Humic acid slowly available fertilizer and preparation method thereof

A humic acid and fertilizer technology, applied in the direction of organic fertilizers, fertilizer mixtures, fertilization devices, etc., can solve the problems of inaccurate evaluation of long-term application risks, expensive coating materials, complicated production processes, etc. Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

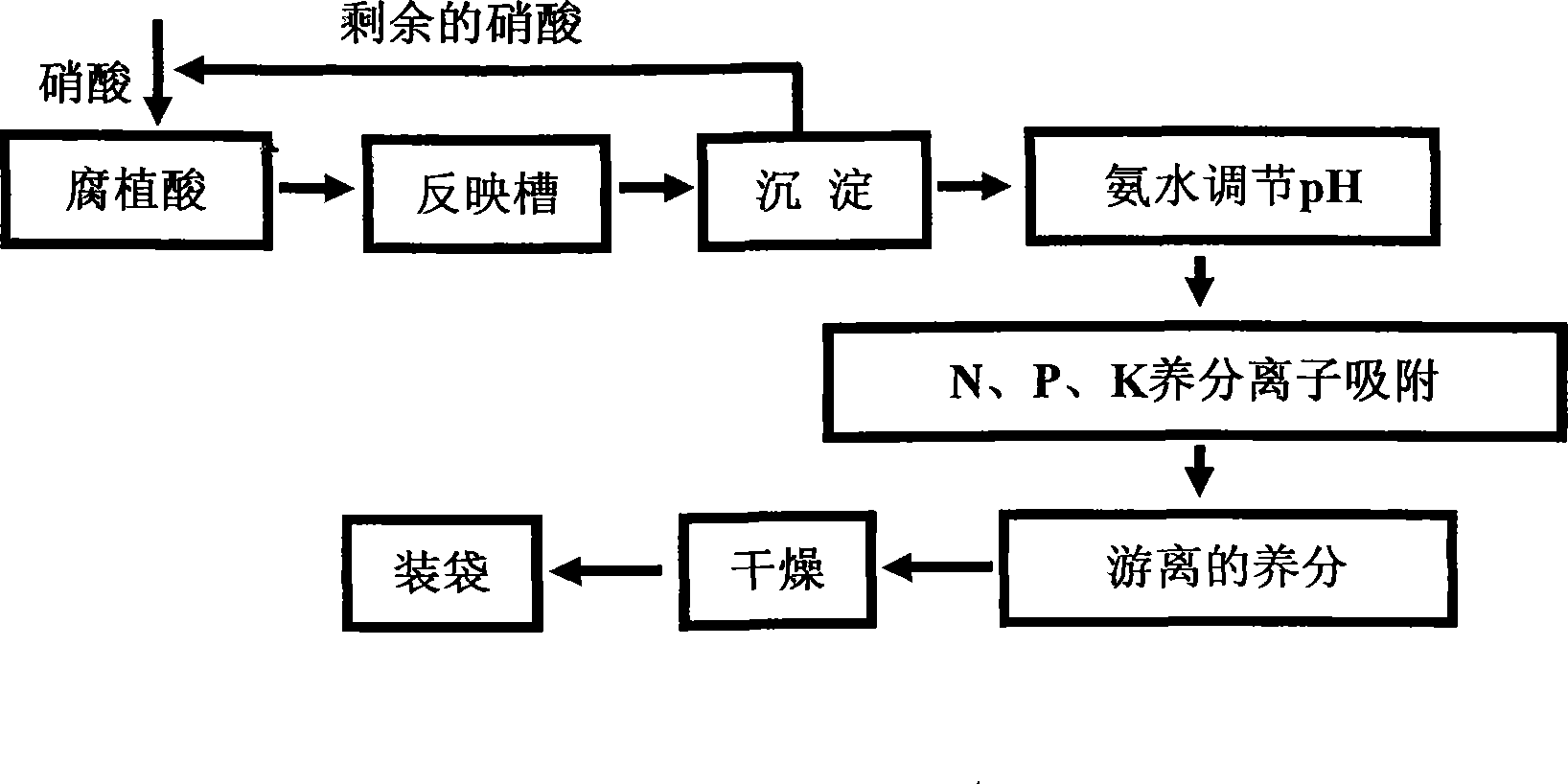

Image

Examples

Embodiment 1

[0017] Embodiment 1: prepare humic acid slow-acting fertilizer, the steps are as follows:

[0018] (1). Activation of humic acid: add lignite and nitric acid into the reactor, stir, make it react, stir after 20min, filter; wherein, the concentration of nitric acid is 40%, and the ratio of lignite to nitric acid is 0.8kg: 1L;

[0019] (2). Adjust pH: Add concentrated ammonia water to the filtered material to adjust pH to 8;

[0020] (3). Add fertilizer: add nitrogen fertilizer, phosphate fertilizer, and potassium fertilizer to the humic acid after pH adjustment, and stir for 30 minutes. Among them, the nitrogen fertilizer is ammonium chloride, the phosphate fertilizer is monoammonium phosphate, and the potassium fertilizer is potassium sulfate, humic acid, nitrogen element , phosphorus, and potassium in a ratio of 100:7:2:11.

[0021] When in use, mix with urea, dry, after bagging, apply to Chinese cabbage, use no fertilization as blank control, to apply common fertilizer (thi...

Embodiment 2

[0026] Embodiment 2: prepare humic acid slow-acting fertilizer, the steps are as follows:

[0027] (1). Activation of humic acid: add lignite and nitric acid in the reactor, stir, make it react, after stirring for 45min, filter; wherein, the concentration of nitric acid is 25%, and the ratio of lignite to nitric acid is 1kg: 1L;

[0028] (2). Adjust pH: Add concentrated ammonia water to the filtered material, the ratio of filtered material to concentrated ammonia water is 50kg: 3L;

[0029] (3). Add fertilizer: add nitrogen fertilizer, phosphate fertilizer, and potassium fertilizer to the humic acid after pH adjustment, and stir for 45 minutes. Among them, the nitrogen fertilizer is ammonium sulfate, the phosphate fertilizer is superphosphate, and the potassium fertilizer is potassium chloride, humic acid, and nitrogen. , phosphorus, and potassium in a ratio of 100:9:2:9.

[0030] When used, mix with urea, dry and apply to crops.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com