Apparatus and method for dehalogenation regeneration of waste and old electric plastics

A technology for dehalogenation and plastics, which is applied in the regeneration of high-halogen-containing waste plastics and waste electronic plastics regeneration devices. It can solve the problems of high energy consumption in the treatment process, high cost of product separation and purification, and poor economic benefits, so as to ensure environmental protection. Friendliness, guaranteed recycling and high quality and high use, and the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

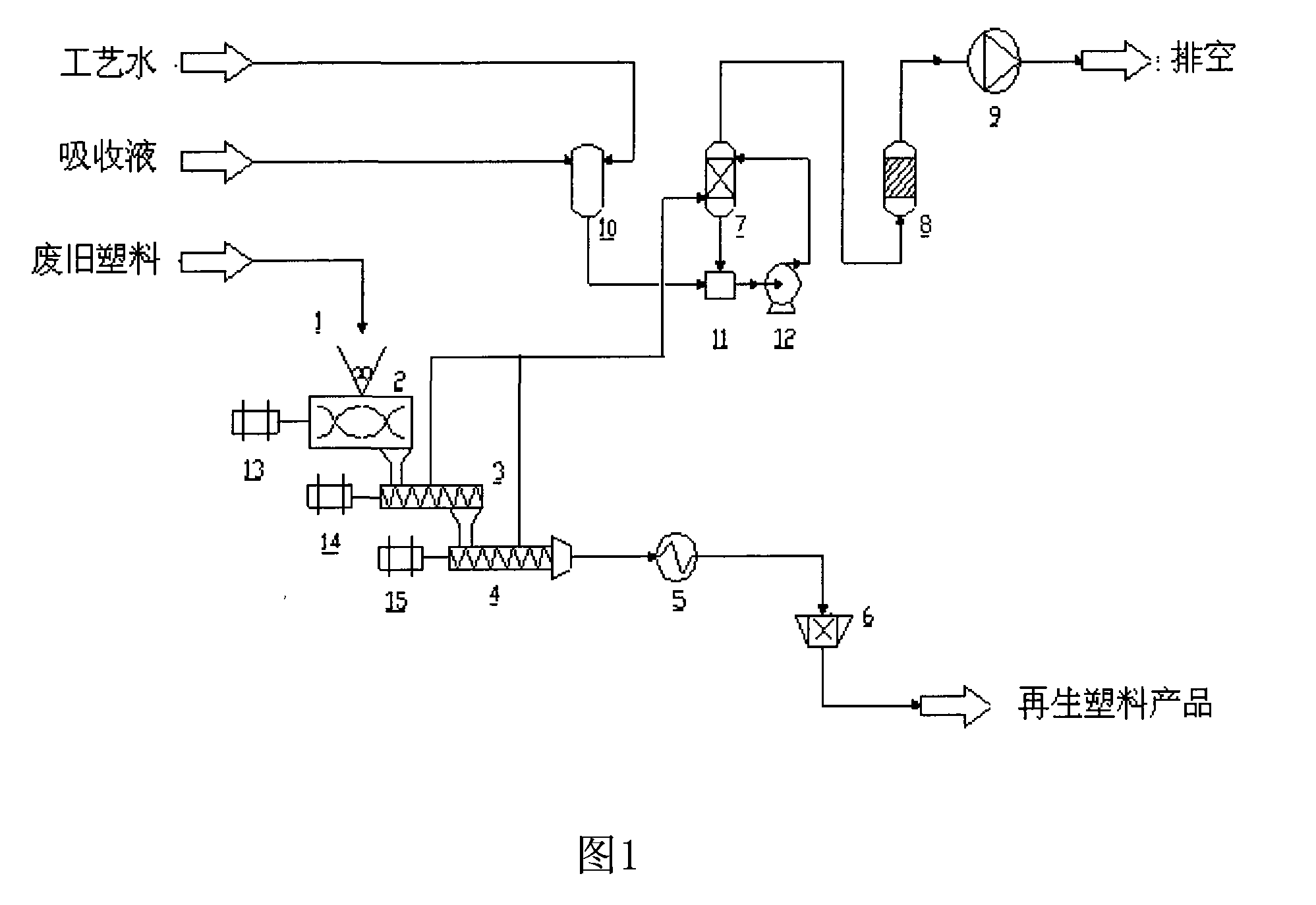

Image

Examples

Embodiment 1

[0029] Embodiment 1: Vacuum dehalogenation-regeneration treatment of TV casing:

[0030] Elemental analysis was carried out after crushing the plastic PS plastic sample of waste TV casing, and the mass percentage content of bromine in the sample was measured to be 5.12%. In addition, it was determined by gas chromatography and mass spectrometry (GC-MS) Heptabromodiphenyl ether (7Br-PBDE), octabromodiphenyl ether (8Br-PBDE), etc. Put 100kg of waste electronic plastic samples of the above waste TV casing plastic PS plastics into the feeder after sorting and crushing; dry at 80°C, remove the moisture in the raw materials and send them to the dehalogenation reactor; at a temperature of 300°C , under the pressure of 60kPa, after 30 minutes of reaction, the brominated flame retardants (BFRs) are transformed into small molecule brominated compounds, which are separated from the waste electronic plastic melt in the form of gas, thereby realizing dehalogenation, and the removal rate of...

Embodiment 2

[0032] Elemental analysis was carried out after crushing the plastic PS plastic sample of waste TV casing, and the mass percentage content of bromine in the sample was measured to be 5.12%. In addition, it was determined by gas chromatography and mass spectrometry (GC-MS) Heptabromodiphenyl ether (7Br-PBDE), octabromodiphenyl ether (8Br-PBDE), etc. Add 100kg of waste electronic plastic samples of the above-mentioned waste TV casing plastic PS plastics to the feeder after sorting and crushing; dry at 100°C, remove the moisture in the raw materials and send them to the dehalogenation reactor; at a temperature of 330°C , under the pressure of 50kPa, after 40 minutes of reaction, the brominated flame retardants (BFRs) are transformed into small molecule brominated compounds, which are separated from the waste electronic plastic melt in the form of gas, thereby realizing dehalogenation, and the removal rate of halogen reaches 96%. The tail gas of this system mainly comes from the d...

Embodiment 3

[0034] Elemental analysis was carried out after crushing the plastic PS plastic sample of waste TV casing, and the mass percentage content of bromine in the sample was measured to be 5.12%. In addition, it was determined by gas chromatography and mass spectrometry (GC-MS) Heptabromodiphenyl ether (7Br-PBDE), octabromodiphenyl ether (8Br-PBDE), etc. Put 100kg of waste electronic plastic samples of the above waste TV casing plastic PS plastics into the feeder after sorting and crushing; dry at 150°C, remove the moisture in the raw materials and send them to the dehalogenation reactor; at a temperature of 350°C , under the pressure of 40kPa, after 50 minutes of reaction, the brominated flame retardants (BFRs) are transformed into small molecule brominated compounds, which are separated from the waste electronic plastic melt in the form of gas, thereby realizing dehalogenation, and the removal rate of halogen reaches 98%. The tail gas of this system mainly comes from the dehalogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com