Photosensitive gap material for liquid crystal display device, manufacturing method thereof and liquid crystal display device

A technology for a liquid crystal display and a manufacturing method, applied in the directions of photosensitive materials for optomechanical equipment, photolithographic process exposure devices, static indicators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

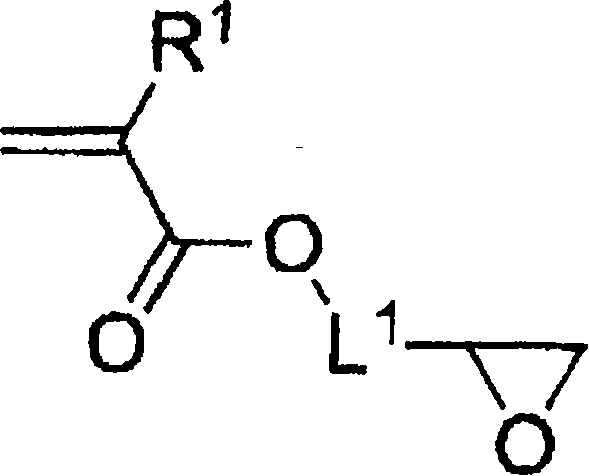

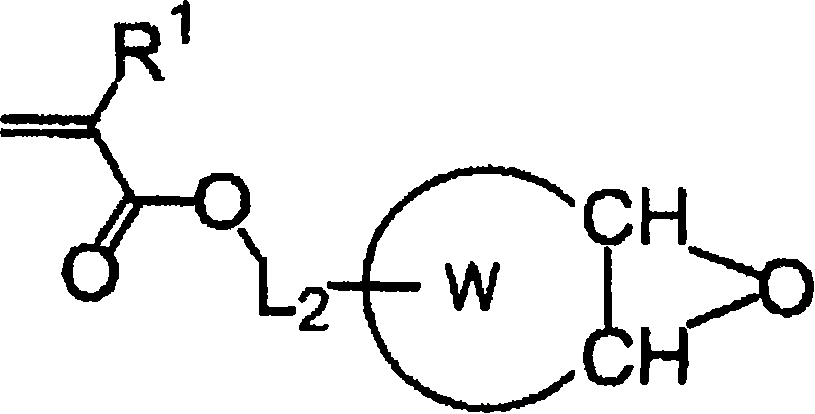

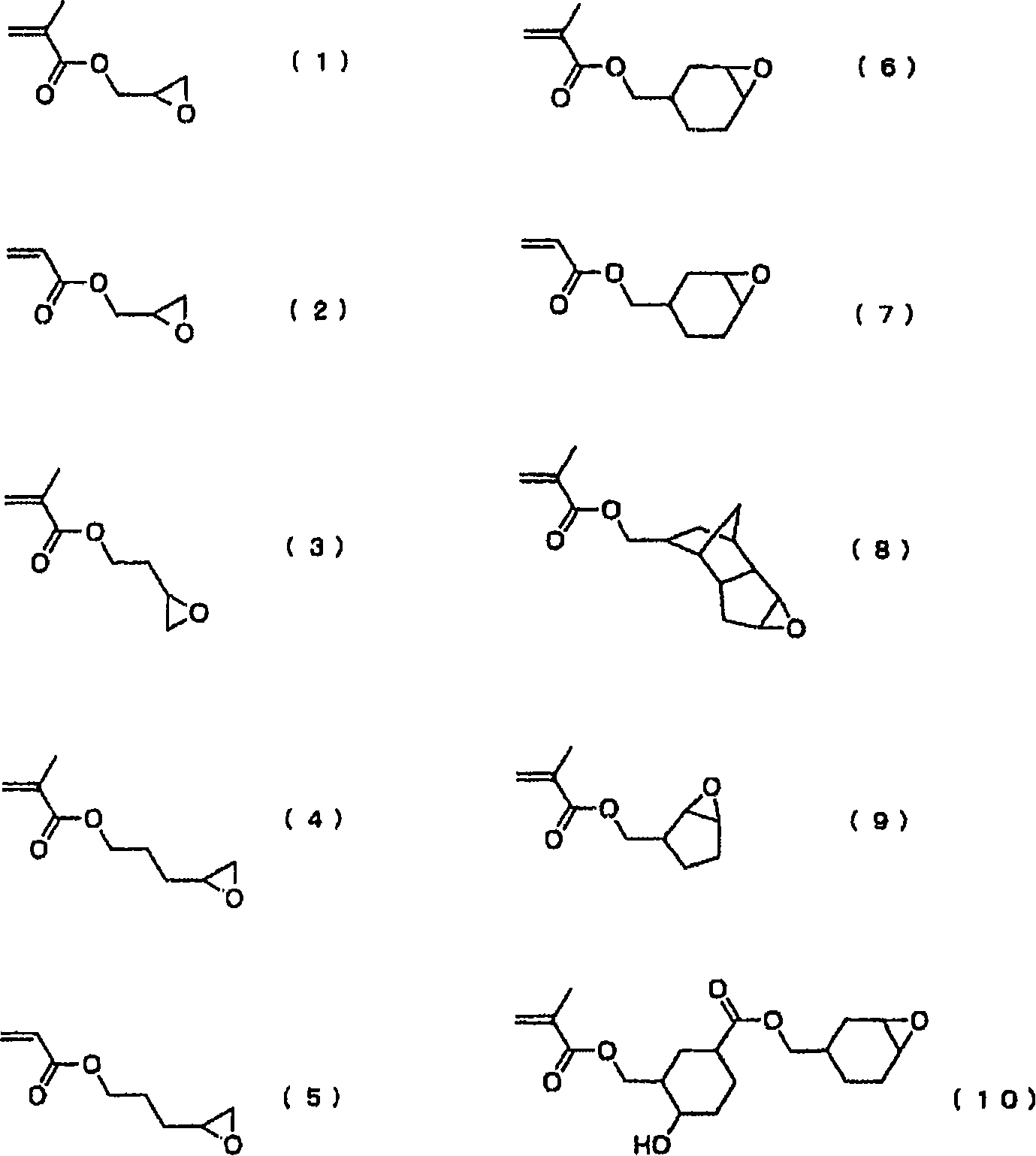

Method used

Image

Examples

Embodiment

[0155] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited by the following examples within the range not exceeding the gist. In addition, unless otherwise specified, "part" and "%" are weight standards.

Synthetic example 1

[0157] Add 5.11 parts of 1-methoxy-2-propanol and 5.11 parts of 1-methoxy-2-propyl acetate to the reaction vessel in advance, raise the temperature to 90°C, and under nitrogen atmosphere, the reaction vessel at 90°C 5.10 parts of styrene, 9.84 parts of methacrylic acid, 1 part of an azo-based polymerization initiator (manufactured by Wako Pure Chemical Industries, Ltd., V-601) and 5.11 parts of 1-methoxy-2-propanol were instilled over 2 hours. and a mixed solution consisting of 5.11 parts of 1-methoxy-2-propyl acetate. After dripping, it was allowed to react for 4 hours to obtain an acrylic resin solution.

