A monolayer bipolar plate fuel battery with functions of gas humidification, film hydration, dewatering and cooling

A fuel cell and membrane hydration technology, which is applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of difficult control of gas humidity and difficult discharge of water, and achieve saving plate materials and high hydration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

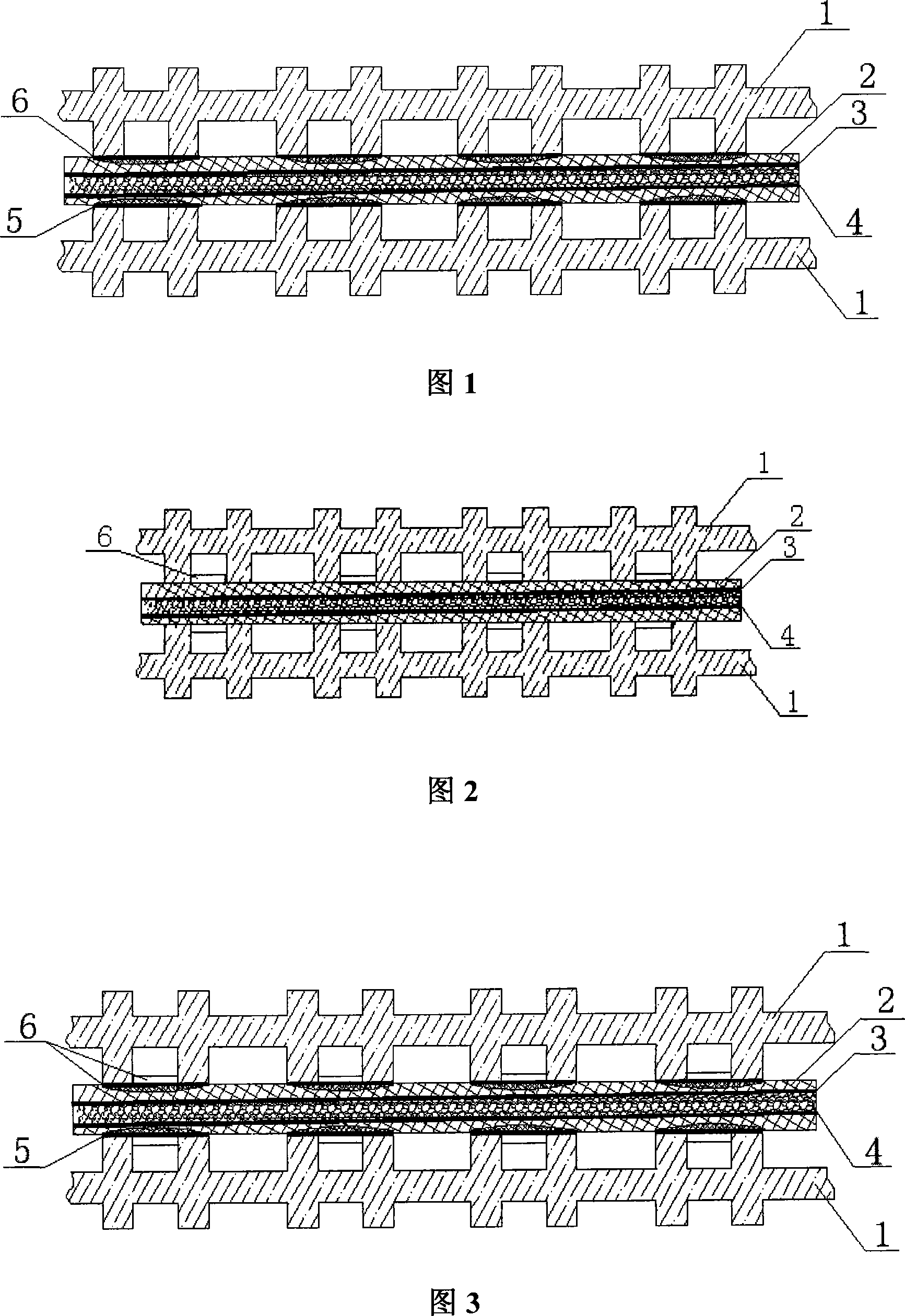

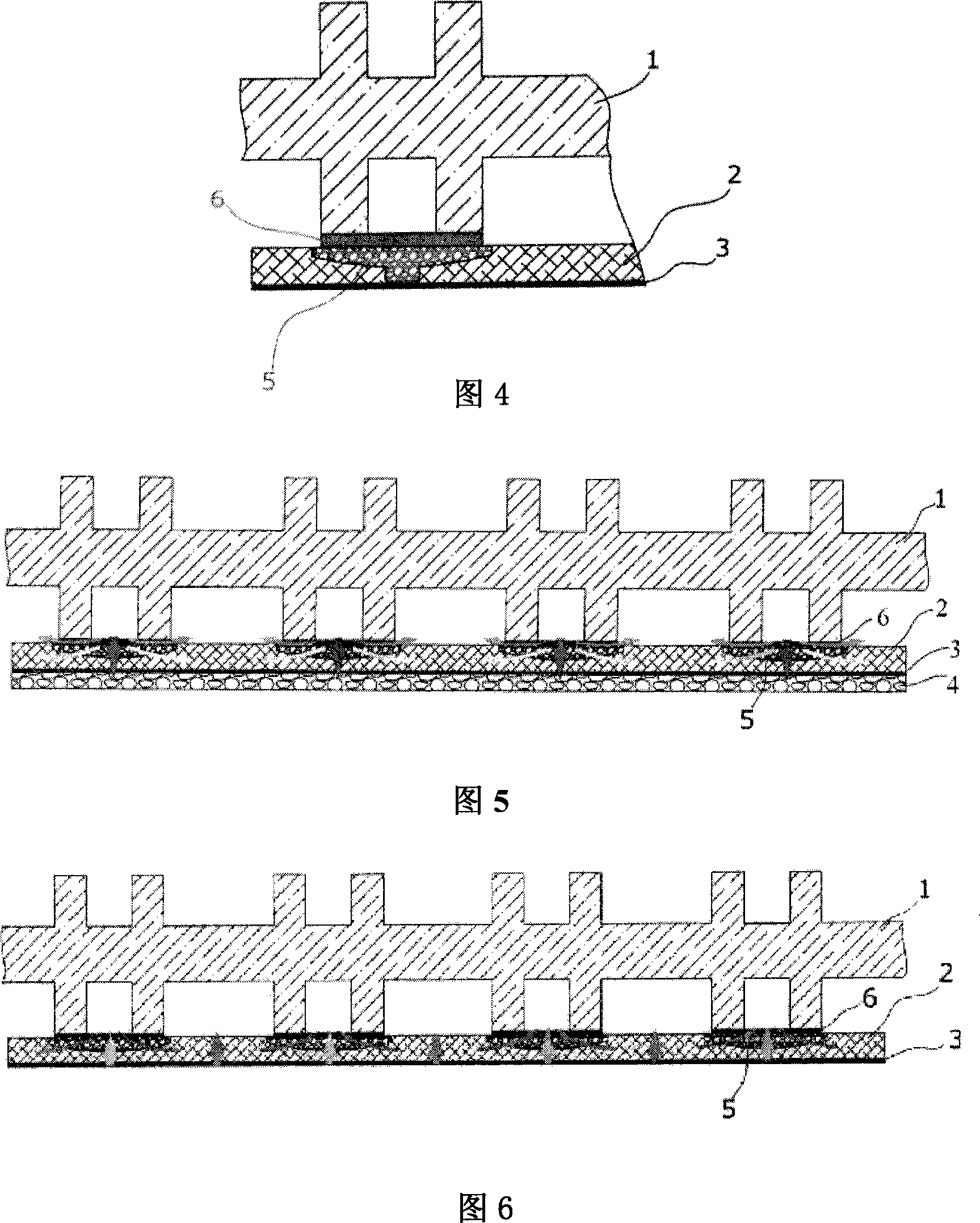

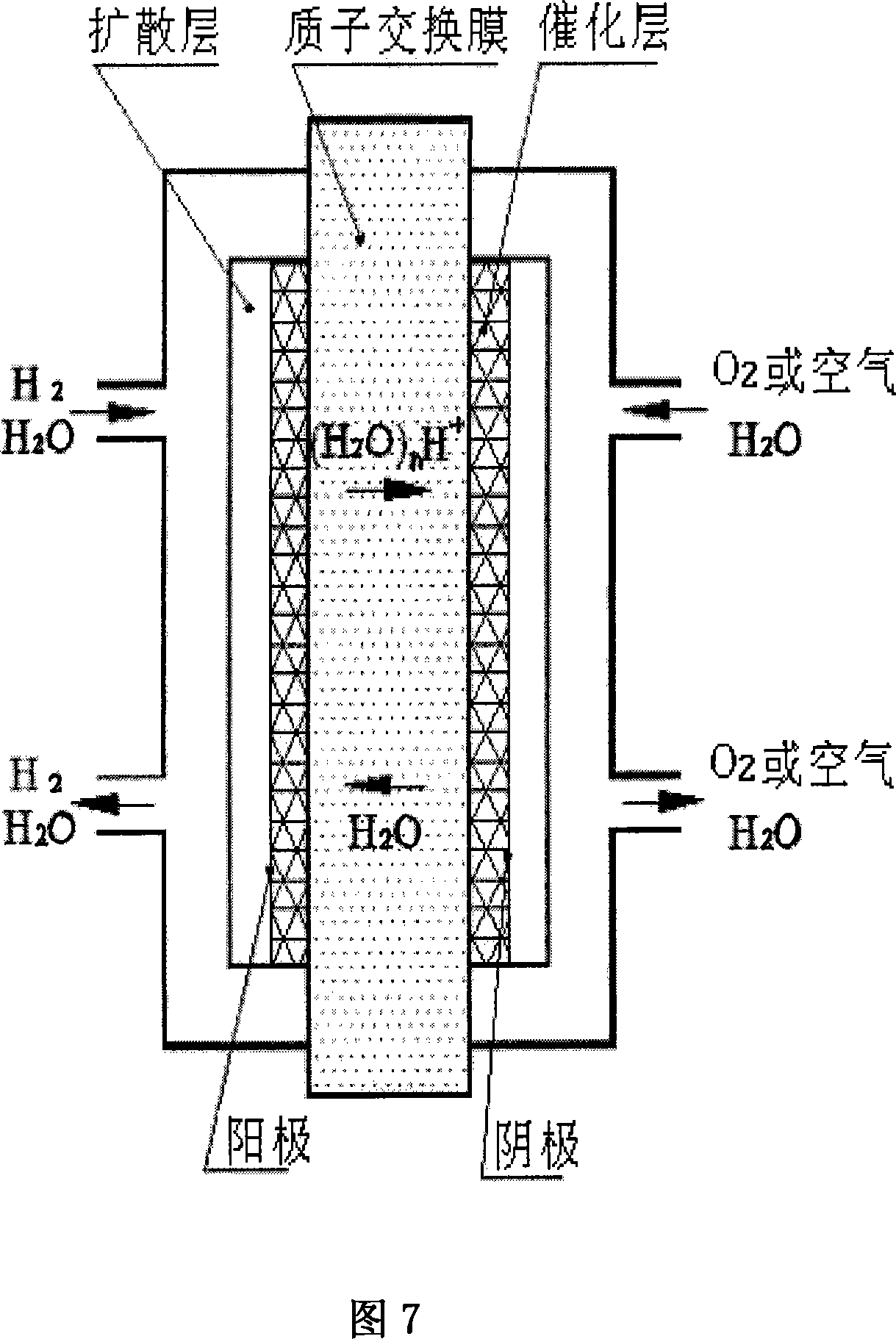

[0029] Embodiment 1: as shown in Figure 1, the present invention comprises proton exchange membrane 4, and the both sides of proton exchange membrane 4 are compounded with catalyst layer 3, and catalyst layer 3 is compounded with the gas diffusion layer 2 that handles through moisturizing material, gas diffusion layer The two sides of 2 are respectively equipped with single-layer board 1 as cathode and anode, one side of single-layer board 1 as cathode is provided with air channel 7 and cooling water flow channel 8, and one side of single-layer board 1 as anode is provided with hydrogen gas The flow channel 9 and the cooling water flow channel 10, the cooling