Method for processing three-dimensional metal bead

A processing method, water drop technology, applied in metal material coating process, device for coating liquid on the surface, plating of superimposed layer, etc., to achieve the effect of expanding market share and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

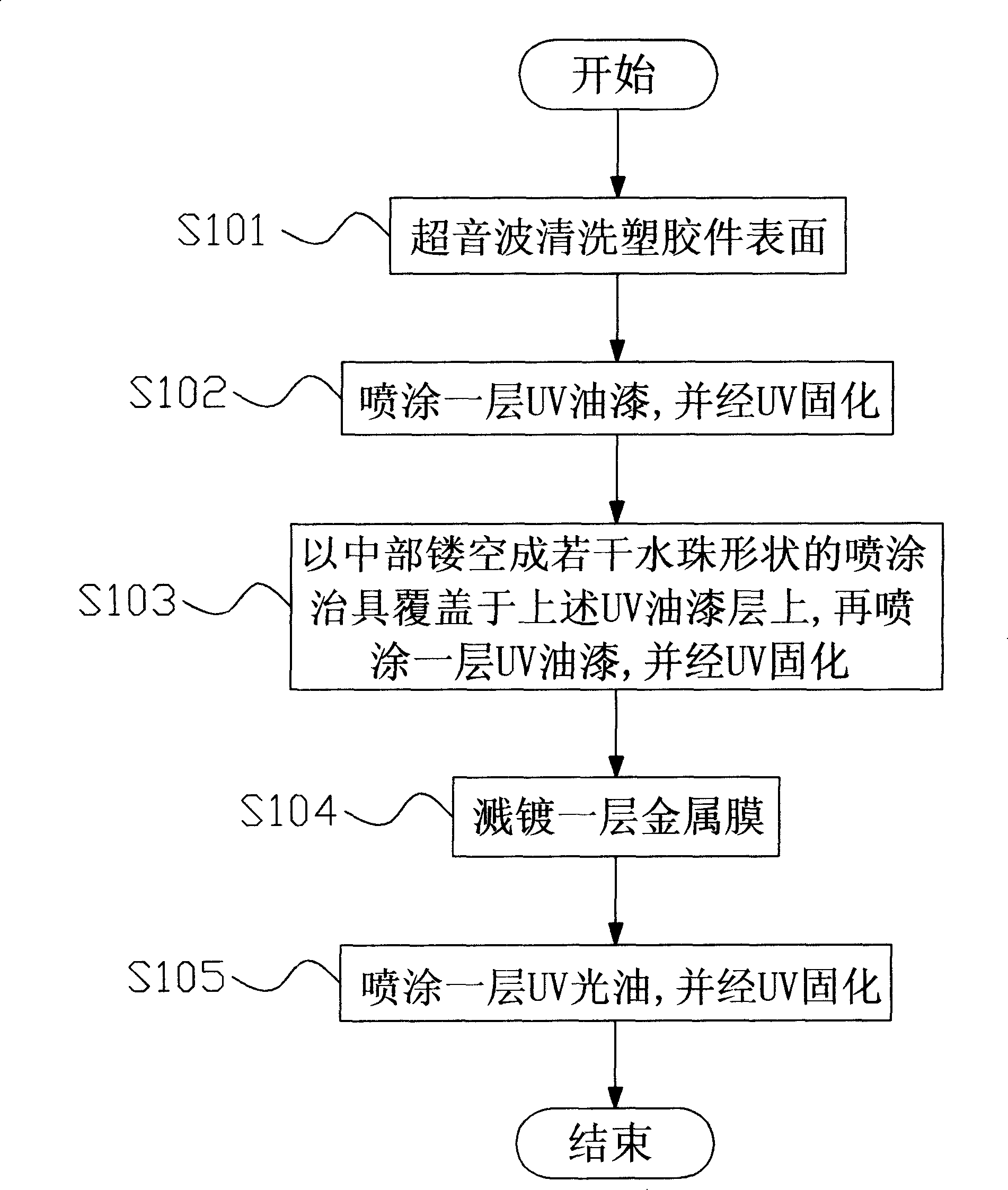

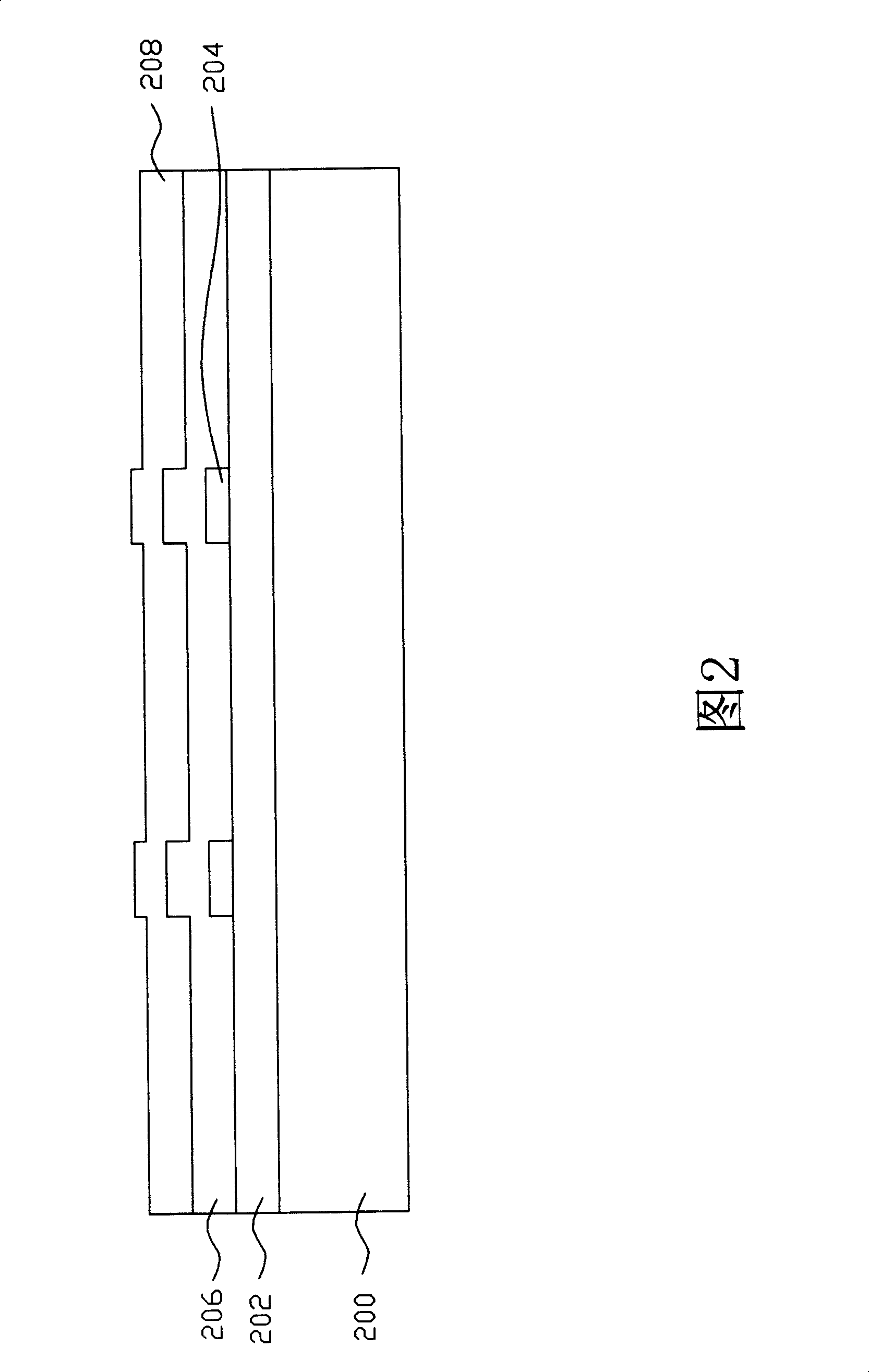

[0015] Please also refer to figure 1 and Figure 2, where figure 1 It is a flowchart of the processing method of the present invention, and FIG. 2 is a schematic cross-sectional view of forming three-dimensional metal drops on a plastic part by using the processing method of the present invention. Its details are as follows:

[0016] Step S101: cleaning the surface of the plastic part 200 with ultrasonic waves.

[0017] Step S102: spraying (spray) an ultraviolet curable paint layer (ie, the first UV paint layer 202), the thickness of the first UV paint layer 202 is 20-25 μm, and then cured by irradiation of an ultraviolet light source (ie, UV curing).

[0018] Step S103: Spray a second UV paint layer 204 on the part where the texture of water drops is to be formed. Preferably, firstly, cover the above-mentioned first UV paint layer 202 with a spraying jig, and the middle part of the spraying jig is hollowed out to form several water droplets. bead shape, and then spray a sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com