An electrostatic protection structure of high voltage drive integrated circuit

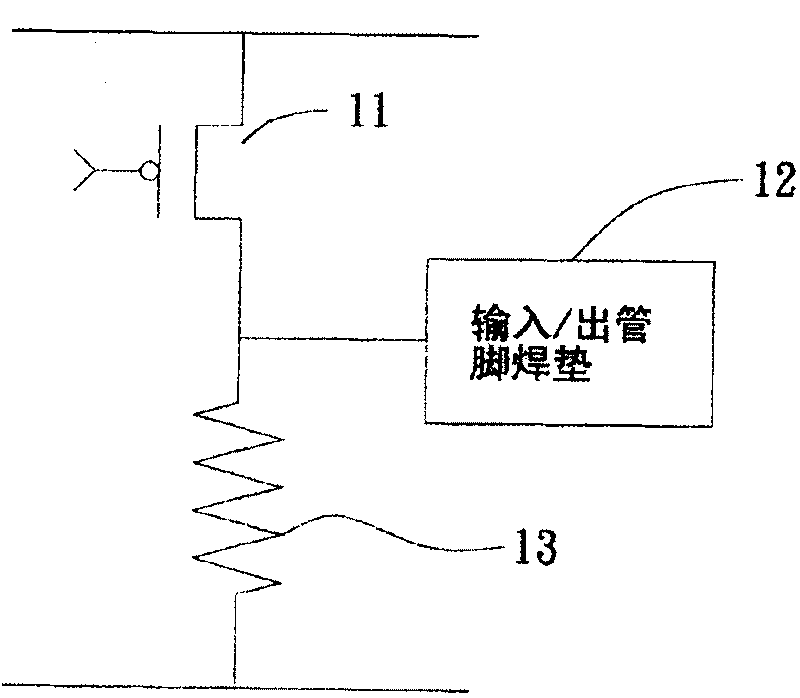

An integrated circuit, high-voltage drive technology, applied in the direction of circuits, circuit devices, emergency protection circuit devices, etc., can solve the problems of inability to effectively protect integrated circuits, flow, and drive the output pins of integrated circuits to burn out, so as to improve electrostatic discharge Protective ability, the effect of preventing electrostatic discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The detailed structure of the present invention and its connections are now described in conjunction with the following drawings to facilitate a further understanding of the present invention.

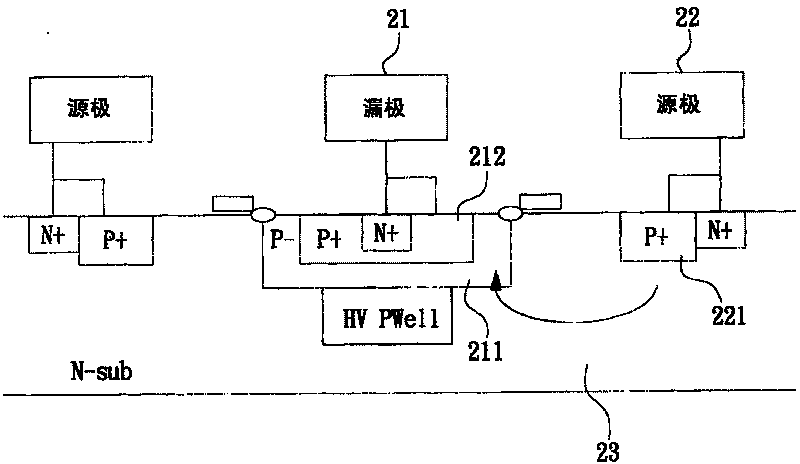

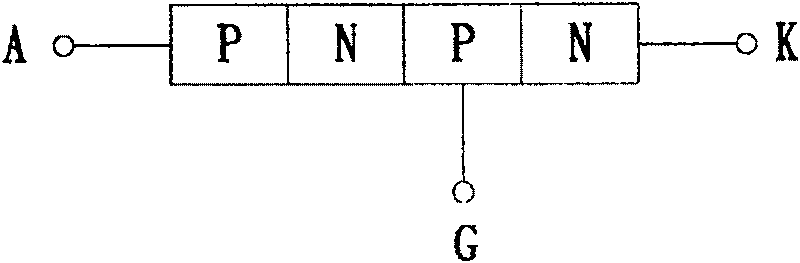

[0078] see Figure 2A , Figure 2A The structural diagram of the silicon-controlled rectifier added to the high-voltage drive integrated circuit of the present invention; wherein, the metal oxide semiconductor field effect transistor includes at least a drain (Drain) 21 and a source (Source) 22, and its output pin (source) Between the pole 22 and the drain 21) a silicon controlled rectifier (Silicon Controlled Rectifier, SCR) is added. Please also see Figure 2B As shown, wherein, the silicon controlled rectifier is an electronic component composed of a PNPN interface, passing through the P+ dielectric 221 of the source (Source) 22 to the N-type substrate 23, and then from the N-type substrate 23 to the drain (Drain) 21 P- dielectric 211 or P+ dielectric 212, and then forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com