Water resistant patch preparation

A product and patch technology, applied in the field of waterproof patch products, can solve the problems of not being able to ensure sufficient adhesion of the skin surface, easy to generate wrinkles, and reduce performance without warning, so as to improve the removal performance, prevent adhesion to clothing, and inhibit washing. Lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126]

[0127] Under an inert gas atmosphere, 2-ethylhexyl acrylate (95 parts by weight), acrylic acid (5 parts by weight) and benzoyl peroxide (0.2 parts by weight) were solution polymerized in ethyl acetate at 60°C, thereby An acrylic adhesive solution is provided.

[0128] In the presence of ethyl acetate, the acrylic adhesive, the organic liquid component (isopropyl palmitate) and the drug (isosorbide dinitrate, a therapeutic drug for angina pectoris) were mixed at a ratio of 43:40:17. weight ratio mix. In addition, CORONATE HL (manufactured by Nippon Polyurethane Industry Co., Ltd.) was mixed as a crosslinking agent at a solid content of 0.15 parts by weight with respect to 100 parts by weight of the acrylic adhesive, thereby providing a solid content for forming the adhesive layer. combination.

[0129]

[0130] The above composition was applied to the easy-release surface of a release liner (thickness 75 μm) made of PET so that the thickness of the adhesive layer...

Embodiment 2

[0134]

[0135] In the presence of hexane, polyisobutene 1 with high molecular weight (viscosity average molecular weight 4,000,000), polyisobutylene 2 with low molecular weight (viscosity average molecular weight 80,000), tackifier (alicyclic saturated hydrocarbon resin, softening point 100 °C (ring and ball method)), organic liquid components (isopropyl palmitate) and drugs (tulobuterol, bronchodilators) were mixed in a weight ratio of 15:20:20:35:10 to provide Composition of the adhesive layer.

[0136]

[0137] The above composition was applied to the easy-release surface of a PET release liner (thickness 75 μm) so that the thickness of the adhesive layer after drying was 200 μm, and dried in a drying oven (70° C.) to provide a release liner with an adhesive layer end. The surface with the adhesive layer was laminated on a support, which was a PET film having a thickness of 12 μm, by pressure bonding to provide an adhesive sheet for die-cut patch preparations.

[013...

experiment Embodiment 1

[0161]

