Direct-touch type metal diaphragm valve

一种接触型、隔膜阀的技术,应用在隔膜阀、隔膜、阀细节等方向,能够解决流量增大等问题,达到形态稳定化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

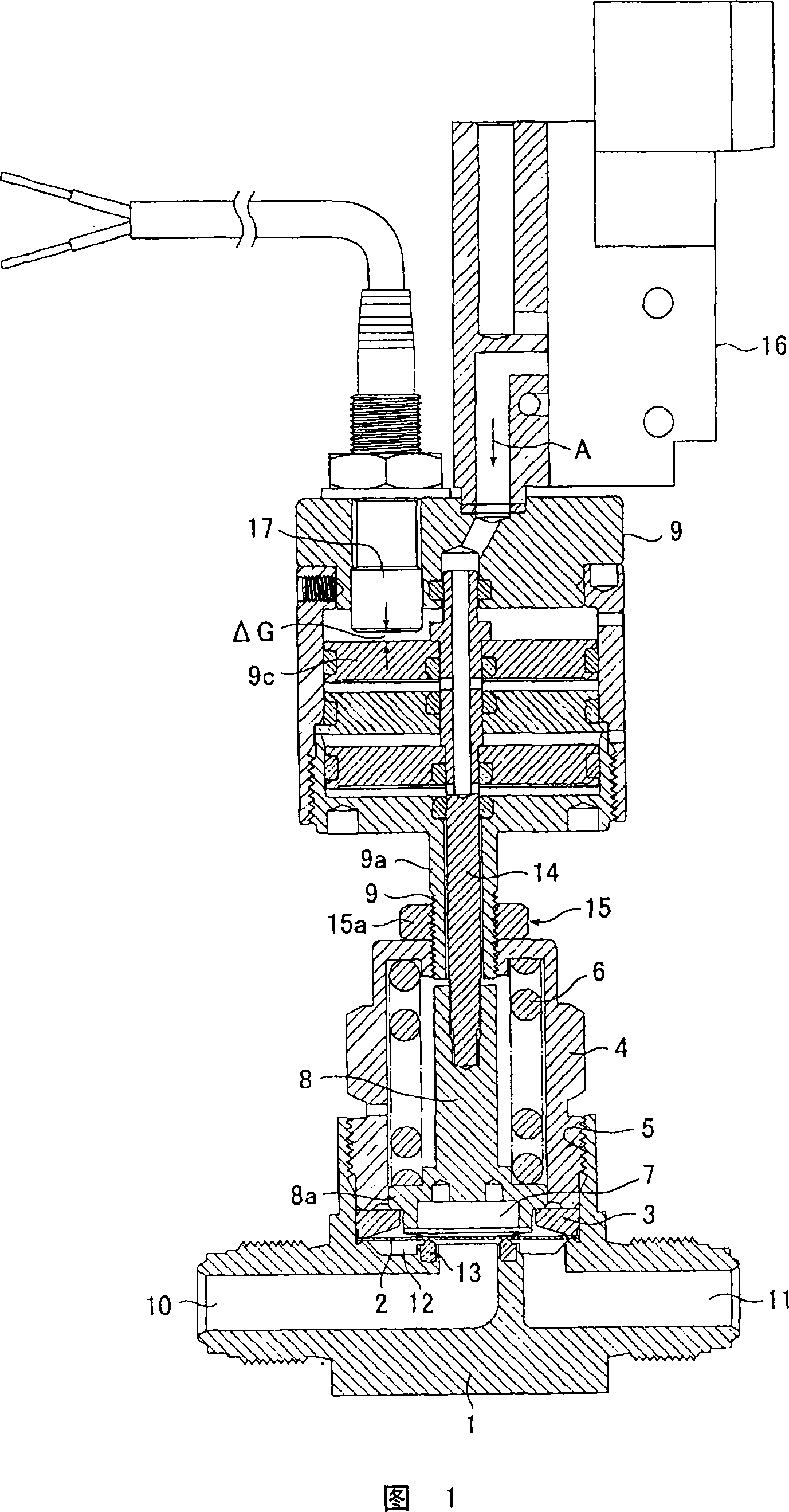

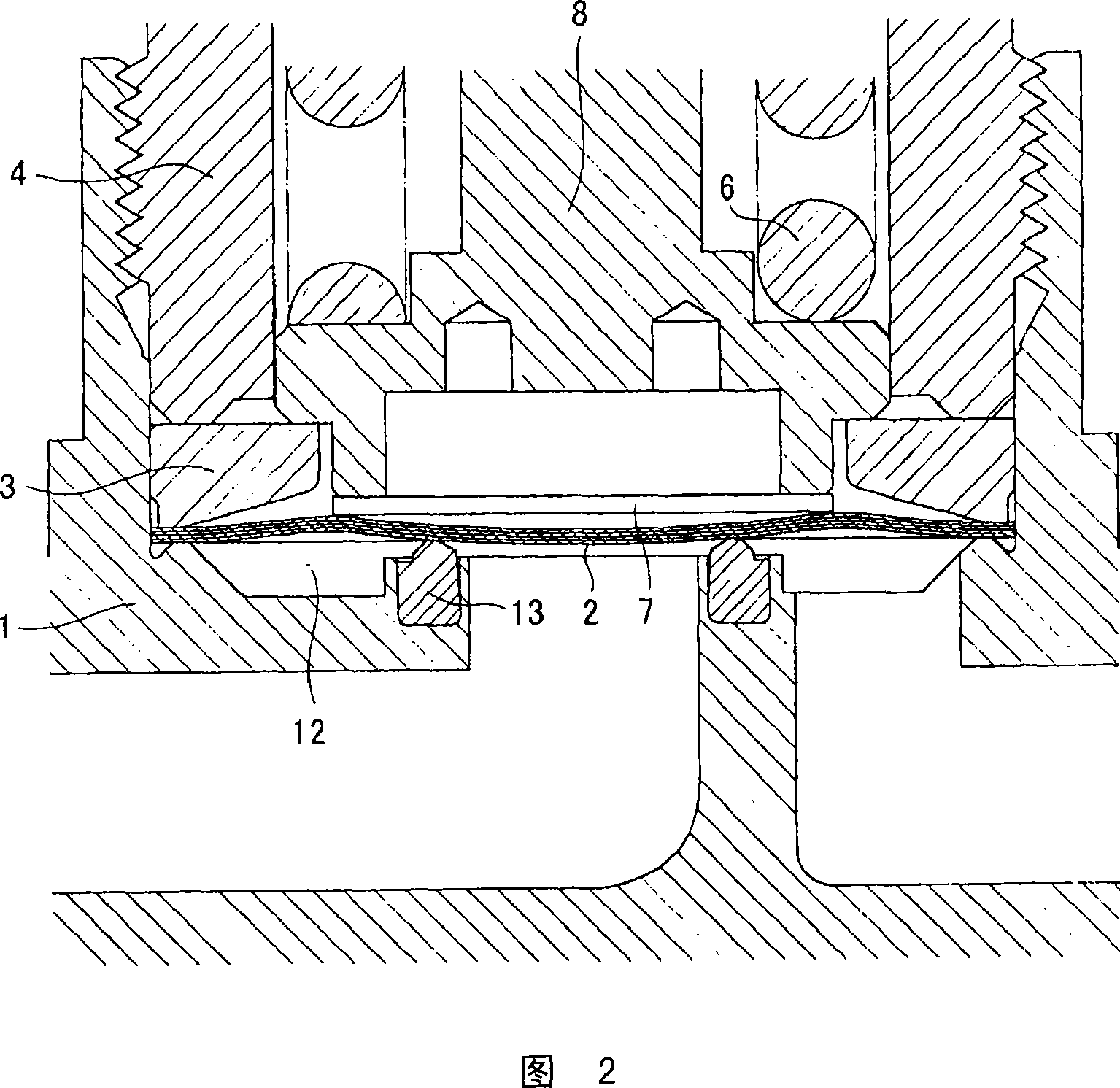

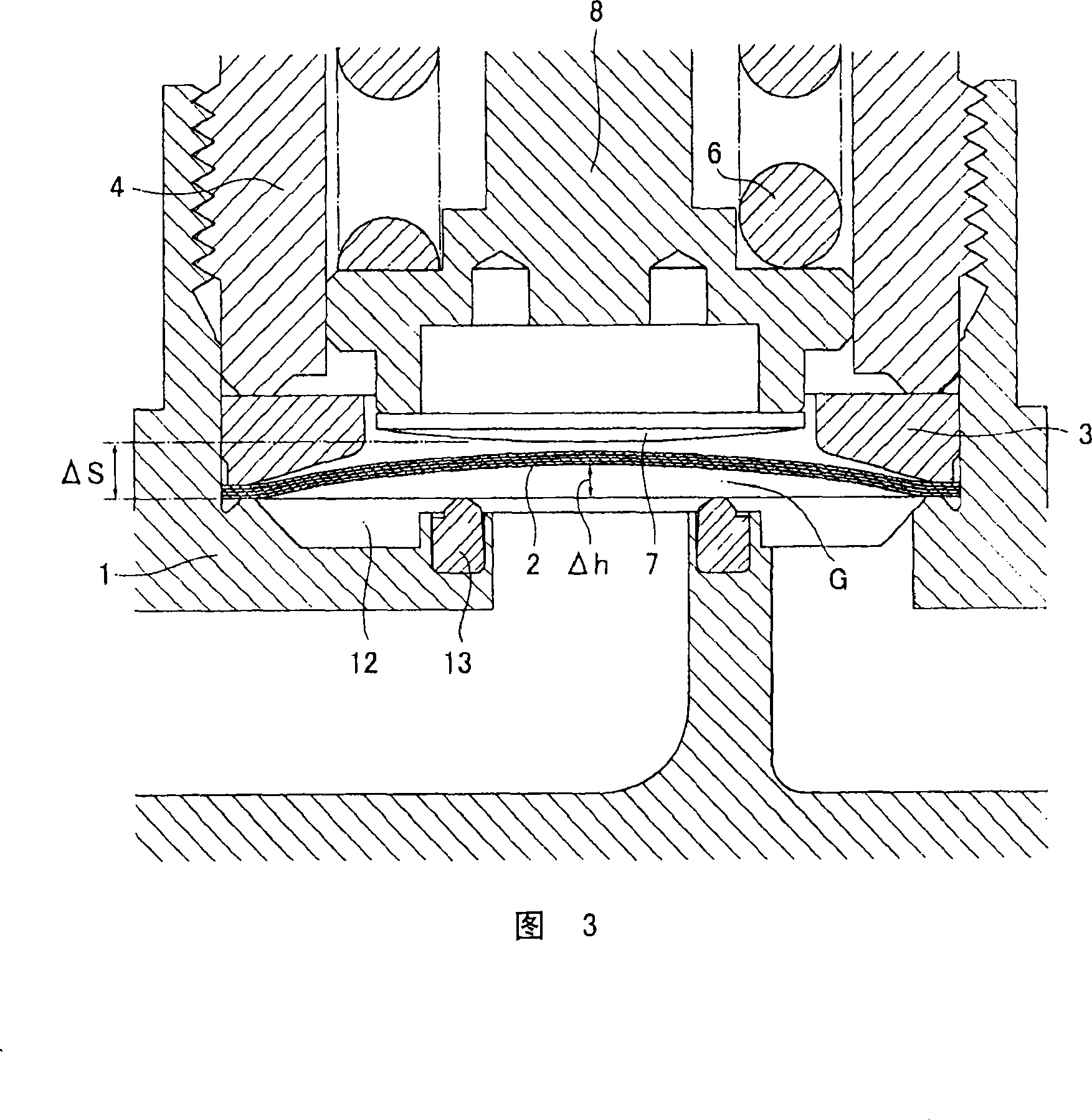

[0109] Referring to Fig. 2, Fig. 2 is a partially enlarged view showing the closed state of the valve using the metal diaphragm 2 of the above-mentioned embodiment 1, and Fig. 3 is a diagram showing the use of the metal diaphragm 2 of the embodiment 1 when the valve stroke ΔS is 1.5mm. Partial enlarged view of the valve opening state.

[0110] In Fig. 2 and Fig. 3, the valve stroke ΔS is selected as 1.5mm, and the valve stroke ΔS is larger than the maximum bulge height Δh=1.2mm of the metal diaphragm 2, so the metal diaphragm 2 is completely restored to its original state.

specific example 2

