Method and system for wafer inspection

A technology of wafers and inspectors, which is applied in the direction of originals for photomechanical processing, photolithography of patterned surfaces, image data processing, etc., can solve the problems of time-consuming, expensive masks, etc. when the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

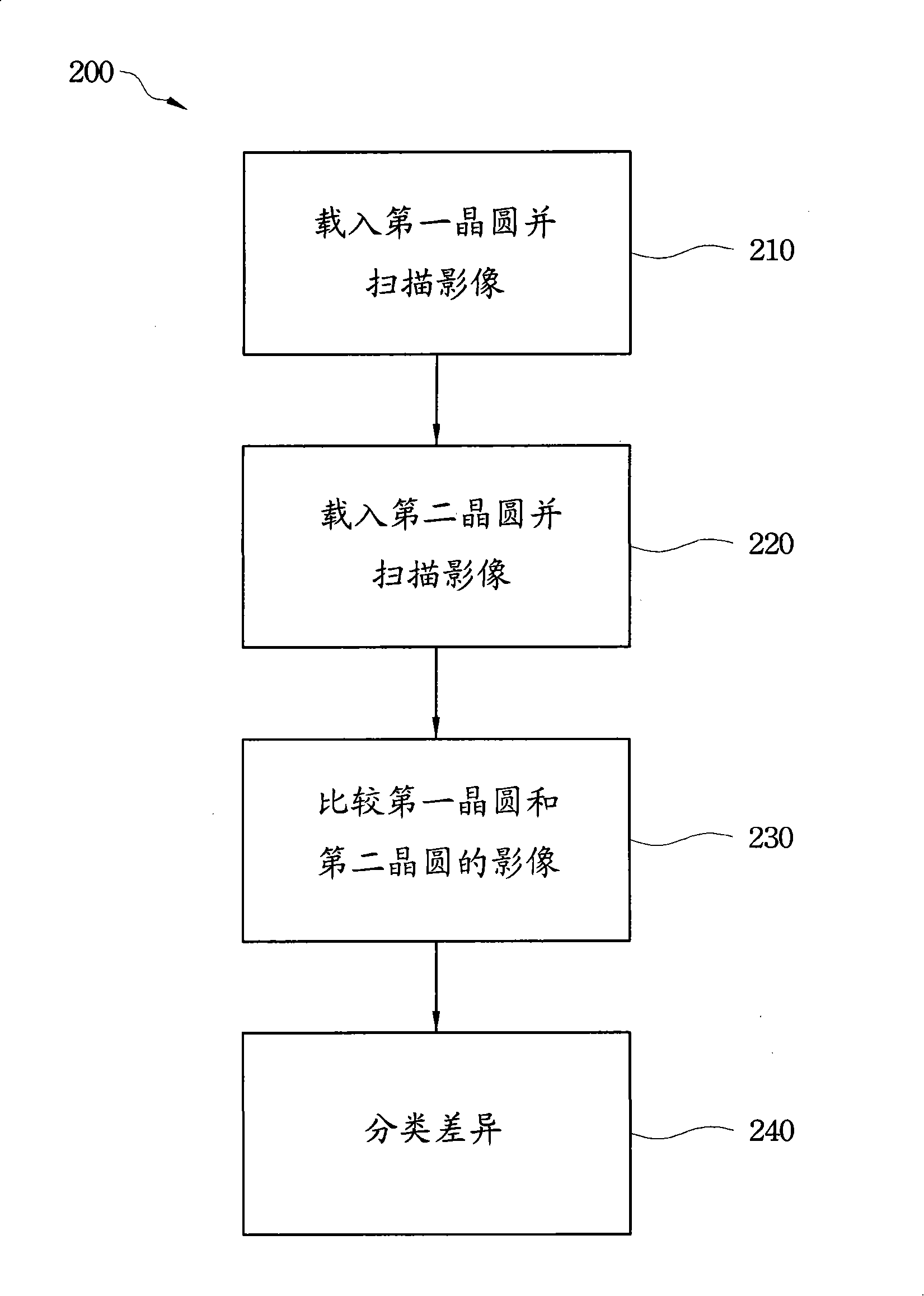

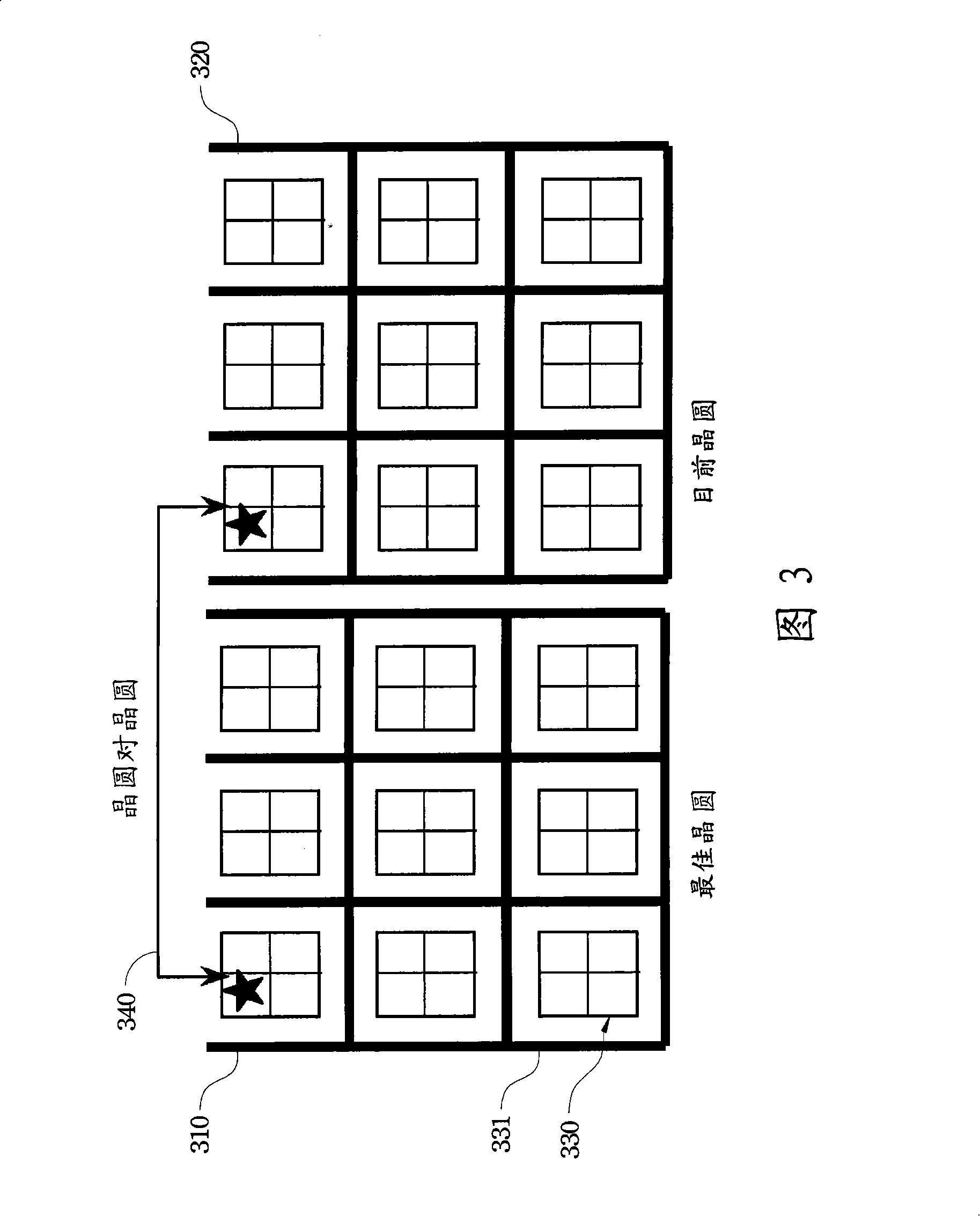

[0062] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation methods, methods and steps of the wafer inspection method and system proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , structure, feature and effect thereof, detailed description is as follows.

