Non-air throttle engine and method for controlling power and maintaining constant pressure and contractive pressure and evading explosion

A technology of engine and compression pressure, which is applied in the direction of engine control, electrical control, engine ignition, etc., and can solve problems such as inability to obtain compression pressure, poor adjustment of compression pressure, and inability to maintain optimal working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

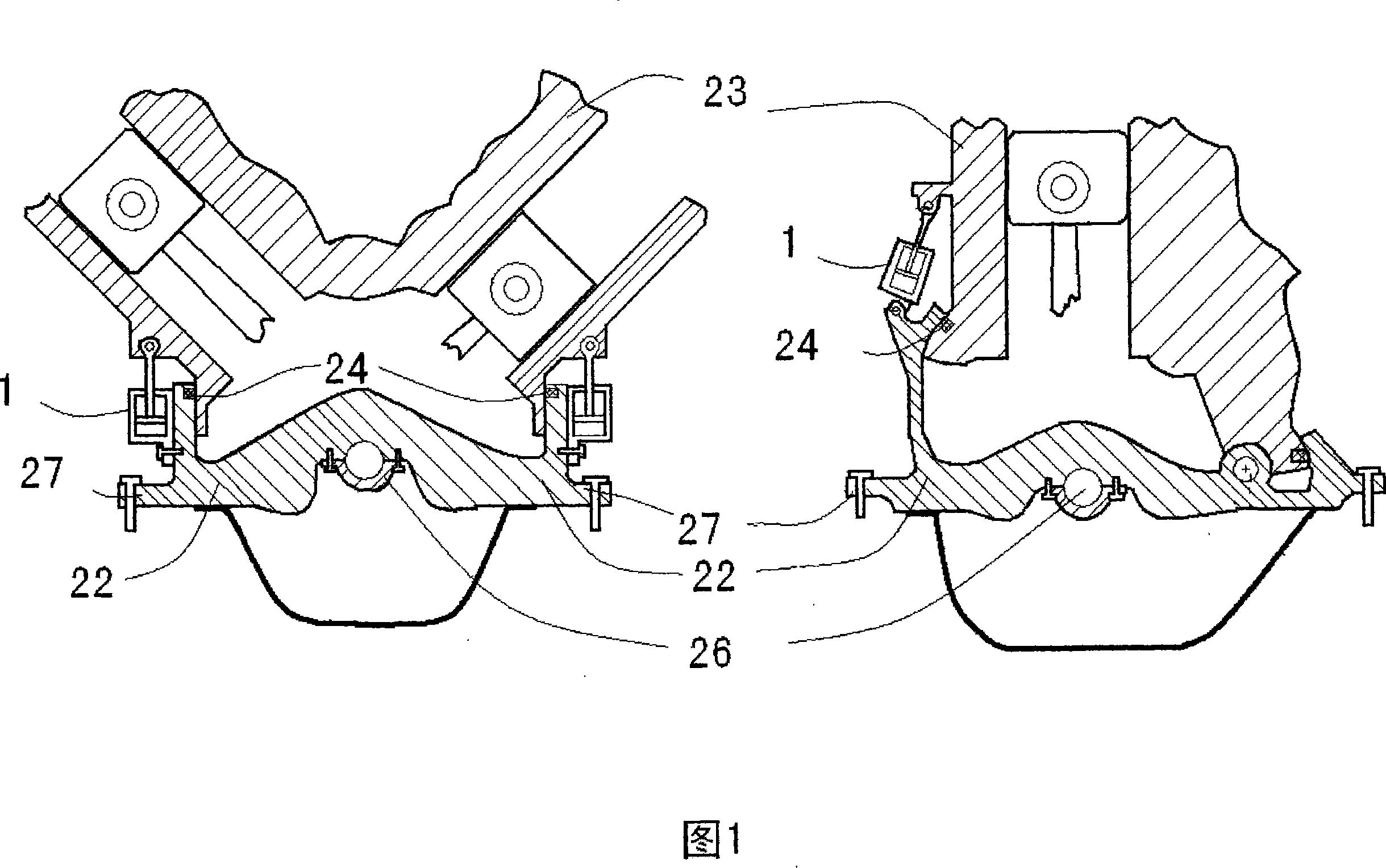

