Method for improving photolithography exposure energy homogeneity using grey level compensation

A technology of exposure energy and uniformity, which is applied in the field of exposure energy uniformity correction of maskless lithography machines, can solve difficult problems such as light energy utilization rate and light uniformity, design, processing requirements and difficulty, etc., to achieve Effects of shortened modulation, simple control method, and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

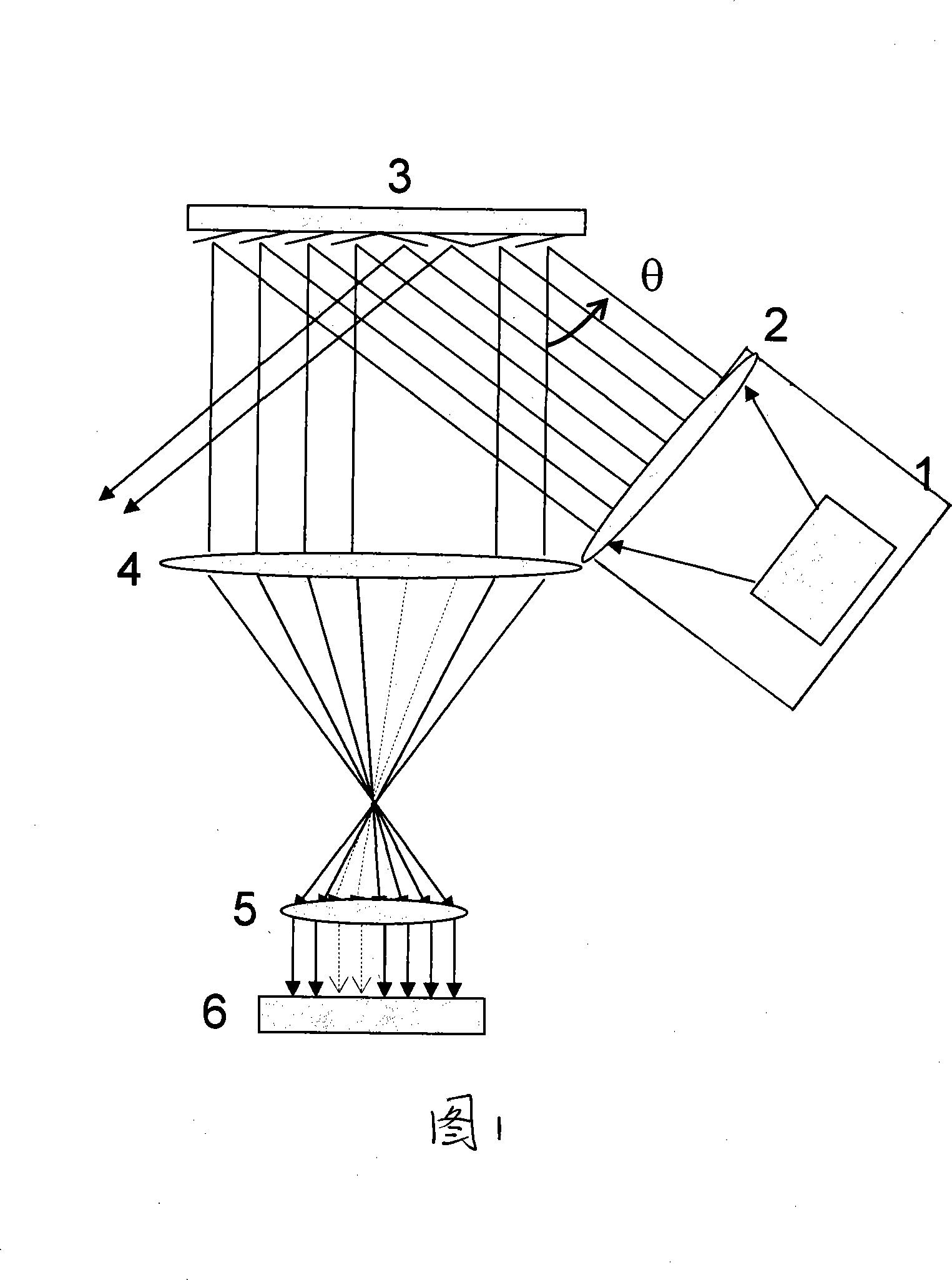

[0023] As shown in Figure 1, the light emitted by the illumination source 1 is converged and homogenized by the condenser lens system 2, and then incident on the spatial light modulator 3 at an angle of θ (the spatial light modulator in this figure is DMD as an example, and it can also be LCD and other light modulation devices), the incident light is imaged on the CCD6 through the telecentric imaging system 4 and 5 after being modulated by the spatial light modulator, so that the CCD can collect the light field intensity distribution of the image plane.