water flow channel 8 and 10 communicate with the gas diffusion layer 2 through holes, and the water-conducting layer 6 treated with the water transmission material is arranged between the cooling water flow channel and the contact surface of the gas diffusion layer, and the air Air and hydrogen are fed into the flow channe...

Embodiment 2

[0030] Embodiment 2: as shown in Figure 2, the present invention comprises proton exchange membrane 4, and the both sides of proton exchange membrane 4 are compounded with catalyst layer 3, and catalyst layer 3 is compounded with the gas diffusion layer 2 that handles through moisturizing material, gas diffusion layer 2 The two sides of the single-layer board 1 are respectively equipped with a cathode and an anode, and one side of the single-layer board as the cathode is provided with an air flow channel 7 and a cooling water flow channel 8, and the side of the anode single-layer board is provided with a hydrogen flow channel 9 at the corresponding position. And the cooling water flow channel 10, the cooling water flow channel 10 is connected with the gas diffusion layer through the porous, the water conducting layer 6 treated with the water transmission material is arranged in the cooling water flow channel, the air flow channel 7 and the hydrogen flow channel 9 are respectivel...

Embodiment 3

[0031] Embodiment 3: as shown in Figure 3, the present invention comprises proton exchange membrane 4, and the both sides of proton exchange membrane 4 are compounded with catalyst layer 3, and catalyst layer 3 is compounded with the gas diffusion layer 2 that handles through moisturizing material, gas diffusion layer 2 The two sides of the single-layer board 1 are respectively equipped with a cathode and an anode, and one side of the single-layer board as the cathode is provided with an air flow channel 7 and a cooling water flow channel 8, and the side of the anode single-layer board is provided with a hydrogen flow channel 9 at the corresponding position. And the cooling water flow channel 10, the cooling water flow channel communicates with the gas diffusion layer through holes, and the water-conducting layer 6 treated with the water transmission material is arranged in the cooling water flow channel and between the cooling water flow channel and the contact surface of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com