Preparation method of cyclohexanone oxime

A technology of cyclohexanone oxime and cyclohexanone, which is applied in oxime preparation, organic chemistry and other directions, can solve the problems of incomplete oximation reaction, poisoning of catalytic catalyst, and reduction of reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

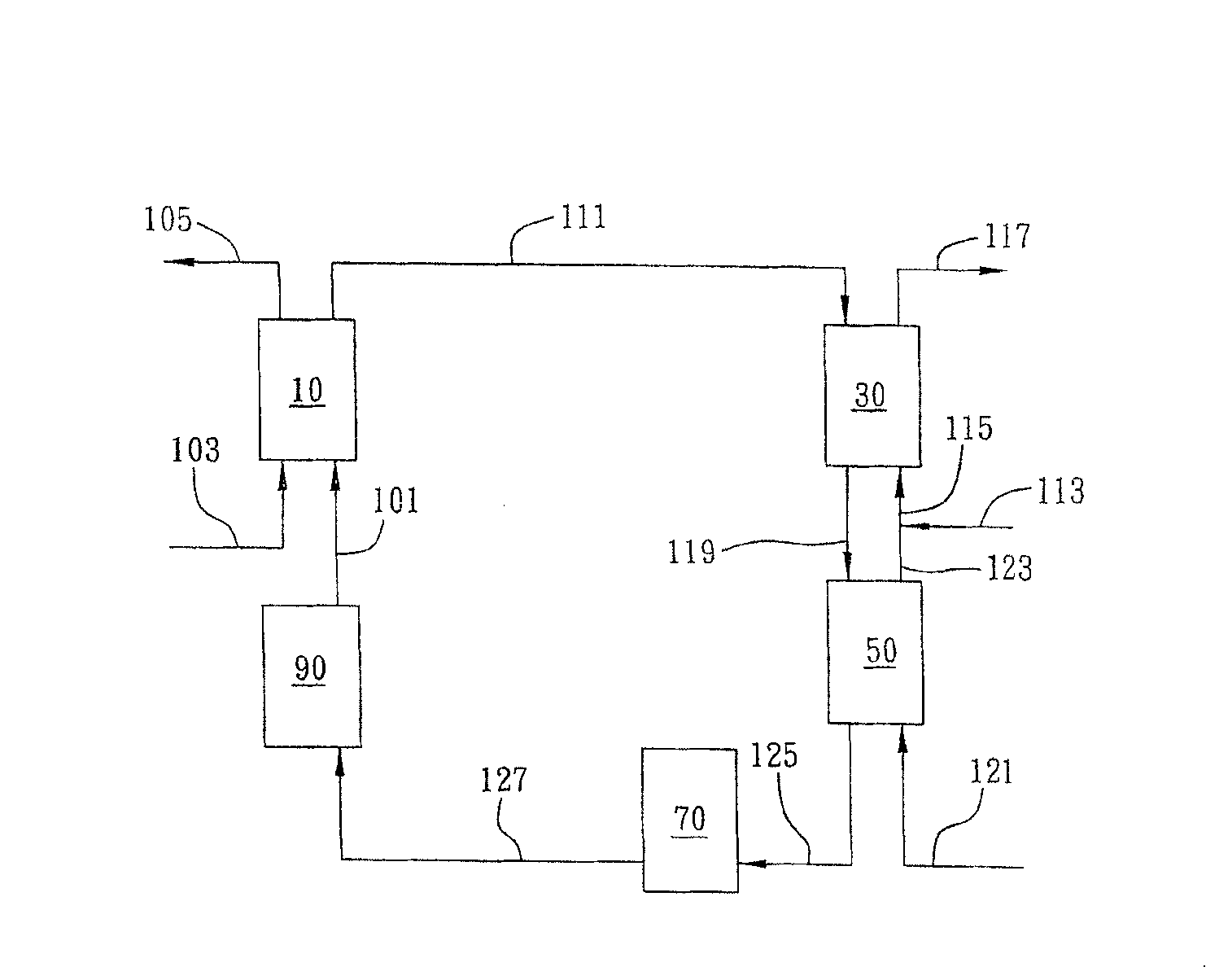

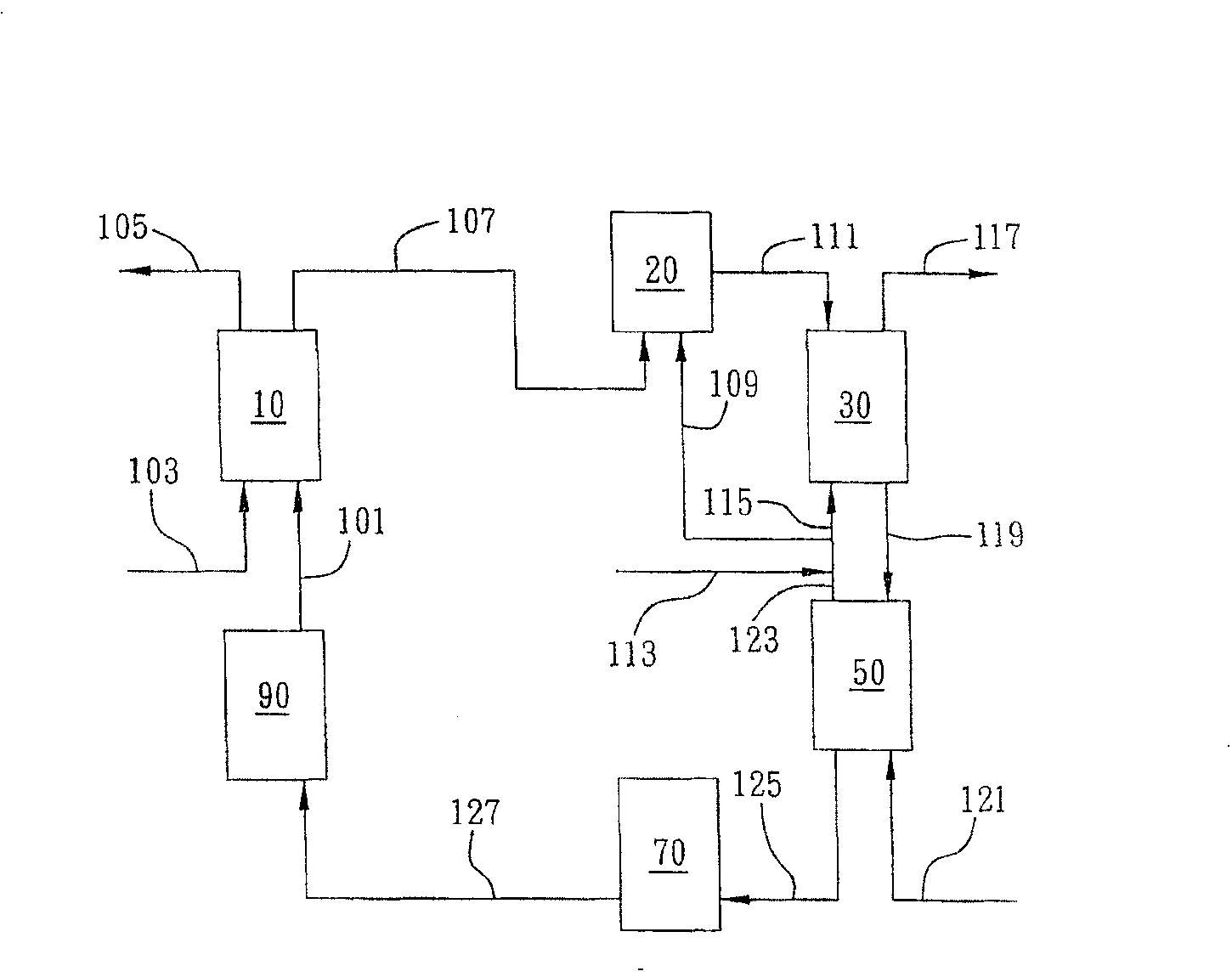

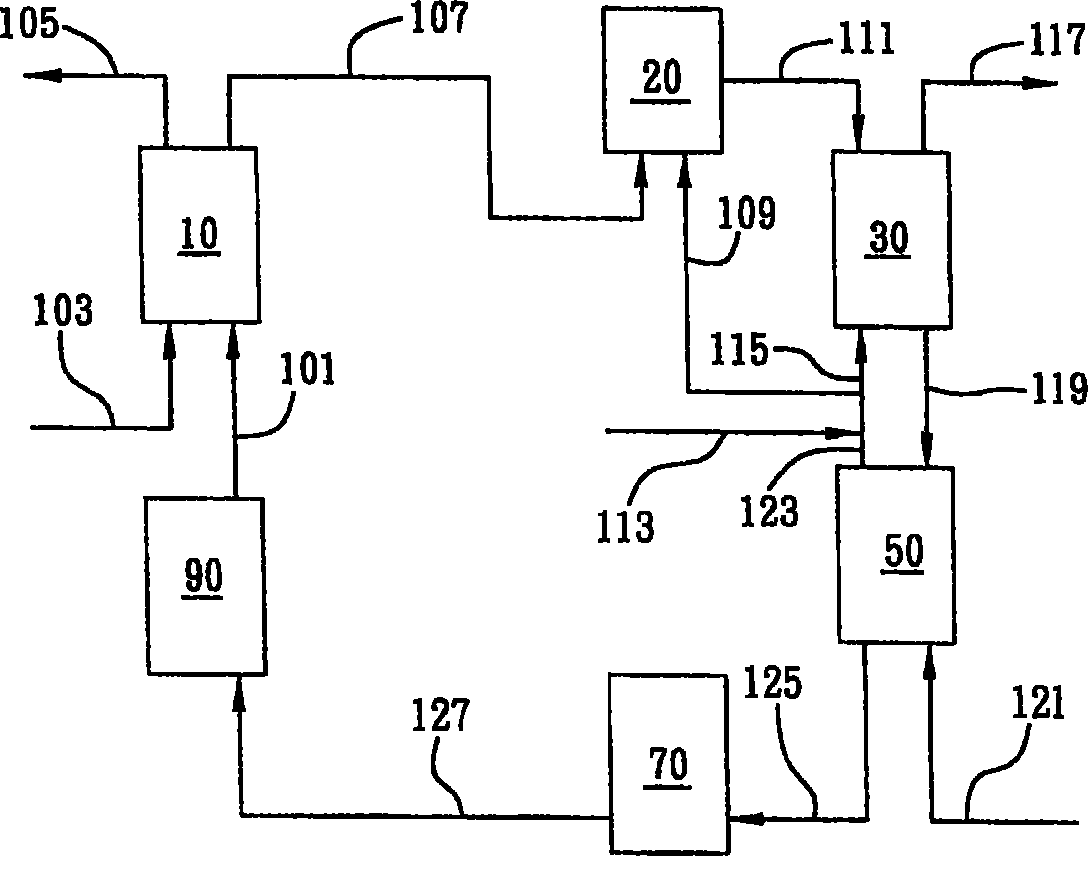

[0013] The preparation method of the invention can be applied in the circulation process of hydroxylamine-oximation. In this cycle process, the phosphate inorganic treatment solution is used as the aqueous reaction medium of the entire cycle. In the hydroxylamine reactor, hydrogen is used to reduce nitrate ions to form hydroxylamine phosphate, and then pre-mixed with part of cyclohexanone in the pre-mixing reactor to reduce The concentration of phosphohydroxylamine is then entered into the oximation reactor for oximation reaction with cyclohexanone to produce cyclohexanone oxime; after removing organic impurities and supplementing the content of nitrate ions, the phosphate inorganic treatment solution