High-performance ring shaped agglutinate rare earth ultra-magnetostriction material, manufacturing method and device thereof

A giant magnetostrictive and rare earth technology, applied in the direction of device material selection, can solve the problems of complicated operation, high difficulty, and high requirements for preparation equipment, and achieve the effect of simple equipment and process, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) The composition is Tb 0.3 Dy 0.70 Fe 1.95 The raw materials are placed in anhydrous ethanol protection medium, mechanically crushed and powdered, and anhydrous ethanol is extracted with petroleum ether for 2-3 times. Water and ethanol are stored for later use; when using, repeat the above extraction and drying process;

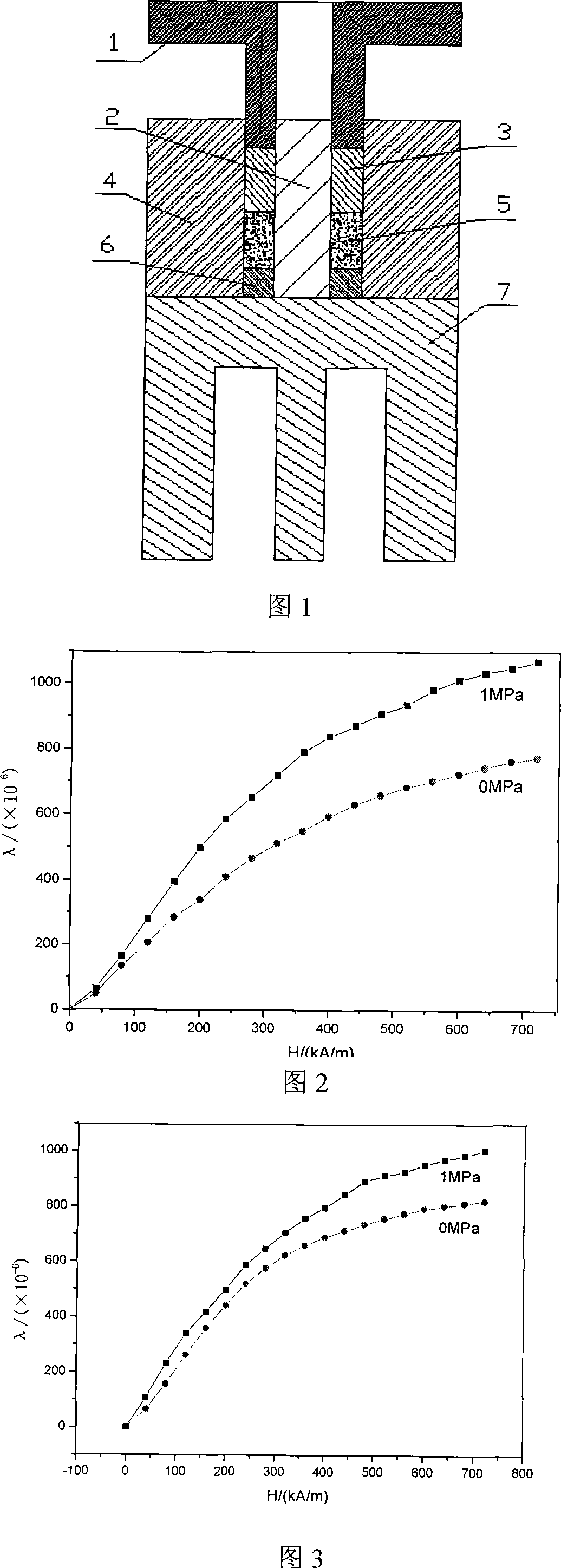

[0034](2) The epoxy resin E-44 which accounts for 5.3% of the total amount of ingredients and the alloy powder of 94% are batched, placed in an acetone solvent to fully stir and mix the mixture, while heating and evaporating the solvent, after cooling, add 0.7% of the total amount of ingredients % of polyethylene polyamine, after fully stirring, is transferred to the ring-shaped cavity mold, and the lower cavity insert 6, the raw material for filling the product 5, and the upper cavity insert 3 are placed in the cavity of the mold from bottom to top, The loading and unloading formwork 1 is plugged into the cavity 4;

[0035] (3) Under the pressu...

Embodiment 2

[0038] As shown in Example 1, the difference is that in the step (2), according to the batching of 1.8% epoxy resin and 98% alloy powder batching of the total batching amount, add 0.2% polyethylene polyamine accounting for the total batching amount, without adding The saturation magnetostriction coefficient is 774×10 when prestressed -6 , after adding 1MPa prestress, the saturation magnetostriction coefficient increases to 1070×10 -6 ;The density of the sample is 7.10g / cm 3 . The relationship curve between the magnetostriction coefficient and the intensity of the external magnetic field of the annular bonded rare earth giant magnetostrictive material prepared in this example is shown in FIG. 3 .

Embodiment 3

[0040] As shown in Example 1, the difference is that in the step (2), according to the batching of 11.5% epoxy resin and 87% alloy powder batching of the total batching amount, add polyethylene polyamine accounting for 1.5% of the total batching amount, without pre-addition The saturation magnetostriction coefficient under stress is 592×10 -6 , after adding 1MPa prestress, the saturation magnetostriction coefficient increases to 855×10 -6 ;The density of the sample is 4.69g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com