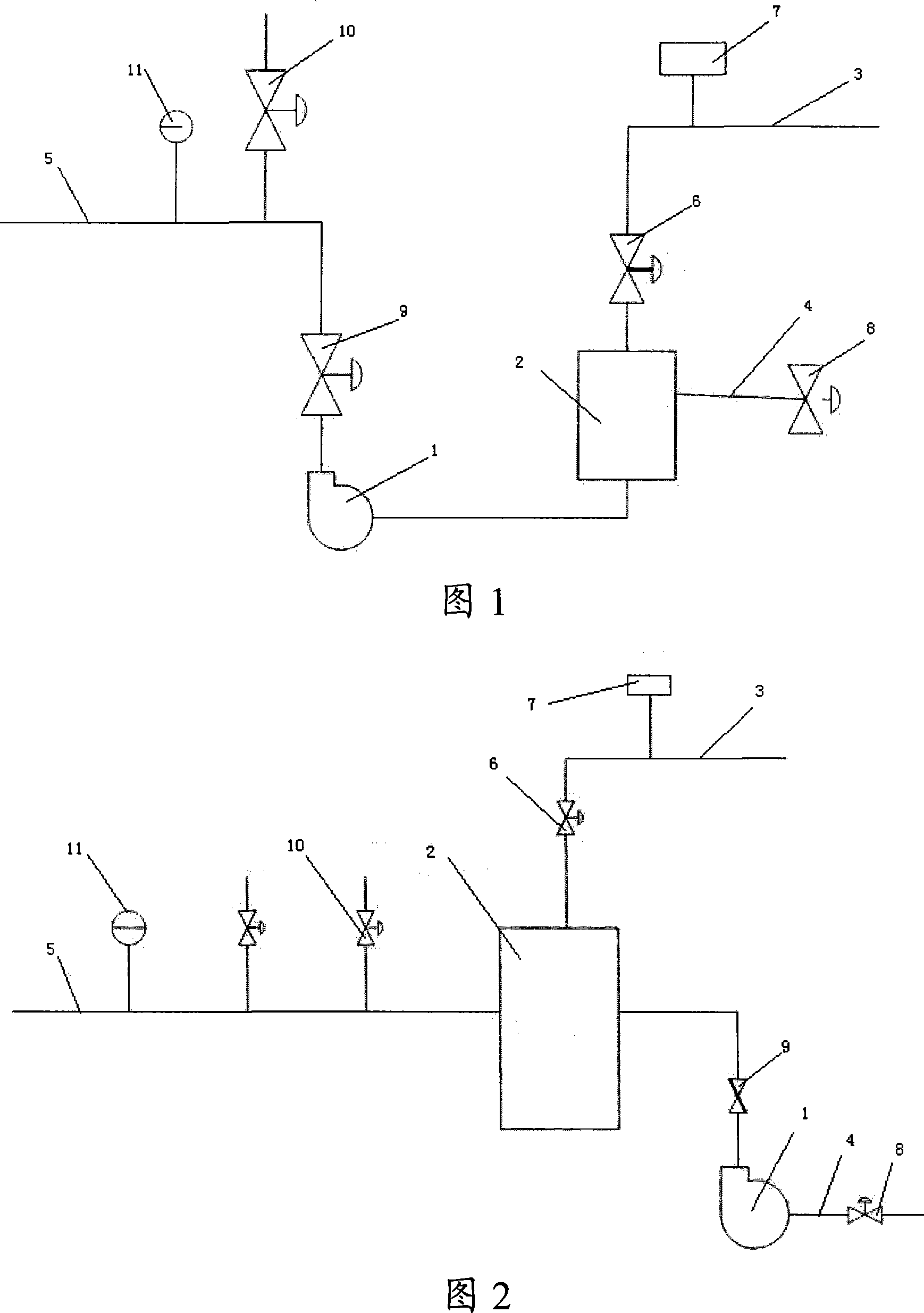

[0016] Produce coal gas with the inventive method, can use the equipment shown in Fig. 1 or Fig. 2. The equipment still includes blower 1, air inlet pipe 4, air valve 8, air pressure regulating valve 9, safety valve 10, also includes oxygen inlet pipe 3, oxygen valve 6, oxygen flow meter 7, and is used to mix oxygen and air. Mixing cavity 2, oxygen analysis instrument 11, oxygen-increasing air main pipe 5. Both the oxygen input pipe 3 and the air input pipe 4 are connected to the mixing chamber 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com