Crystalline state alloy spherical particle/amorphous alloy base composite material and manufacturing method thereof

A technology of amorphous alloys and spherical particles, which is applied in the field of design and preparation of amorphous composite materials, can solve the problems of poor plasticity of amorphous alloys, achieve the effect of reducing influence, shortening the preparation process and cost, and having good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

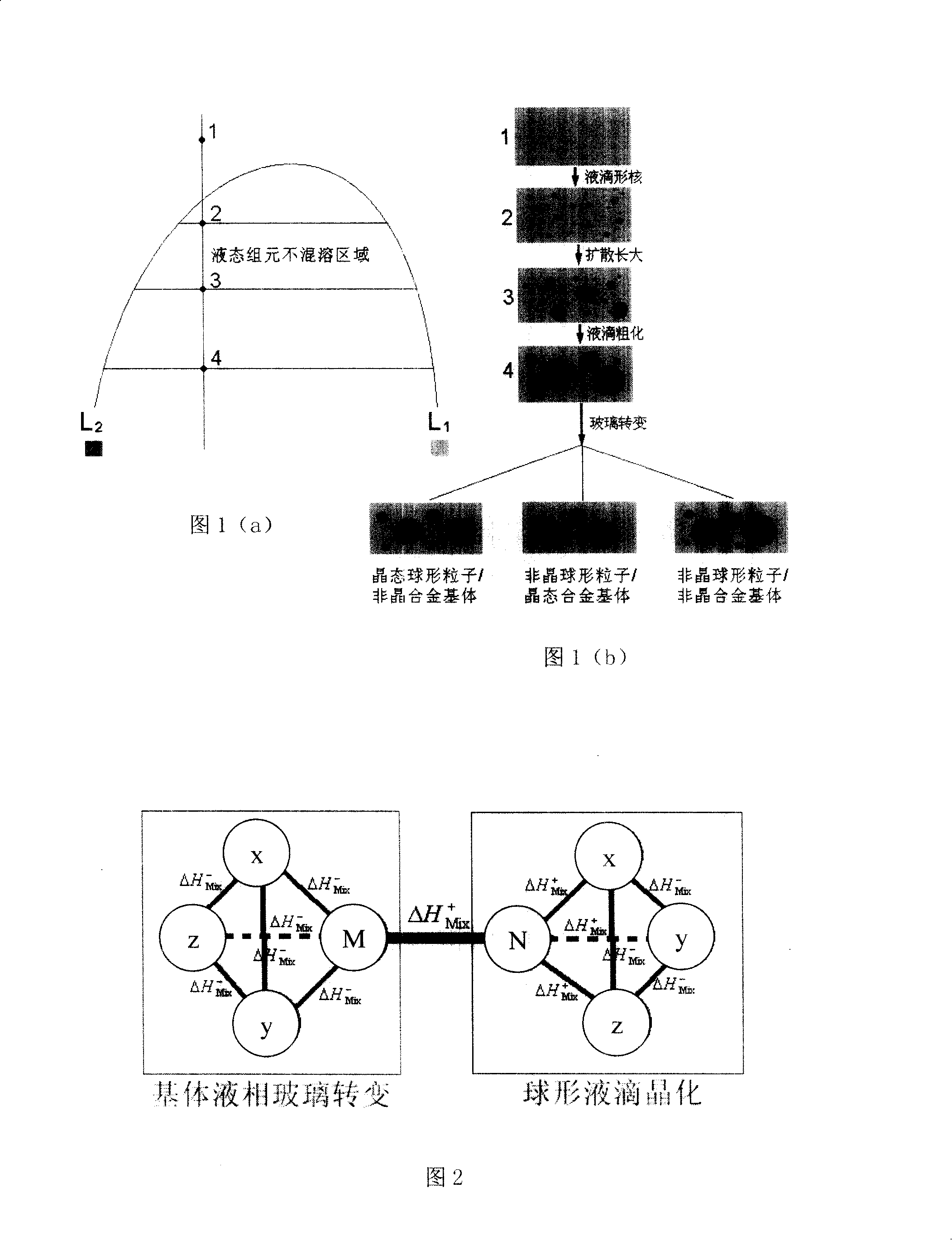

[0019] The invention provides a preparation technology for a new type of amorphous composite material. Based on the metallurgical characteristics of immiscible alloys having immiscible regions of liquid components, through alloy type selection and chemical composition optimization design, crystalline alloy spherical particles / non-crystalline alloys can be obtained. There are three different types of composite materials: crystalline alloy matrix type, amorphous alloy spherical particle / crystalline alloy matrix type and amorphous alloy spherical particle / amorphous alloy matrix type. Its characteristic is that before the glass transition occurs in the alloy melt, the single-phase alloy melt first undergoes a liquid-liquid phase transition, forming two immiscible two-liquid phases L 1 and L 2 , where a liquid phase L 2 Distributed in another liquid phase L in the form of spherical droplets 1 in the matrix; during subsequent rapid cooling, the matrix liquid phase L 1 or disperse...