[0158]Next, 0.036 parts of hydroquinone monomethyl ether and 0.082 parts of tetraethylammonium bromide were added to the acrylic resin solution, and then 9.28 parts of glycidyl methacrylate was dripped over 2 hours. After dripping, it was reacted at 90° C. for 4 hours while blowing in air, and then a solvent was added to make the solid content concentration 45%, thereby p...

Synthetic example 2

[0162] Add 13.56 parts of 1-methoxy-2-propanol to the reaction vessel in advance, raise the temperature to 90°C, and drip 8.24 parts of cyclohexyl methacrylate, A mixed solution consisting of 9.84 parts of methacrylic acid, 1 part of an azo polymerization initiator (manufactured by Wako Pure Chemical Industries, Ltd., V-601), and 13.56 parts of 1-methoxy-2-propanol. After dripping, it was allowed to react for 4 hours to obtain an acrylic resin solution.

[0163] Next, 0.0415 parts of hydroquinone monomethyl ether and 0.068 parts of tetraethylammonium bromide were added to the acrylic resin solution, and then 9.28 parts of glycidyl methacrylate was dripped over 2 hours. After dripping, react at 90° C. for 4 hours while blowing in air, and then add a solvent so that the solid content concentration becomes 45%, thereby preparing a resin solution represented by the compound P-10 having an unsaturated group ( Solid content acid value: 100 mgKOH / g, Mw: 18,000, 45% solution of 1-met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com