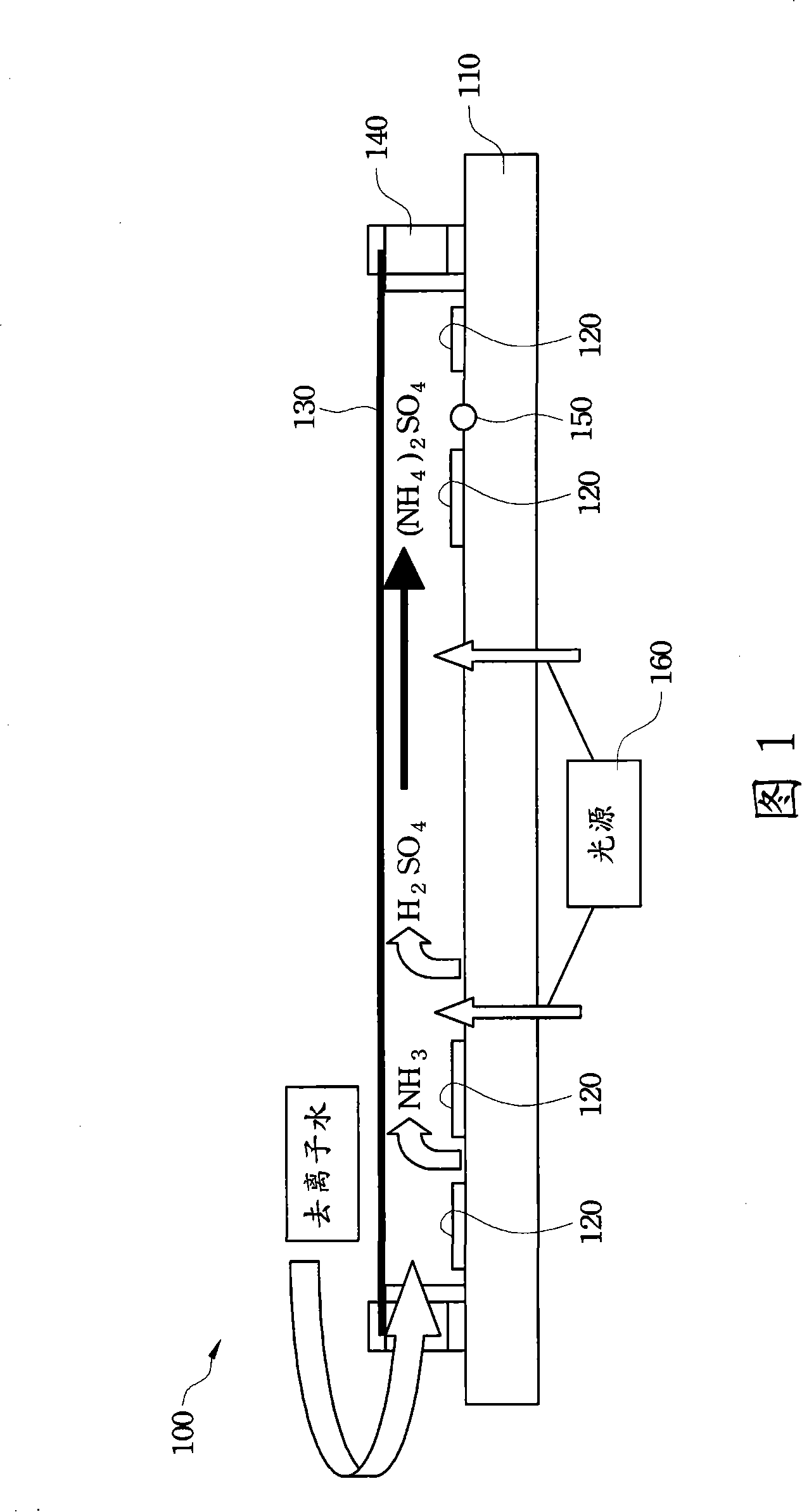

[0063] Please refer to FIG. 1 , which shows a photomask 100 with deposits such as haze contamination. In semiconductor manufacturing, the photomask 100 is used in a lithography process to transfer an image of a circuit pattern onto a semiconductor wafer. The photomask 100 can include a transparent substrate 110, and the transparent substrate 110 has fused quartz (Fused Quartz), calcium fluoride (CaF 2 ), or other suitable materials. The photomask 100 may further include an absorbing layer 120 formed on the transparent substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com