Composition of environmental protection plastic products and manufacturing method

A technology of environmentally friendly plastics and manufacturing methods, applied in the field of plastic products, can solve the problems of raw material consumption, long operation time, waste, etc., and achieve the effects of reducing plastic usage, cost reduction, and good mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with accompanying drawing, preferred embodiment of the present invention is described in detail as follows:

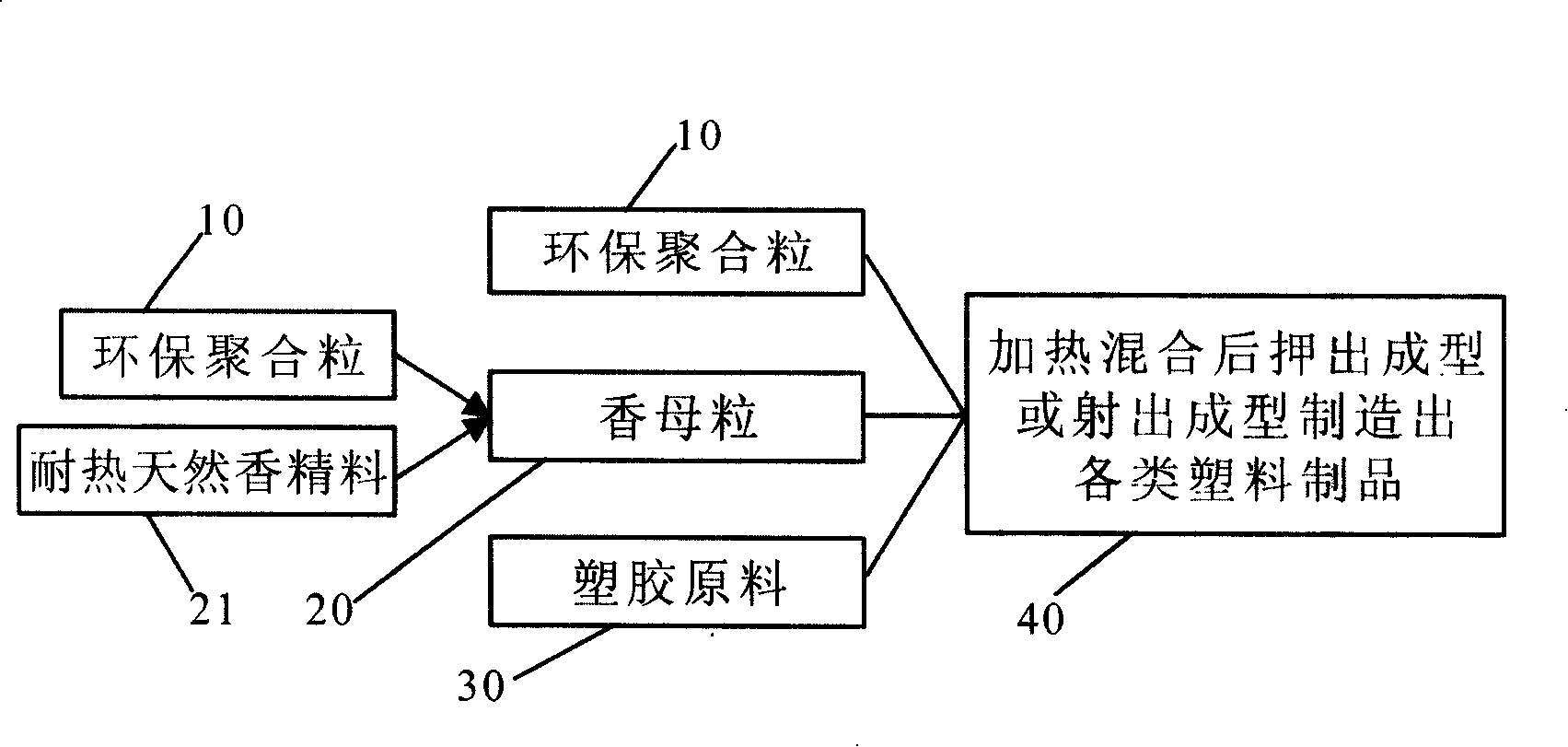

[0031] Please refer to figure 1 and figure 2 , is a block diagram of the composition and manufacturing process of an environmentally friendly plastic product of the present invention. The composition of the environment-friendly plastic product of the present invention mainly comprises: 1-50% of environment-friendly polymer particles 10, 1-50% of fragrant masterbatch 20 and 20-80% of plastic raw materials 30, which are formed by heating and kneading. The weight percentages of the above-mentioned components are mainly determined according to the characteristics of the environmentally friendly plastic products to be manufactured and molded. in,

