Rotation tractor for plastic pipe production line

A technology for plastic pipes and production lines, applied in the direction of tubular items, other household appliances, household appliances, etc., can solve problems affecting the quality of pipes, discounts on production efficiency, yellow lines from pipes, etc. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

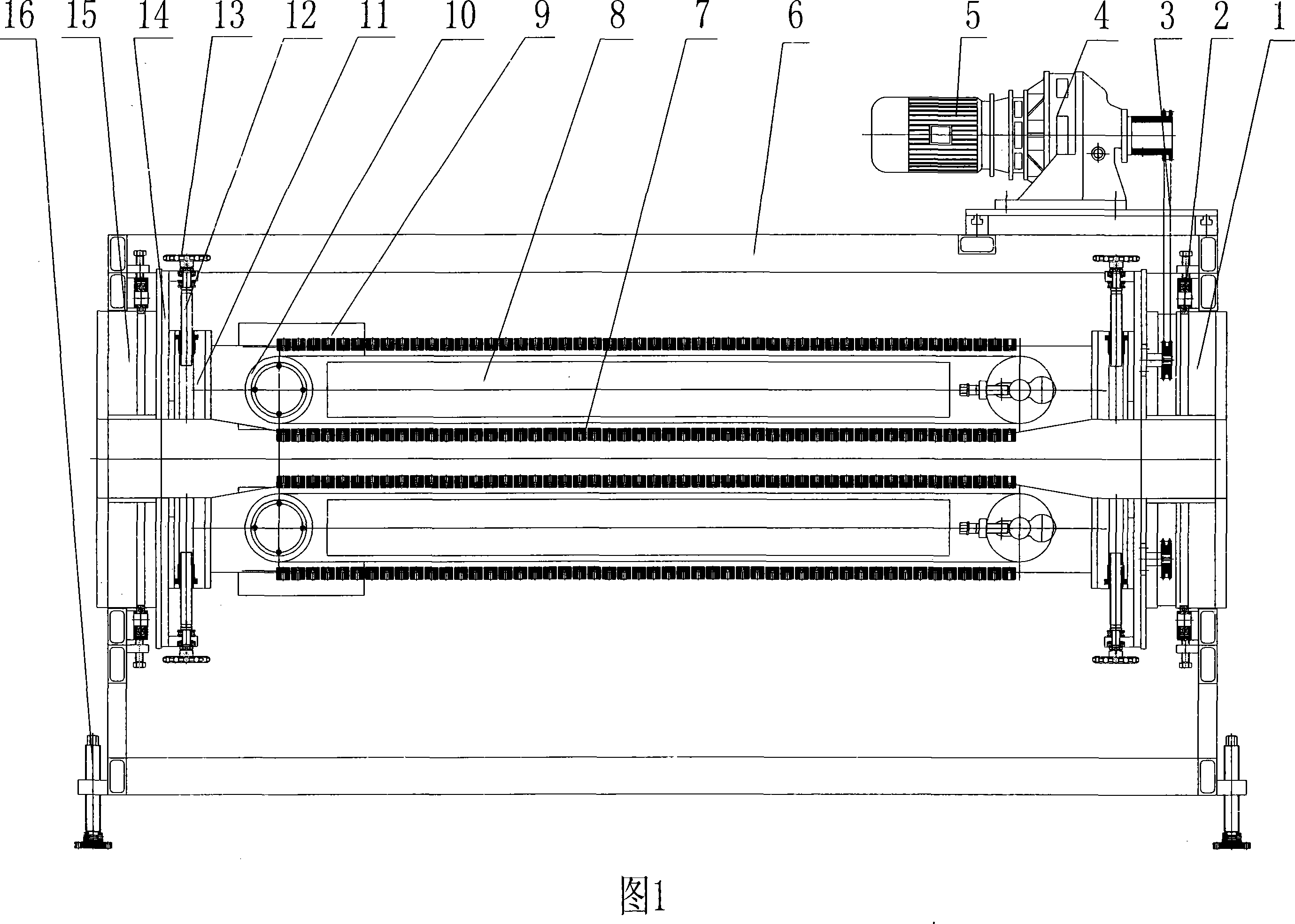

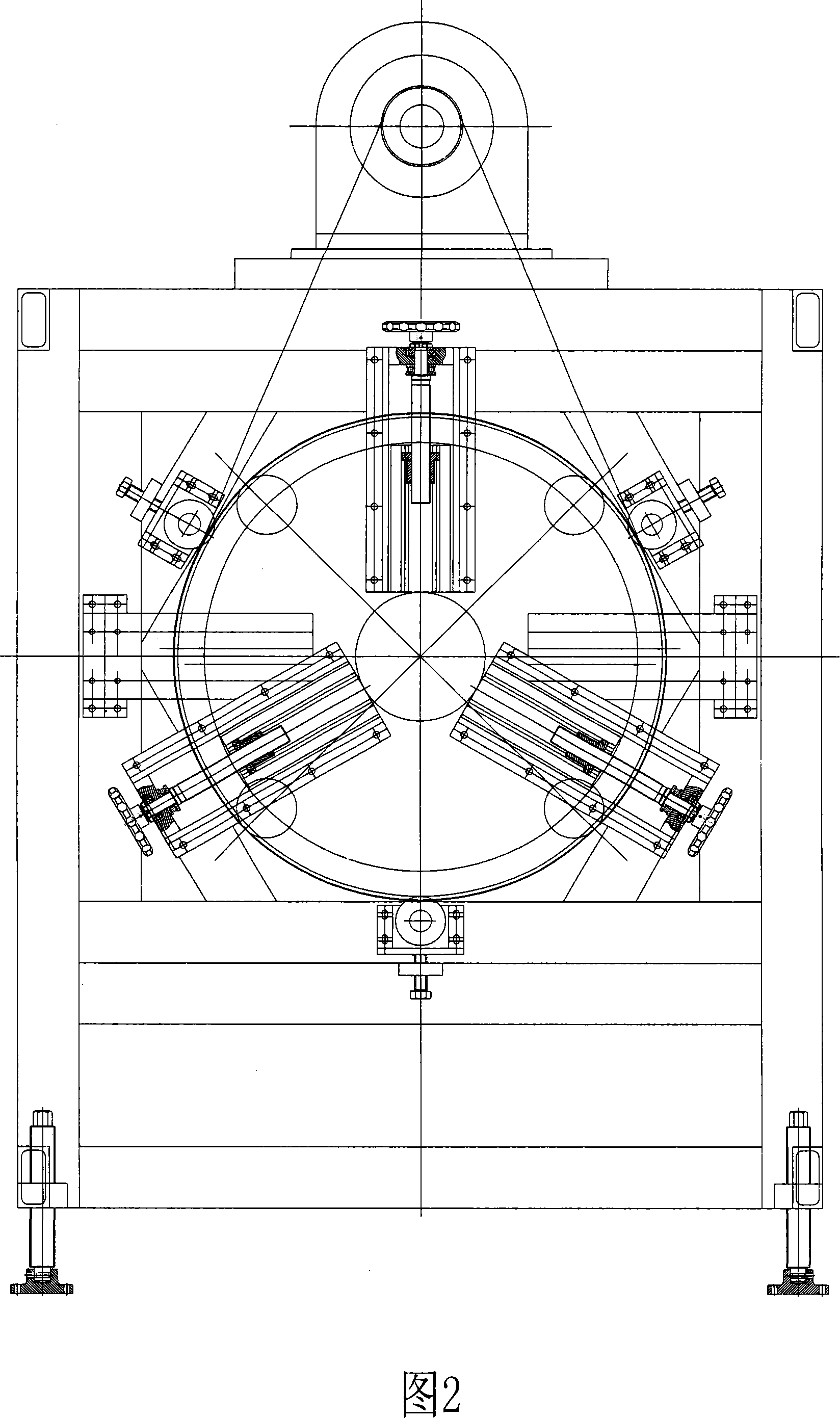

[0021] The structural representation of the present invention is as shown in accompanying drawing 1, 2, and the parts of the present invention are arranged on the frame 6, and can adjust the center height position of tractor by center height lifting mechanism 16, and the traction drive system 9 of tractor is directly installed On the side plate of the crawler frame 8, each crawler belt 7 has a single driving system 9, and the driving system 9 directly drives the traction sprocket 10, and the structure is simple and compact. The sliding seats 14 at the two ends of the crawler belt 7 are fixed on two rotating discs 1, 15 front and rear, and the rotating discs 1, 15 are supported and positioned by three support bearings 2. The rotation of the front rotary disk 1 is driven by a rotary motor 5, and the power of the rotary motor 5 drives the front rotary disk 1 to rotate thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com