Pipeline damage rehabilitation method

A damage repair and pipeline technology, which is applied in the field of improvement of existing pipeline repair methods, can solve problems such as unstable repair quality, inability to continue mass production, and low repair efficiency, and achieve the effect of improving flexibility and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

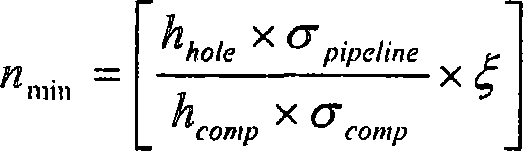

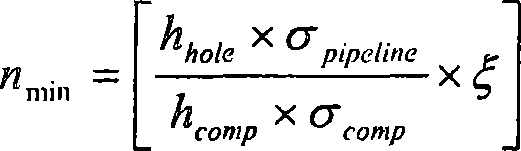

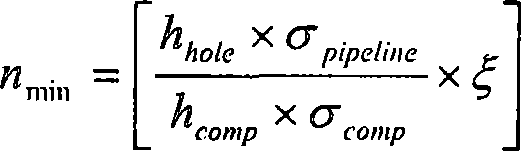

[0051] 1. The working pressure of an oil pipeline is 3.0MPa, the working temperature is 50°C, the diameter of the pipeline is 800mm, and the material is cast iron. It is found that there are corrosion pits in a certain area with a maximum diameter of Φ60mm and a maximum depth of 2.5mm, and there are many corrosion spots around the corrosion pits. In-line repair using room temperature curing carbon fiber plain weave reinforced epoxy resin prepreg. The specific repair steps are: 1) First, clean the surface of the damaged area of the pipeline, use acetone to wipe the corrosion damaged area, and use sandpaper to polish some of the more severely corroded areas, but pay attention not to cause major physical damage to the pipeline body; 2) Clean the And the pipeline after the organic solvent is fully volatilized is wrapped with prepreg (resin content is 35%), and a layer of room temperature curing epoxy resin is coated before the prepreg is wrapped. The insurance factor ξ is taken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com