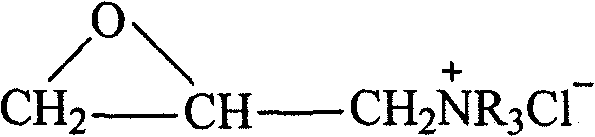

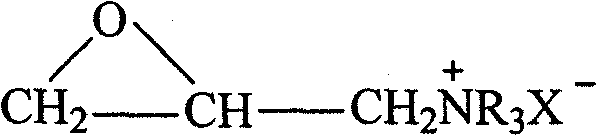

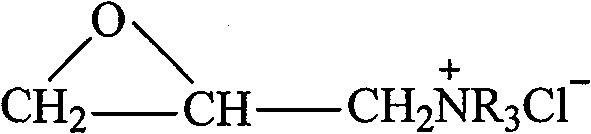

Method for preparing epoxy propyl ionic liquid and polyether-type macroion liquid

A technology of ionic liquid and glycidyl, which is applied in the direction of organic chemistry, can solve the problems of high glass transition temperature, low material conductivity, and difficulty in meeting practical requirements, and achieve the effect of wide electrochemical window and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Mix 1 mole of epichlorohydrin and 1 mole of quinoline, stir and react at 40°C for 8 hours, add 50ml of precipitant, such as diethyl ether, etc. after cooling to room temperature, purify the precipitate to obtain a purple solid, press epichlorohydrin The calculated yield was 73%.

[0040] Dissolve the above product in 100 mL of dimethyl sulfoxide, add 1 mol of ammonium tetrafluoroborate to the above solution, stir and react at 50°C for 24 hours, set aside to settle, filter, evaporate the solvent under reduced pressure to obtain tetrafluoroborate epoxy Propylquinoline Ionic Liquid.

Embodiment 2

[0042]Mix 1 mole of epichlorohydrin and 1.5 moles of quinoline, stir and react at 50°C for 8 hours, add 50ml of precipitant, such as ether, etc. after cooling to room temperature, purify the precipitate to obtain a purple solid, press epichlorohydrin The calculated yield was 88%.

[0043] Dissolve the above product in 100 mL of dimethyl sulfoxide, add 1.2 mol of ammonium tetrafluoroborate into the above solution, stir at 50°C and continue the reaction for 24 hours, then set aside to settle, filter, and evaporate the solvent under reduced pressure to obtain tetrafluoroboric acid Glycidyl quinoline ionic liquid.

Embodiment 3

[0045] Dissolve 2 g of glycidyl quinoline tetrafluoroborate ionic liquid in 50 mL of dimethyl sulfoxide, and add SnCl at 0.1% by weight at 10°C 4 -CF 3 COOH, stirred and reacted for 16 hours, added a precipitant, such as diethyl ether, etc., separated and dried to obtain quinoline tetrafluoroborate-type polyether ionic liquid with a conversion rate of 86%.

[0046] The reaction of other tertiary amine compounds with epichlorohydrin to generate glycidyl ionic liquid chloride salt and its exchange reaction with other anions can also be implemented by a method similar to that of Examples 1 and 2 to prepare a series of compounds containing different cationic groups. Glycidyl ionic liquids with different anionic groups.

[0047] Any other glycidyl ionic liquid can be implemented by a method similar to Example 3 to prepare a series of polyether ionic liquids with different cationic groups and different anionic groups.

[0048] The polymerization of glycidyl ionic liquids catalyzed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com