Solid biomass upright continuous retorting device

A solid biomass, dry distillation technology, used in special forms of dry distillation, biofuels, petroleum industry and other directions, can solve problems such as difficulty in solving high-yield and high-quality, indirect dry distillation technology can not increase production, long dry distillation retention period and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

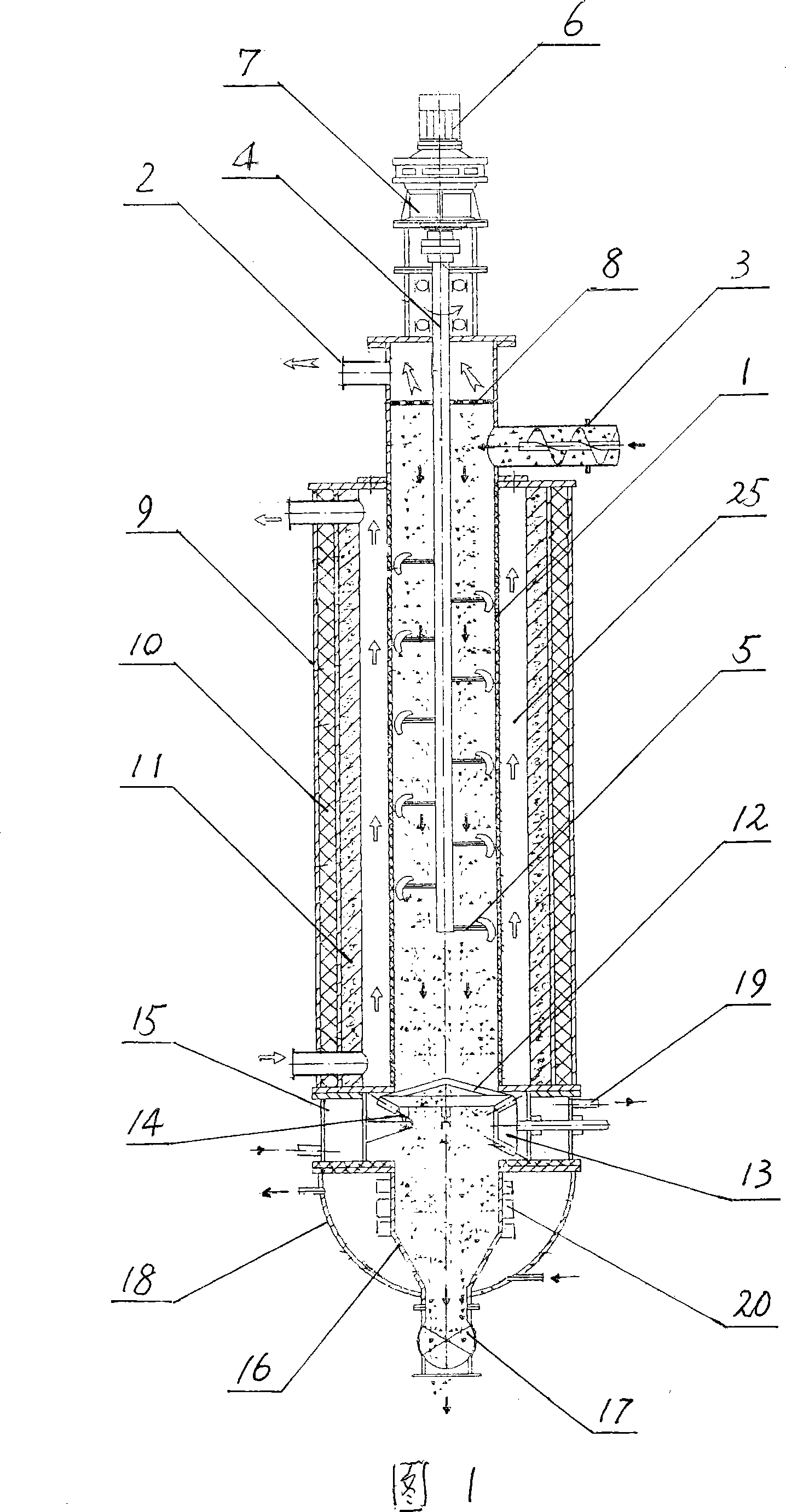

[0013] 1. Process the shell 9, the cooling chamber 15 with the water cooling jacket 19, the feed bin 16 and the cooling water tank 18 with steel plates. An insulating layer 10 and a refractory layer 11 are laid on the inner wall of the casing 9 . There is at least one gas inlet at the bottom of the housing 9 and a gas outlet at the top, and the inlet and outlet are not on the same busbar to avoid gas short circuit.