is recycled back to hydroxylamine reactor for the next cycle of reaction. Such as figure 2 Shown, in this concrete example, use the hydroxylamine-oximation circulation process of the inventive method to comprise hydroxylamine reactor (10), premix tank (20), oximation tower (30)...

Embodiment 1

[0022] Repeat Comparative Example 1, but the inorganic treatment solution of hydroxylamine phosphate and part of the toluene solution of cyclohexanone are first fed into the premixing reactor in the same direction, and premixed at a temperature of 37 ° C and atmospheric pressure. In the mixed reaction liquid discharged from the premixed reactor, the concentration ratio of hydroxylamine phosphate is reduced to 45% of the original concentration.

[0023] The pre-mixed mixed reaction solution is fed from the top of the oximation tower, and another part of the toluene solution of cyclohexanone is fed from the bottom of the oximation tower. At a temperature of 51 ° C, the oximation reaction is carried out by countercurrent contact. The molar ratio of ketones (total of both parts) was 0.90. From the organic phase of the overflow discharge from the top of the oximation tower per unit time, 1.434 moles (162.0 grams) of cyclohexanone oxime are contained; The concentration is less than...

Embodiment 2

[0028] Repeat Comparative Example 2, but the inorganic treatment solution of hydroxylamine phosphate and part of the toluene solution of cyclohexanone are first fed into the premixing reactor in the same direction, and premixed at a temperature of 37°C and at atmospheric pressure. In the mixed reaction liquid discharged from the premixed reactor, the concentration ratio of hydroxylamine phosphate was reduced to 63% of the original concentration.

[0029] The pre-mixed mixed reaction solution is fed from the top of the oximation tower, and another part of the toluene solution of cyclohexanone is fed from the bottom of the oximation tower. At a temperature of 51°C, the oximation reaction is carried out by countercurrent contact. Hydroxylamine and cyclohexyl The molar ratio of ketones (total of both parts) was 0.90. In the organic phase of the overflow discharge from the top of this oximation tower per unit time, contain 1.614 (182.4 grams) cyclohexanone oxime, in the phosphate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com