Special masonry mortar for aerated concrete and construction method thereof

A technology of masonry mortar and construction method, which is applied in the field of construction, can solve the problems of different thermal conductivity, etc., and achieve the effects of improving early strength, good thermal insulation effect, and delaying the initial setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In every 1000 parts of special masonry mortar for aerated concrete, the parts by weight of each component are: in every 1000 parts of mortar, the parts by weight of each component are: cement 210, gypsum 50, quicklime 180, fly ash 558.5, aluminum powder Paste 0.10, retarder 0.40, methylcellulose 1.0.

[0040] Among them, the physical performance requirements of fly ash are: 88 micron sieve allowance ≤ 15%, specific gravity ≤ 2.1, density ≤ 640kg / m 3 , Loss on ignition ≤ 15%. The physical performance requirements of cement are: label: 425#, loose density 1000-1300kg / m 3 , Compressive strength 7d 42.5Mpa, flexural strength 28d6.5Mpa, fineness 88 micron sieve allowance ≤ 10%, specific surface area ≥ 3000cm2 / g, initial setting time ≥ 45min, final setting time ≤ 10h.

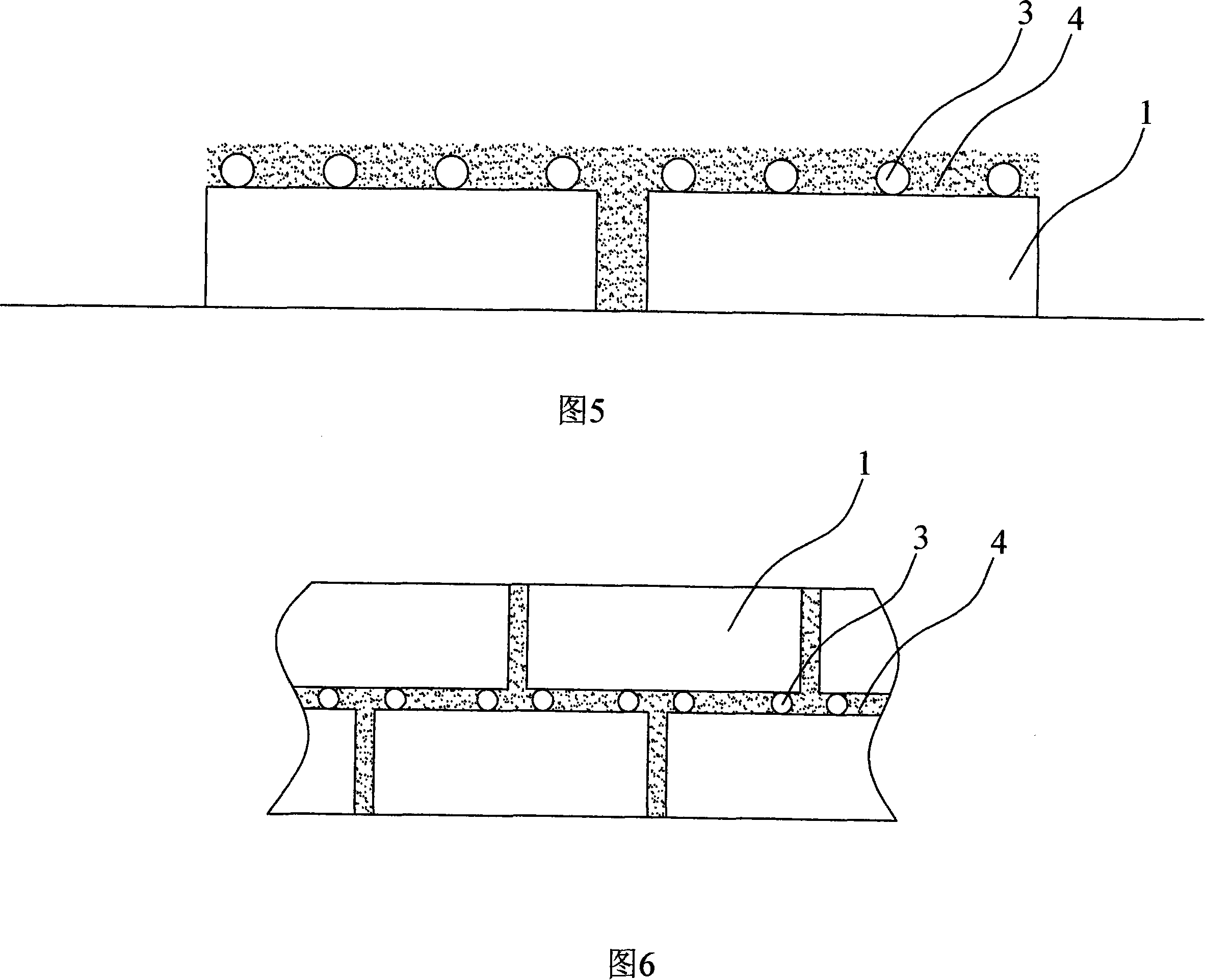

[0041] Referring to Fig. 5 and Fig. 6, this embodiment provides a construction method for the above-mentioned special masonry mortar for aerated concrete, including the following steps:

[0042] a. Measure ...

Embodiment 2

[0049] In every 1000 parts of special masonry mortar for aerated concrete, the parts by weight of each component are: cement 180, gypsum 50, quicklime 138.6, fly ash 630, aluminum powder paste 0.07, retarder 0.33, methyl cellulose 1.0 weight share.

[0050]Wherein, the physical performance requirements of fly ash and cement are the same as those in Example 1.

[0051] Referring to Fig. 5 and Fig. 6, this embodiment provides another technical solution of the construction method of the above-mentioned special masonry mortar for aerated concrete: including the following steps:

[0052] a. Measure various raw materials according to the formula;

[0053] b. Stir according to the ratio of 1000 kg of mortar and 515 kg of water;

[0054] d. Construction grout, the thickness of mortar 4 is 14mm, as shown in Figure 5;

[0055] d. Sprinkle fly ash ceramsite evenly around the surface of mortar 4 .

[0056] After the above steps are completed, the aerated concrete can be built. The fly...

Embodiment 3

[0059] In every 1000 parts of special masonry mortar for aerated concrete, the parts by weight of each component are: cement 250, gypsum 62, quicklime 136.18, fly ash 550, aluminum powder paste 0.12, retarder 0.5, methyl cellulose 1.2 weight share.

[0060] Wherein, the physical performance requirements of fly ash and cement are the same as those in Example 1.

[0061] The construction method of special masonry mortar for air-entrained concrete can adopt one of Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com