[0014] 2. Process the retort cylinder 1 with the retort gas outlet 2 with ceramics, fit and fix the retort cylinder 1 coaxially with the housing 9 , and form a heating chamber 25 between the retort cylinder 1 and the refractory layer 11 . A motor 6 and a reducer 7 are arranged on the top of the retort cylinder 1 , and cooperate with the agitator inside the retort cylinder 1 , and a grille 8 is arranged inside the retort cylinder 1 . A screw feeder 3 is provided at the upper end of the dry distillation cylinder 1 .

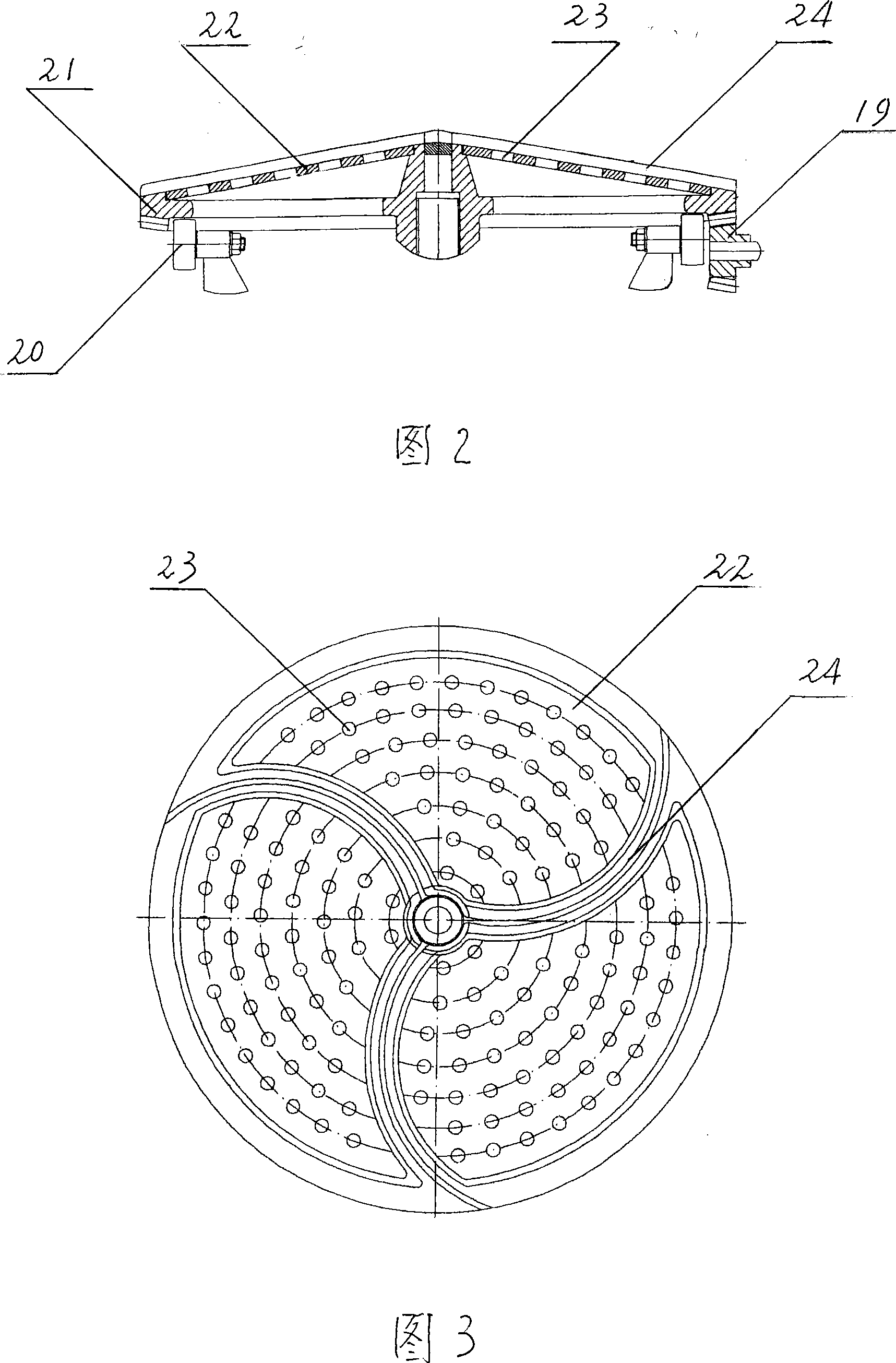

[0015] 3. The rotary table 12 is cast as a who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com