Microwave rotating thin film concentrator

A technology of rotating thin film and concentrator, which is applied in forced circulation evaporators, chemical instruments and methods, lighting and heating equipment, etc., to achieve the effects of reducing volume, convenient and thorough cleaning, and increasing evaporation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

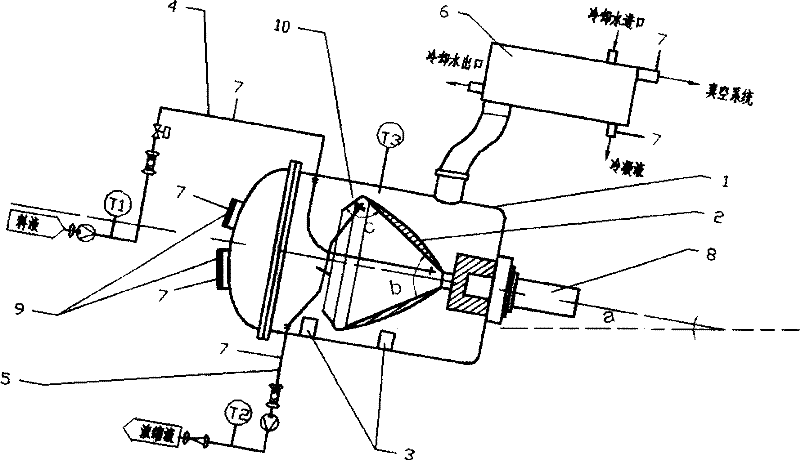

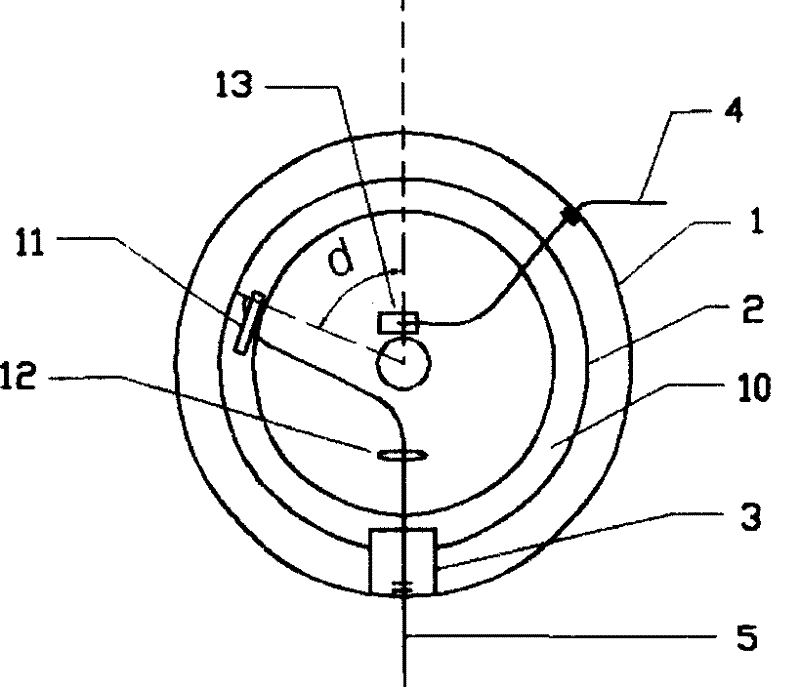

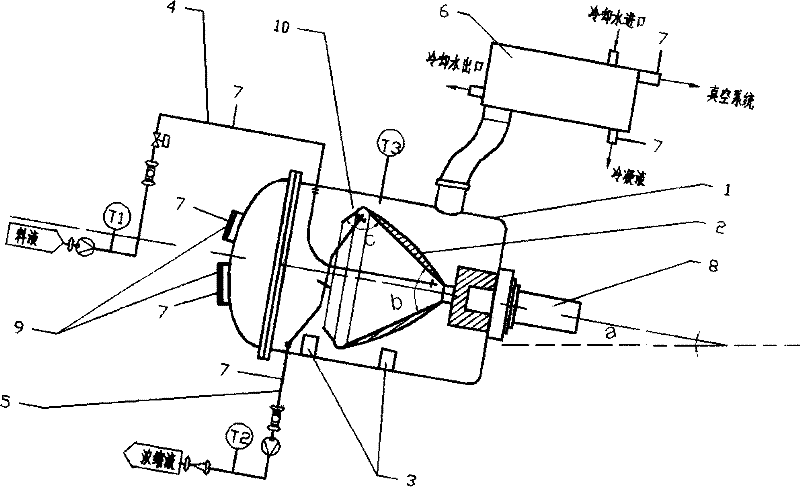

[0017] Microwave rotary thin film concentrator, including airtight tank 1, rotary evaporator 2, microwave generator 3, solution feed pipe 4, concentrate liquid discharge pipe 5, condenser 6, microwave shielding device 7, stirring motor 8 and vacuum system.

[0018] The main body of the microwave rotary thin film concentrator is a closed tank body, which is a cylindrical cavity with an openable cover, a sight glass on the cover, and a microwave shielding device on the inner surface of the observation window; a microwave device is placed in the closed tank At the inner wall; the tank body has an opening, and the opening is connected to the condenser, and the condenser is connected to the vacuum system through a pipeline. A rotating thin-film concentrator is placed in the center of the tank. The evaporation surface of the evaporator is designed in a conical shape. The evaporator cone angle b is 180°; the angle a between the axis of the evaporator and the horizontal plane is 90°. ...

Embodiment 2

[0020] Microwave rotary thin film concentrator, including airtight tank 1, rotary evaporator 2, microwave generator 3, solution feed pipe 4, concentrate liquid discharge pipe 5, condenser 6, microwave shielding device 7, stirring motor 8 and vacuum system.

[0021] The main body of the microwave rotary thin film concentrator is a closed tank body, which is a cylindrical cavity with an openable cover, a sight glass on the cover, and a microwave shielding device on the inner surface of the observation window; the microwave device is placed on the inner wall of the closed tank There are 2 places; the tank body has an opening, and the opening is connected to the condenser, and the condenser is connected to the vacuum system through a pipeline. A rotating thin-film concentrator is placed in the center of the tank. The evaporation surface of the evaporator is designed in a conical shape. The evaporator cone angle b is 60°; the angle a between the axis of the evaporator and the horiz...

Embodiment 3

[0023] Microwave rotary thin film concentrator, including airtight tank 1, rotary evaporator 2, microwave generator 3, solution feed pipe 4, concentrate liquid discharge pipe 5, condenser 6, microwave shielding device 7, stirring motor 8 and vacuum system.

[0024] The main body of the microwave rotary thin-film concentrator is a closed tank body, which is a cylindrical cavity with an openable cover. There are 2 sight glasses on the cover, and there is a microwave shielding device on the inner surface of the observation window; a microwave device is placed in the The solution feed pipe outside the closed tank body; the tank body has an opening, which is connected to the condenser, and the condenser is connected to the vacuum system through a pipeline. A rotating thin-film concentrator is placed in the center of the tank. The evaporation surface of the evaporator is designed in a conical shape. The evaporator cone angle b is 120°; the angle a between the axis of the evaporator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com