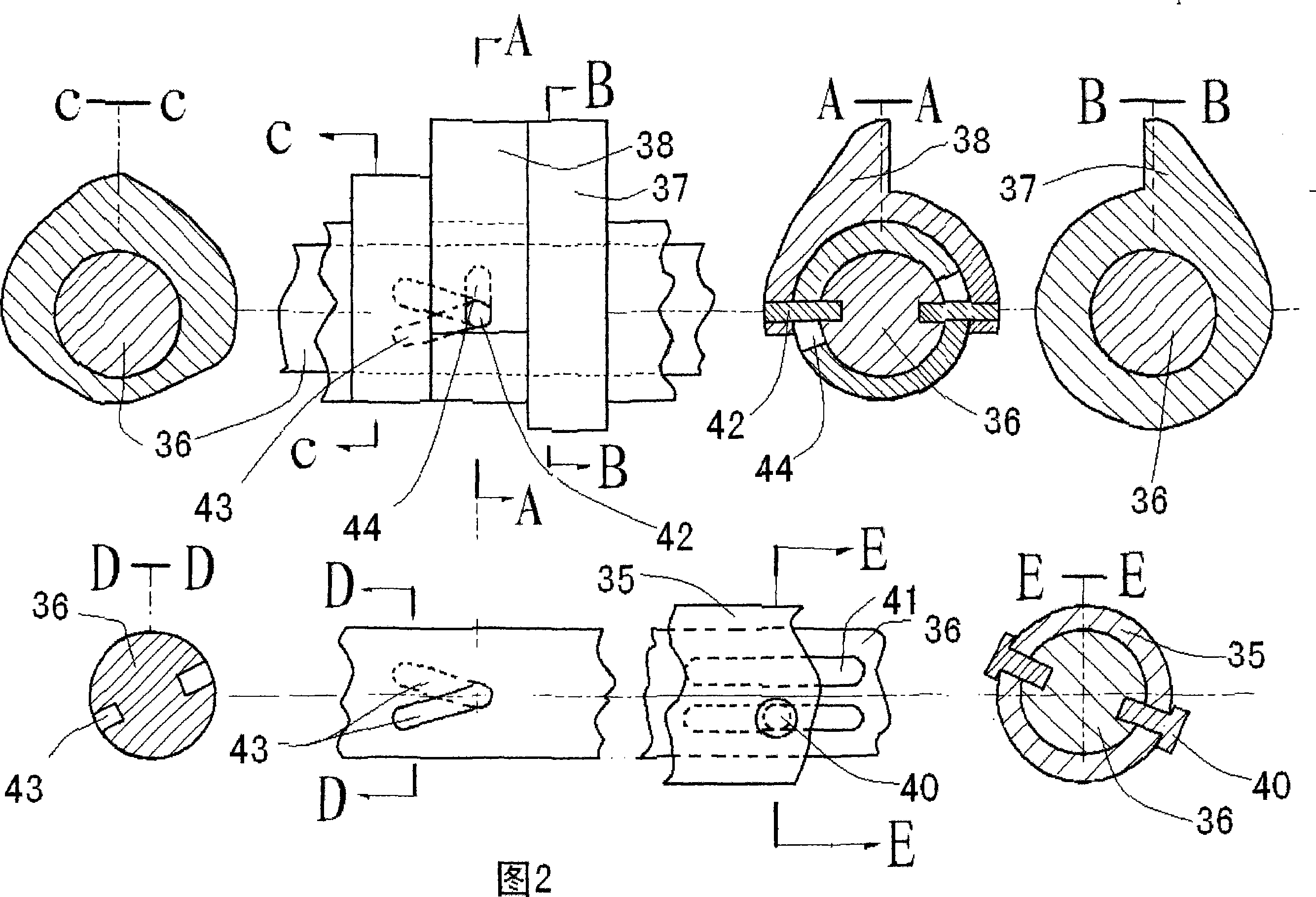

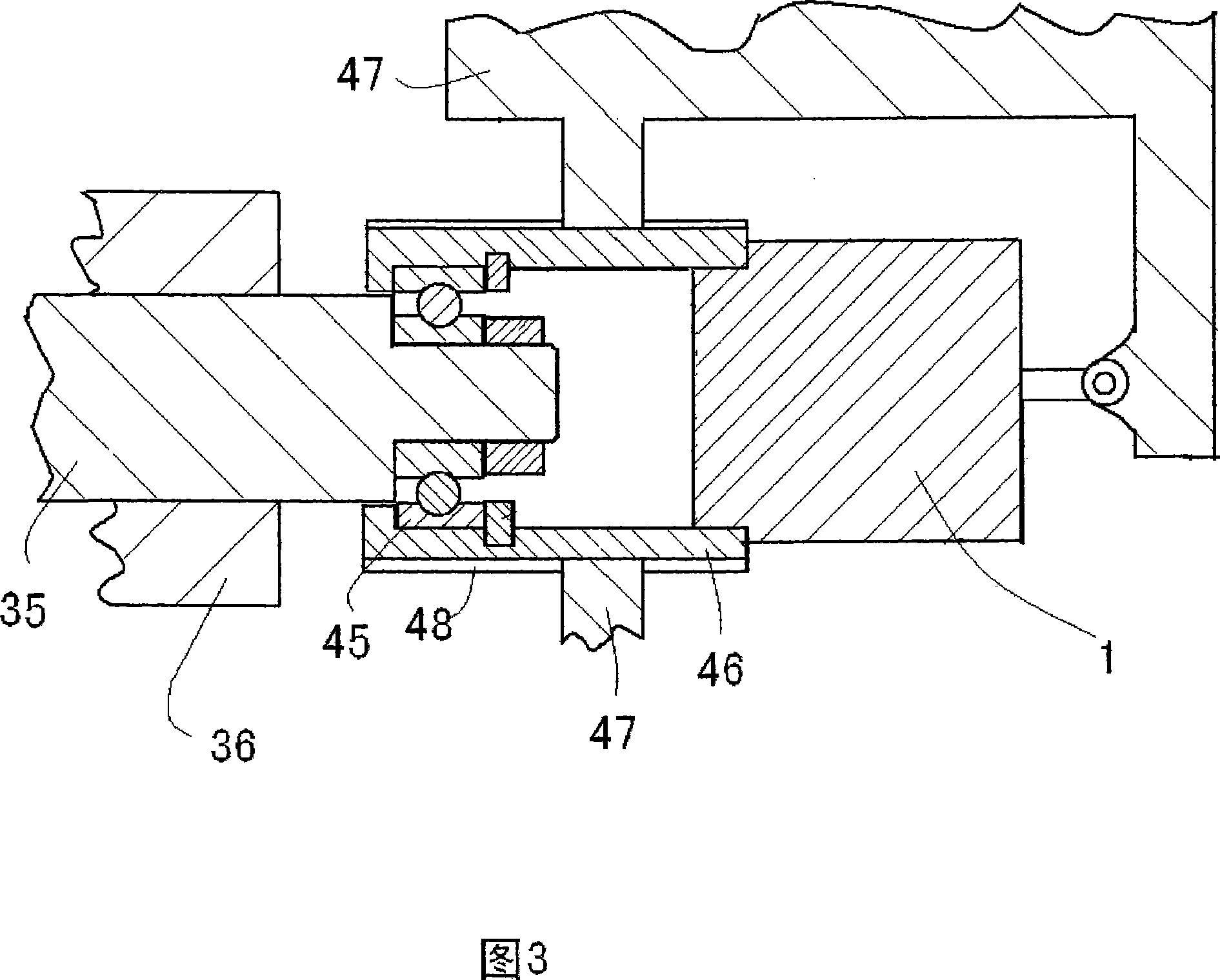

[0069] The engine consists of an electronic control system, a compression pressure adjustment system, an upper and lower cylinder moving device, a special electromagnetic valve (including an electromagnetic hydraulic valve) that generates an exhalation (expiration) stroke, an air distribution system for the control system, and other necessary systems. composition. A preferred example is: the executive mechanism of the upper and lower cylinder moving device is controlled by the regulation pressure instruction of the compression pressure adjustment system, and its electromagnetic valve is controlled by the accelerator pedal signal. Another implementation of the second preferred embodiment is: the actuator of the upper and lower cylinder moving device is controlled by the accelerator pedal signal, and the combined cam mechanism is controlled by the regulation pressure instruction of the compression pressure adjustment system.

[0070] The third preferred embodiment of the recipro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com