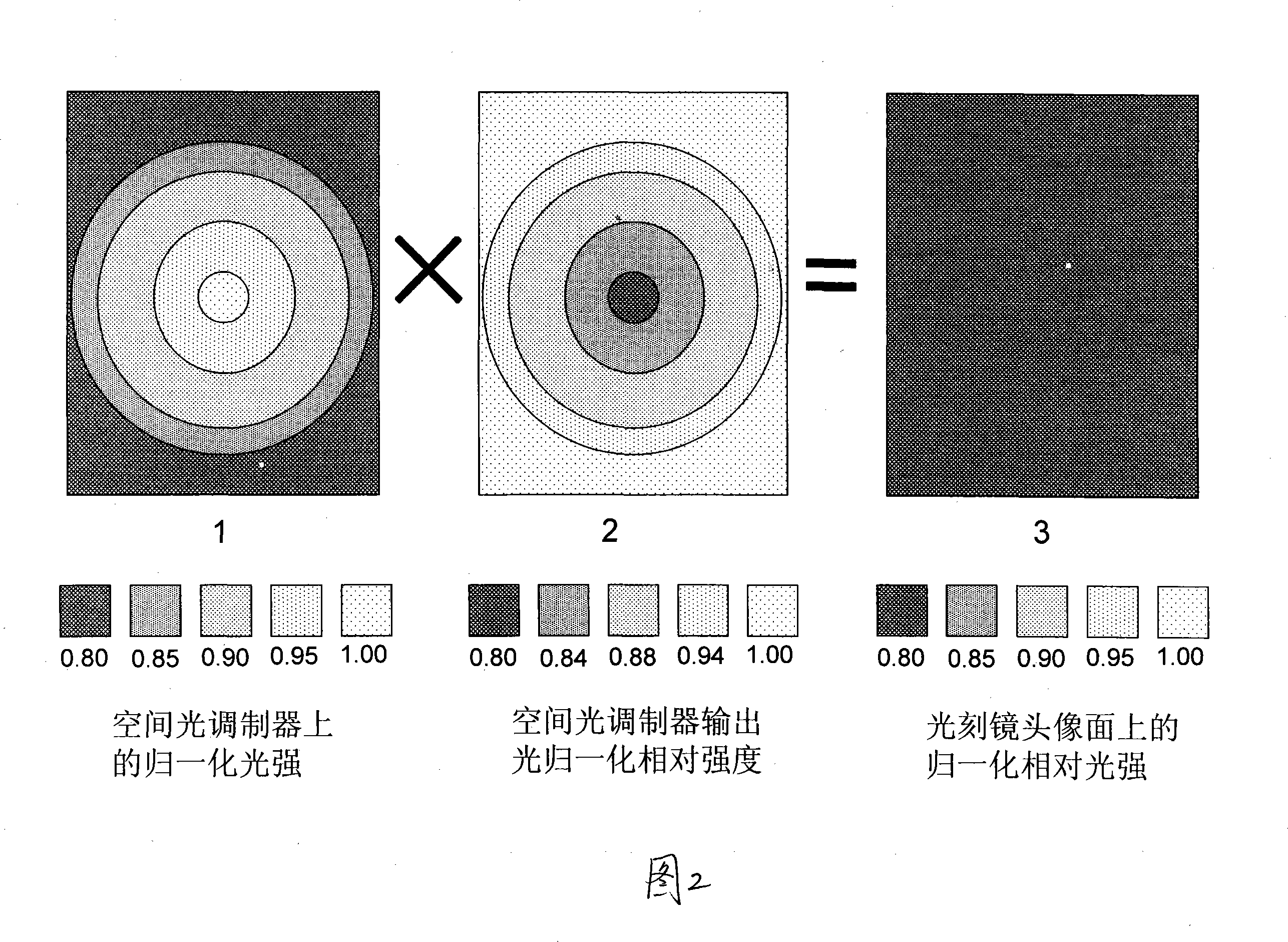

[0024] As shown in Figures 1 and 2, the concrete implementation steps of the present invention are as follows:

[0025] (1) The spatial light modulator 3 is placed in a fully open state, and the light emitted by the illumination source 1 is converged and homogenized by the condenser lens system and then irradiates the spatial light modulator 3 . The spatial light modulator 3 modulates the incident light and images it on the C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com