Embodiment 1

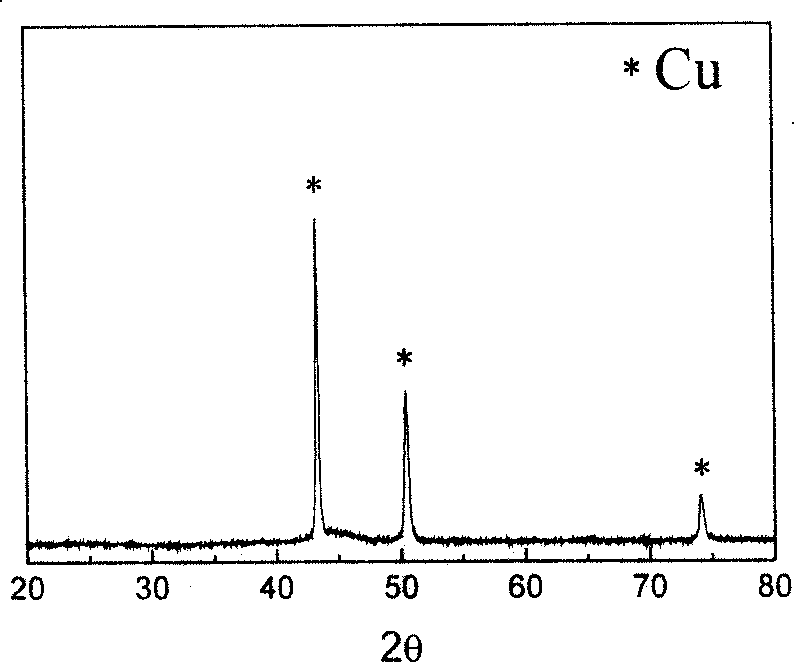

[0034] Using Fe-B master alloy and commercially available pure metal Cu, Fe, Si, B elements such as rods, blocks, ingots, plates and other bulk materials (purity higher than 99.9%) as the starting material, in titanium passivated argon Arc melting under gas atmosphere to form a master alloy ingot, the alloy composition (atomic percentage, the same below) is Cu 30 Fe 56 Si 7 B 7 . The master alloy ingot needs to be arc-melted several times to ensure the uniformity of the composition. Take an appropriate amount of master alloy material and place it in a quartz crucible with a nozzle, re-melt the alloy melt by induction heating under an argon atmosphere (cooling speed is 10 4 ~10 6 K / s) prepared as thin strips. The inner diameter of the quartz crucible is 14mm, the diameter of the nozzle is 0.7mm, the distance between the nozzle and the surface of the single roller is 0.3mm, and the linear speed of the single roller is 50m / s. The width of the thin strip prepared by the sin...

Embodiment 2

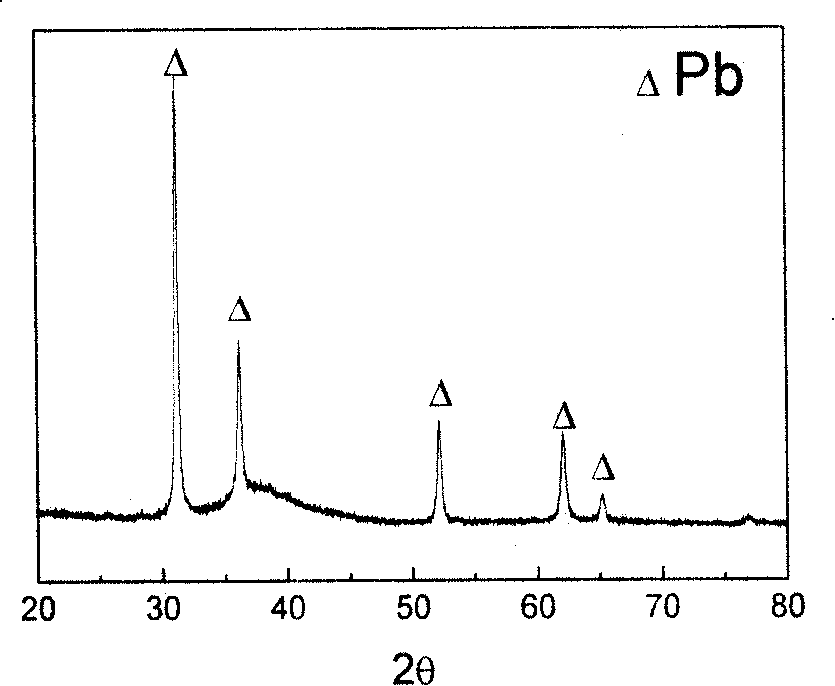

[0037] Using commercially available pure metals Al, Pb, Ni, Y, Co elements such as rods, blocks, ingots, plates and other bulk materials (purity higher than 99.9%) as starting materials, the same smelting method as in Example 1 was used to prepare Al 80.75 Pb 5 Ni 4.75 Y 7.6 co 1.9 Master alloy, prepare thin strip (cooling speed is 10 4 ~10 6 K / s). XRD, SEM results see Figure 3b and Figure 4b. The results show that the ribbon is composed of an amorphous AlNiCoY alloy matrix (in the AlNiCoY alloy matrix, the sum of the elements Al, Ni, Co, and Y accounts for 98.6% of the atomic proportion of the matrix, and the rest is Pb element) and crystalline Pb-rich spherical particles ( In the Pb-rich spherical particles, the atomic proportion of Pb accounts for 97.4%, and the rest are Al, Ni, Co, and Y elements. The atomic proportion of Al accounts for 0.2%, the atomic proportion of Ni accounts for 0.7%, the atomic proportion of Co accounts for 0.12%, and the atomic proportion of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com