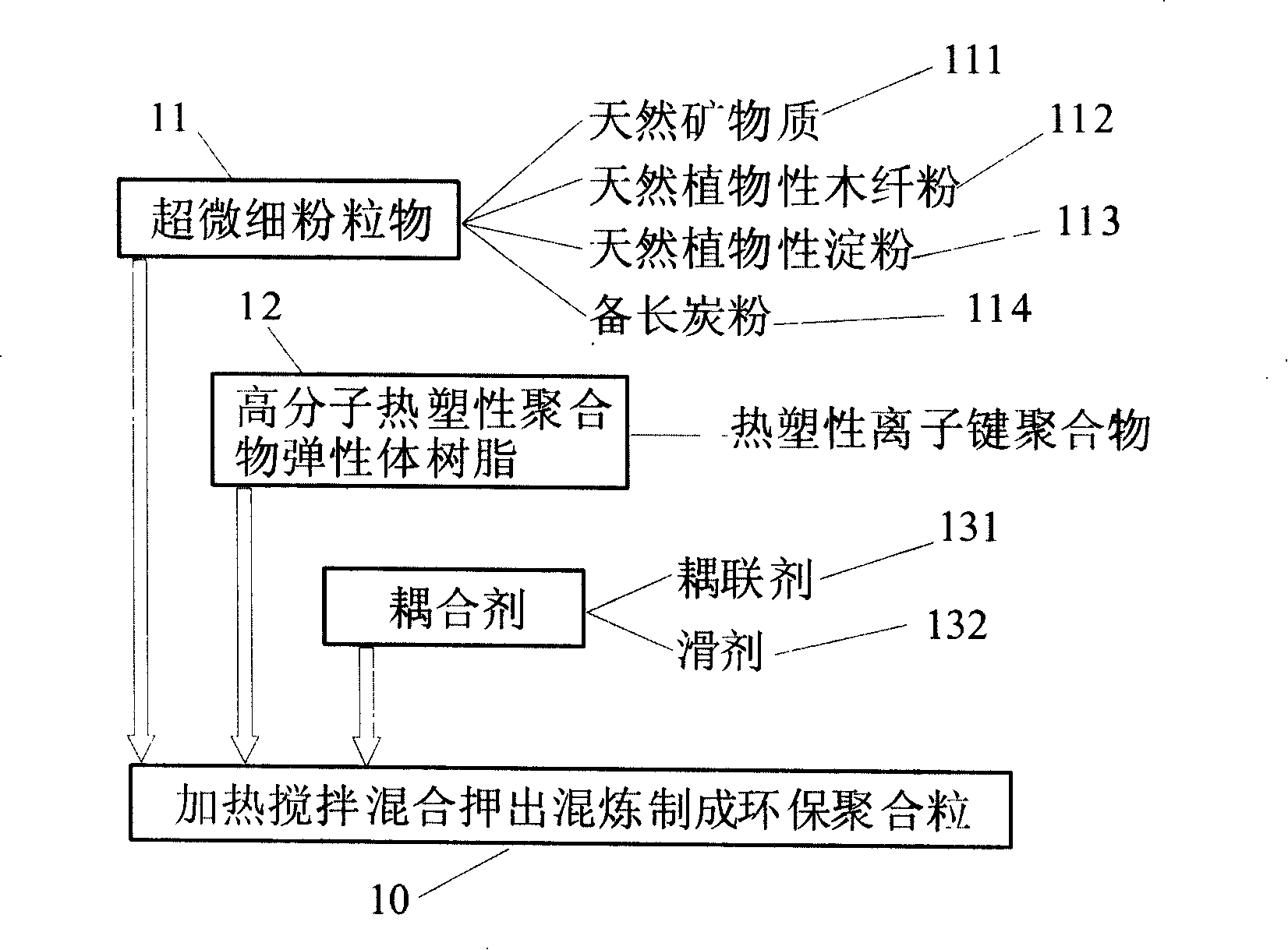

[0032] The composition of the environment-friendly polymer particles 10 includes particles made of several ultrafine powder particles 11 , high molecular thermoplastic polymer elastomer resin 12 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com