Single-component high peel strength epoxy resin adhesive and preparation method thereof

An epoxy resin and adhesive technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of long storage time, difficult to achieve curing time, etc., to improve performance, take into account storage stability, improve curing Effects of speed and degree of cure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

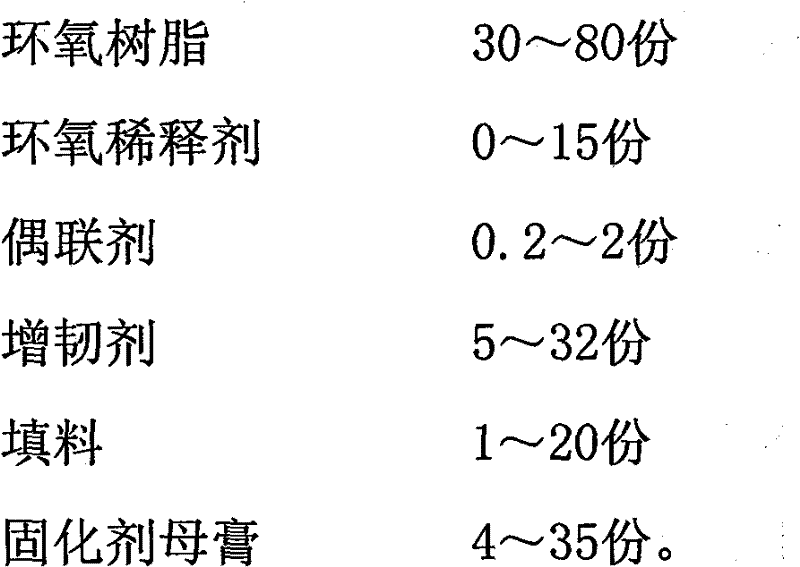

[0057] The one-component high peel strength epoxy resin adhesive includes the following formula by weight:

[0058] Epoxy resin A: 20 parts of polyurethane modified epoxy resin

[0059] Epoxy resin B: 30 parts of bisphenol F epoxy resin

[0060] Toughening agent: 10 parts of liquid carboxylated nitrile rubber

[0061] Thinner: Lauryl Glycidyl Ether 13 parts

[0062] Coupling agent: 1 part of γ-epoxypropoxytriethoxysilane

[0063] Filler: Fumed white carbon black 1 part

[0064] Curing agent master paste 25 parts

[0065] Wherein, curing agent mother paste comprises following formula by weight part:

[0066] Epoxy resin: bisphenol F epoxy resin 64 parts

[0067] Stabilizer: 1 part fumaric acid

[0068] Latent curing agent: imidazole latent curing agent (Asahi Denka EH-4232)

[0069] 35 copies

[0070] The preparation method of single-component high peel strength epoxy resin adhesive comprises the steps:

[0071] (1) Pre-prepared cu...

Embodiment 2

[0077] The one-component high peel strength epoxy resin adhesive includes the following formula by weight:

[0078] Epoxy resin A: CTBN modified epoxy resin 15 parts

[0079] Epoxy resin B: 30 parts of bisphenol F epoxy resin

[0080] Toughener: shell / core polymer (Rohm and Haas EXL-2655)

[0081] 20 copies

[0082] Coupling agent: 1 part of γ-epoxypropoxytriethoxysilane

[0083] Filler A: Fumed white carbon black 1 part

[0084] Filler B: 18 parts of light calcium carbonate

[0085] Curing agent master paste 15 parts

[0086] The formula of curing agent mother paste is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com