Tantalum ruthenium mixing type electrolytic capacitor and preparation method thereof

A technology of electrolytic capacitors and capacitors, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve problems such as increased internal resistance of the system, limitations of supercapacitors, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

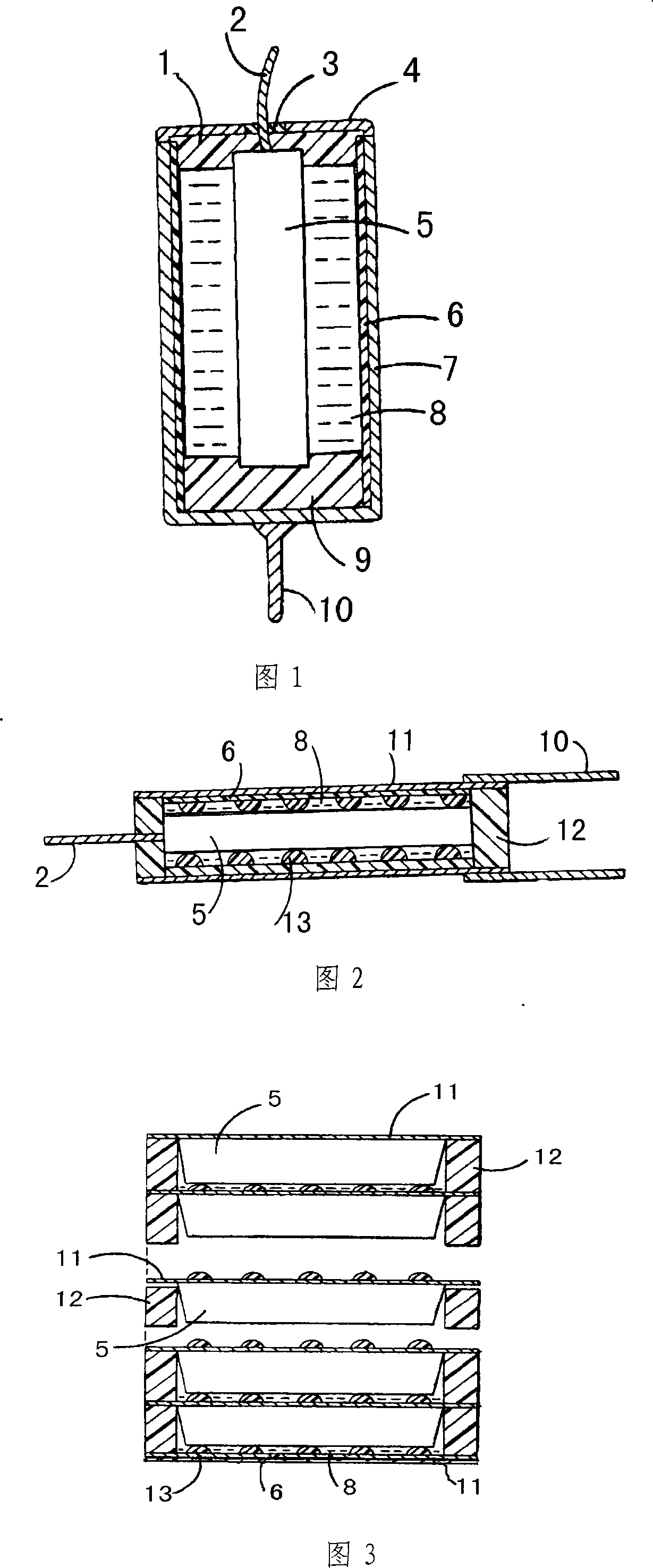

[0019] The invention provides a tantalum-ruthenium hybrid electrolytic capacitor and a preparation method thereof. The structure of the hybrid capacitor includes cylindrical, chip and chip series capacitor structures, and is composed of sintered tantalum anodes. The electrolyte and ruthenium oxide cathode are sealed in a tantalum shell, which is a tantalum-ruthenium hybrid electrolytic capacitor that combines the characteristics of a tantalum electrolytic capacitor and a ruthenium oxide supercapacitor.

[0020] Figure 1 shows a schematic diagram of the structure of a cylindrical hybrid capacitor. In the figure, the inner wall of the tantalum casing 7 is close to the ruthenium oxide cathode 6, and the sintered tantalum anode 5 is supported by the upper gasket 1 and the lower gasket 9 in the center of the ruthenium oxide cathode 6, between the ruthenium oxide cathode 6 and the sintered tantalum anode 5 The electrolyte 8 is filled, the anode lug 2 is insulated by the sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com