Zirconium-base amorphous-crystal multiple phase material and preparation method thereof

A zirconium-based amorphous and crystalline technology, which is applied in the field of zirconium-based amorphous-crystalline composite materials, can solve the problems of macroscopic plastic deformation and easy sudden brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

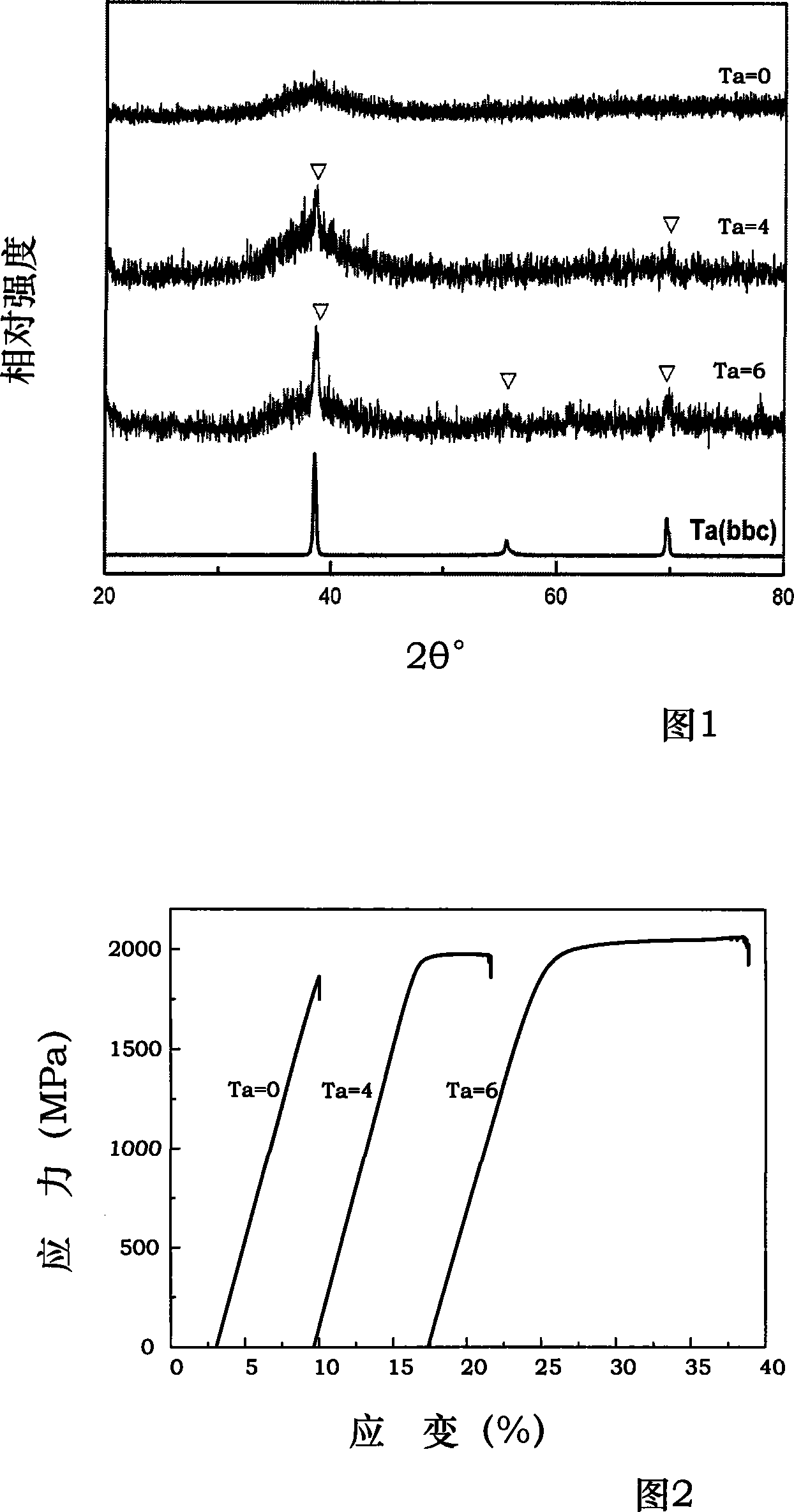

[0024] Example 1: Zr 46 Cu 36 Al 10 Dy 2 Ta 6

[0025] The first step: with the target ingredients

[0026] High-purity (purity greater than 99%) Zr, Cu, Al, Dy, Ta are prepared according to the atomic percentage of the nominal composition.

