Environment-friendly type soya-bean ink and preparation technique thereof

A soybean ink, environmentally friendly technology, applied in inks, household appliances, applications, etc., can solve the problems of pollution, waste petroleum-based inks, etc., to avoid environmental pollution, low VOC content, and good deinking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] 1. Eco-friendly soybean ink

[0025] Formula and composition weight ratio are as shown in Table 1:

[0026] Table 1

[0027] Raw Material Royal Red Blue Black

[0028] Polymerized soybean oil 36~38 32~34 34~36

[0029] Refined soybean oil 38~40 40~42 39~41

[0030] Refined tung oil 5~6 5~6 4.5~5.5

[0031] Pigment 18 13 18

[0032] Colloidal calcium carbonate 4 4 4

[0033] Olefin low molecular weight polymerization 2~3 2~3 2~3

[0034] thing

[0035] Cobalt naphthenate drier 0.5~1 0.5~1 0.5~1

[0036] Micronized wax 1.5~2.5 1.5~2.5 1.5~2.5

[0037] Antioxidant (TBHQ) 0.5~1 0.5~1 0.5~1

[0038] Vanilla oil 0.5~1 0.5~1 0.5~1

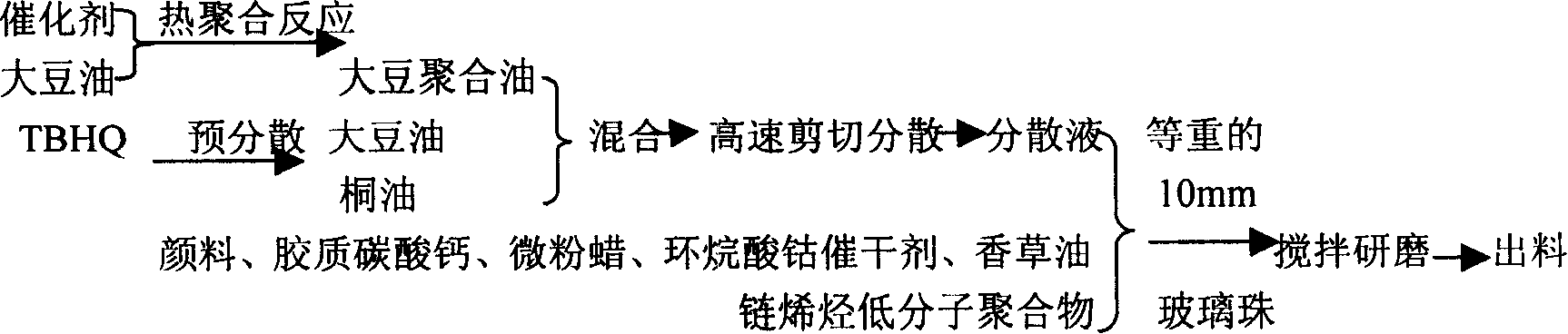

[0039] 2. Preparation method of environmentally friendly soybean ink

[0040] Concrete laboratory small-scale preparation process method is as follows: according to the described environmental protection soybean ink formula,

[0041] Put the used container in a water bath at 65-70°C, add soybean oil first, then add the antioxidant TB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com