Flywheel energy-accumulating type secondary regulation flux coupling system

A technology of secondary adjustment and flywheel energy storage, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the problems of high system cost, high power density, low energy density, etc., and achieve reduction Cost, reduced installed power, and small effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

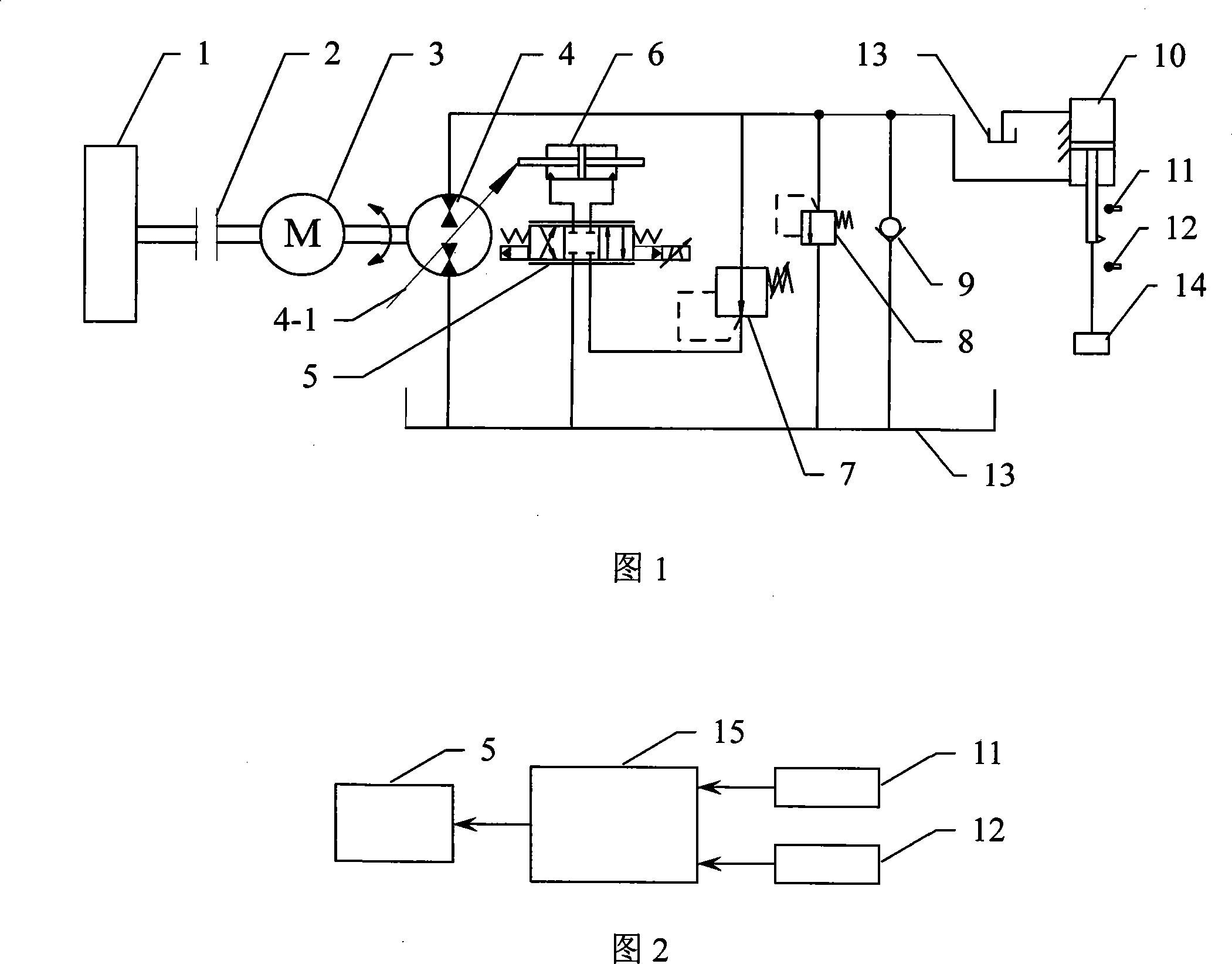

[0010] Specific Embodiment 1: The flywheel energy storage type secondary adjustment flow coupling system of this embodiment consists of a biaxial motor 3, a hydraulic pump / motor 4, an electro-hydraulic control valve 5, a variable cylinder 6, a pressure reducing valve 7, and a hydraulic cylinder 10 , an upper limit sensor 11, a lower limit sensor 12, a fuel tank 13, a controller 15 and a flywheel 1; the drive shaft of the flywheel 1 is fixedly connected to an output shaft of the biaxial motor 3, and the other output shaft of the biaxial motor It is fixedly connected with the transmission shaft of the hydraulic pump / motor 4, the swash plate 4-1 of the hydraulic pump / motor 4 is connected with the piston rod of the variable cylinder 6, and the two oil delivery ports of the variable cylinder 6 are respectively connected with the electro-hydraulic control valve 5 The two oil delivery ports of the electro-hydraulic control valve 5 communicate with the oil outlet of the fuel tank 13 an...

specific Embodiment approach 2

[0016] Embodiment 2: The difference between this embodiment and the flywheel energy storage type secondary regulation flow coupling system described in Embodiment 1 is that it also includes an electromagnetic clutch 2, the drive shaft of the flywheel 1 and the output of the biaxial motor 3 The shafts are connected by electromagnetic clutch 2.

[0017] When the flywheel energy storage type secondary regulation flow coupling system described in this embodiment is working, the initial state of the system is: the hydraulic pump / motor 4 is in the pump mode, the electromagnetic clutch 2 is in the disengaged state, and the biaxial motor 3 is in the Working status, the working process is:

[0018] Driven by a motor, the double-axis motor 3 drives the hydraulic pump / motor 4 to drive the hydraulic cylinder 10 to drive the load 14 to rise;

[0019] Drive / energy storage conversion, when the hydraulic cylinder 10 drives the load 14 up to the position where the upper limit sensor 11 is tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com