[0027] The second step: Vacuum melting Zr-Cu-Al-Dy-Ta alloy

[0028] (A) Put the Zr and Ta raw materials weighed in the first step into a vacuum arc melting furnace, and vacuumize to 5×10 -3 Pa, then filled with high-purity argon to 0.4×10 5 Pa, then smelt Zr-Ta alloy at 3100°C;

[0029] (B) Put the Cu, Al, Dy raw materials and Zr-Ta alloy weighed in the first step into a vacuum arc melting furnace, and vacuumize to 5×10 -3 Pa, filled with high-purity argon to 0.4×10 5 Pa, and then smelted at 2500 ° C to make Zr-Cu-Al-Dy-Ta alloy;

[0030] The third step: metal mold casting Zr 46 Cu 36 Al 10 Dy 2 Ta 6 Material

[0031] Put the Zr-Cu-Al-Dy-Ta alloy prepared in the second step into the quartz tube of the rapid solidificati...

Embodiment 2

[0034] Example 2: Zr 48 Cu 36 al 10 Gd 2 Ta 4

[0035] The first step: with the target ingredients

[0036] High-purity (purity greater than 99%) Zr, Cu, Al, Gd, Ta are prepared according to the atomic percentage of the nominal composition.

[0037] The second step: Vacuum melting Zr-Cu-Al-Gd-Ta alloy

[0038] (A) Put the Zr and Ta raw materials weighed in the first step into a vacuum arc melting furnace, and vacuumize to 5×10 -3 Pa, then filled with high-purity argon to 0.4×10 5 Pa, then smelt Zr-Ta alloy at 3100°C;

[0039] (B) Put the Cu, Al, Gd raw materials and Zr-Ta alloy weighed in the first step into a vacuum arc melting furnace, and vacuumize to 5×10 -3 Pa, filled with high-purity argon to 0.4×10 5 Pa, and then smelted at 2200 ° C to make Zr-Cu-Al-Gd-Ta alloy;

[0040] The third step: metal mold casting Zr 48 Cu 36 al 10 Gd 2 Ta 4 Material

[0041] Put the Zr-Cu-Al-Gd-Ta alloy prepared in the second step into the quartz tube of the rapid solidificat...

Embodiment 3

[0043] Example 3: Zr 46 Cu 36 al 10 Er 2 Ta 6

[0044] The first step: with the target ingredients

[0045] High-purity (purity greater than 99%) Zr, Cu, Al, Er, Ta are prepared according to the atomic percentage of the nominal composition.

[0046] The second step: Vacuum melting Zr-Cu-Al-Er-Ta alloy

[0047] (A) Put the Zr and Ta raw materials weighed in the first step into a vacuum arc melting furnace, and vacuumize to 5×10 -3 Pa, then filled with high-purity argon to 0.4×10 5 Pa, then smelt Zr-Ta alloy at 3300°C;

[0048] (B) Put the Cu, Al, Er raw materials and Zr-Ta alloy weighed in the first step into a vacuum arc melting furnace, and vacuumize to 5×10 -3 Pa, filled with high-purity argon to 0.4×10 5 Pa, and then smelted at 2200 ° C to make Zr-Cu-Al-Er-Ta alloy;

[0049] The third step: metal mold casting Zr 46 Cu 36 al 10 Er 2 Ta 6 Material

[0050] Put the Zr-Cu-Al-Er-Ta alloy prepared in the second step into the quartz tube of the rapid solidificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com