[0112] On the other hand, Fig. 4 and Fig. 5 show the closed state ( Fig. 4 ) and the valve open state when the valve stroke ΔS is set to 0.7 mm in the valve of Fig. 1 using the metal diaphragm 2 of the first embodiment described above. (FIG. 5) A partially enlarged view of the state. When the valve is closed, the metal diaphragm 2 does not return to the complete original state as shown in FIG. 3, but becomes a somewhat deformed state.

[0113] That is, when the valve stroke ΔS is reduced, the amount of deformation of the metal diaphragm 2 becomes smaller, and the deformation stress acting on the metal diaphragm 2 becomes relatively smaller.

[0114] In the case of the valve stroke ΔS=1.5mm and ΔS=0.7mm, there is a large difference in the form of the metal diaphragm 2 as described above, but the distance between the valve seat 3 and the inner surface of the metal diaphragm 2 can be judged. Gap G did not change much.

specific example 3

[0116] 6 and 7 show that the metal diaphragm valve of FIG. 1 using the metal diaphragm 2 of the above-mentioned embodiment 1 is used to measure the flow rate using the Cv value measurement test device of the above-mentioned FIG. 8, and the Cv value is obtained by using the above-mentioned (2) formula In addition, Table 1 is a list of the above-mentioned lift and flow and Cv values.

[0117] Among them, the test was carried out under the conditions of an operating air pressure of 0.55 MPa and a protrusion height of the valve seat of 0.128 mm (height after baking at 80°C).

[0118] 【Table 1】

[0119] Lift(mm)

[0120] It can be seen from FIG. 6 and FIG. 7 that the valve stroke ΔS=about 0.65-0.8, and the Cv value=0.55-0.6 required by the valve can be realized. That is, it is preferable to realize a Cv value of 0.6 by setting the valve stroke ΔS=0.7 mm, and it can be seen that the metal diaphragm 2 does not need to be deformed to the maximum until the valve stroke reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com