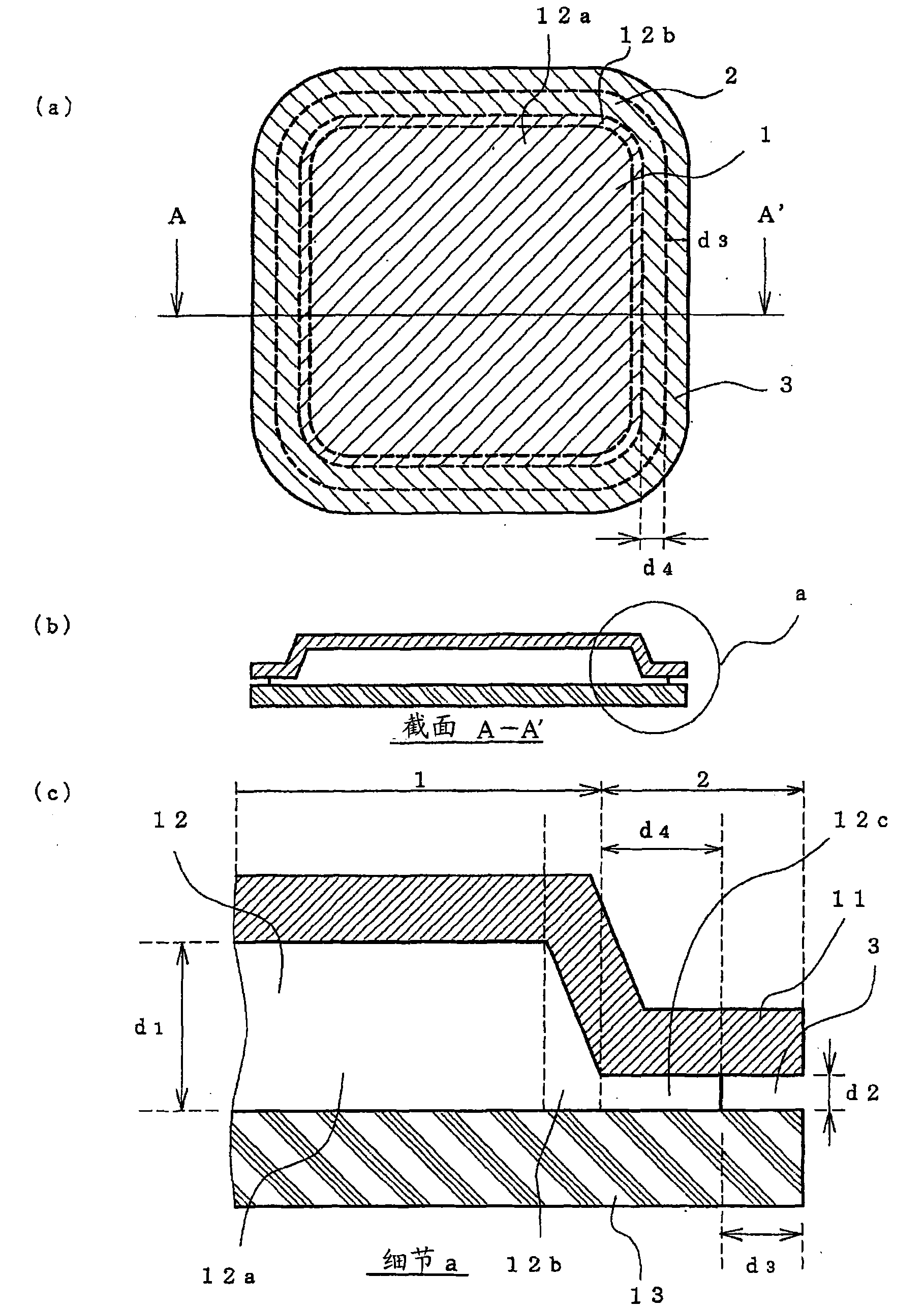

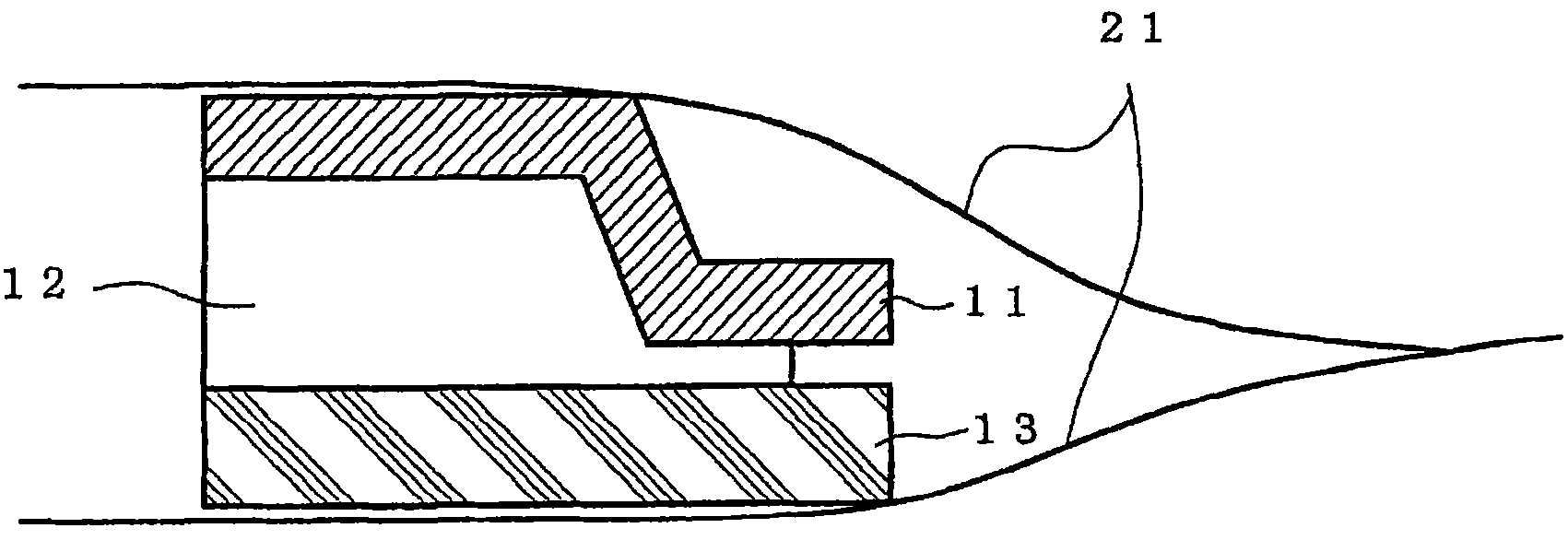

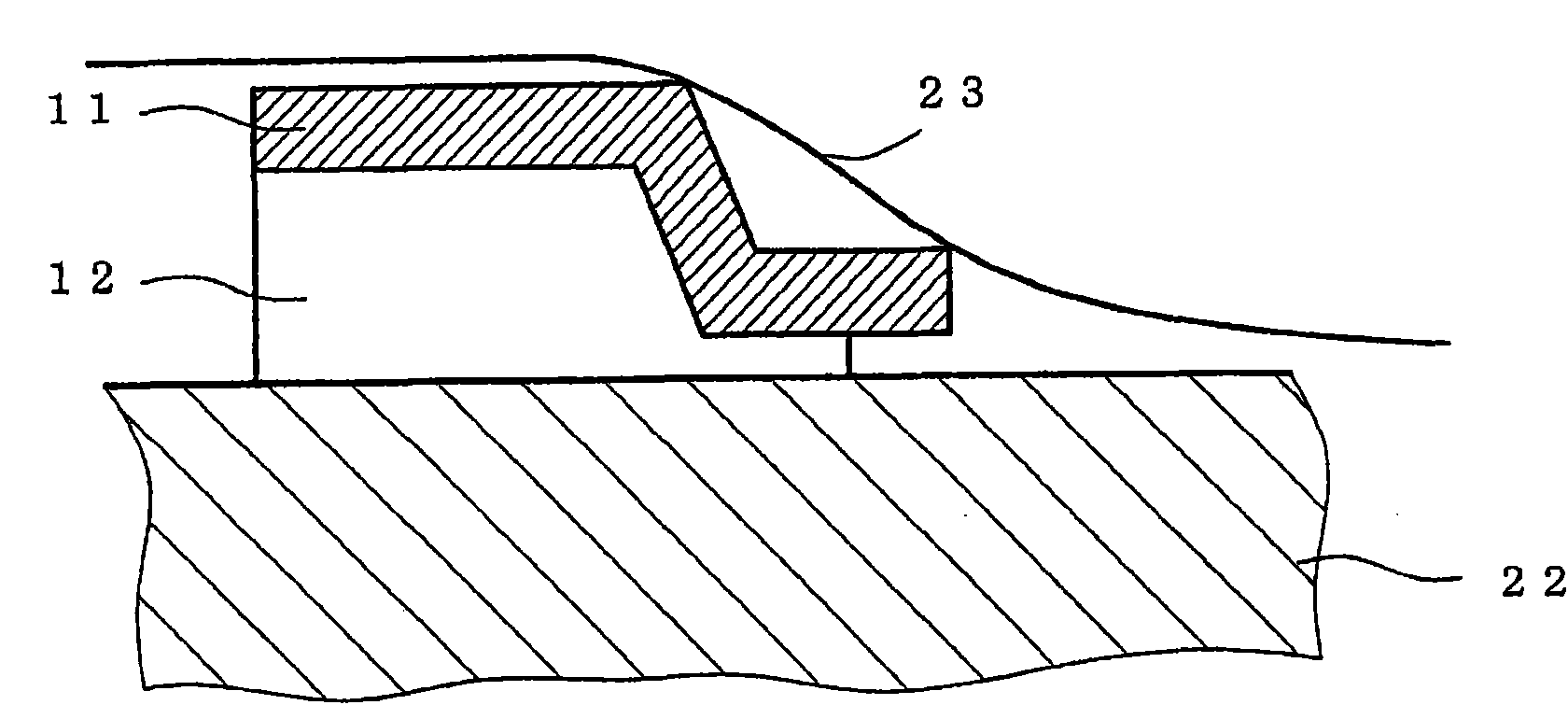

[0162] The patch preparations were cut using a razor for trimming, their cross-sections were observed with a digital microscope (Keyence Corporation, VHX-600, magnification 1000 times), and the thicknesses of the adhesive layers in the peripheral portion and the central portion were measured. Furthermore, the cross-sectional shape of the side end of the adhesive layer was observed, and the distance from the side end of the carrier to the portion of the adhesive layer located closest to the central portion was measured. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com