High speed X light strong conveyer band detection system

A technology for detection systems and conveyor belts, applied in the direction of measuring devices, instruments, and wave/particle radiation, can solve the problems of slow scanning speed, poor implementation, and inaccurate positioning, so as to improve scanning speed and facilitate The effect of remote transmission and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail

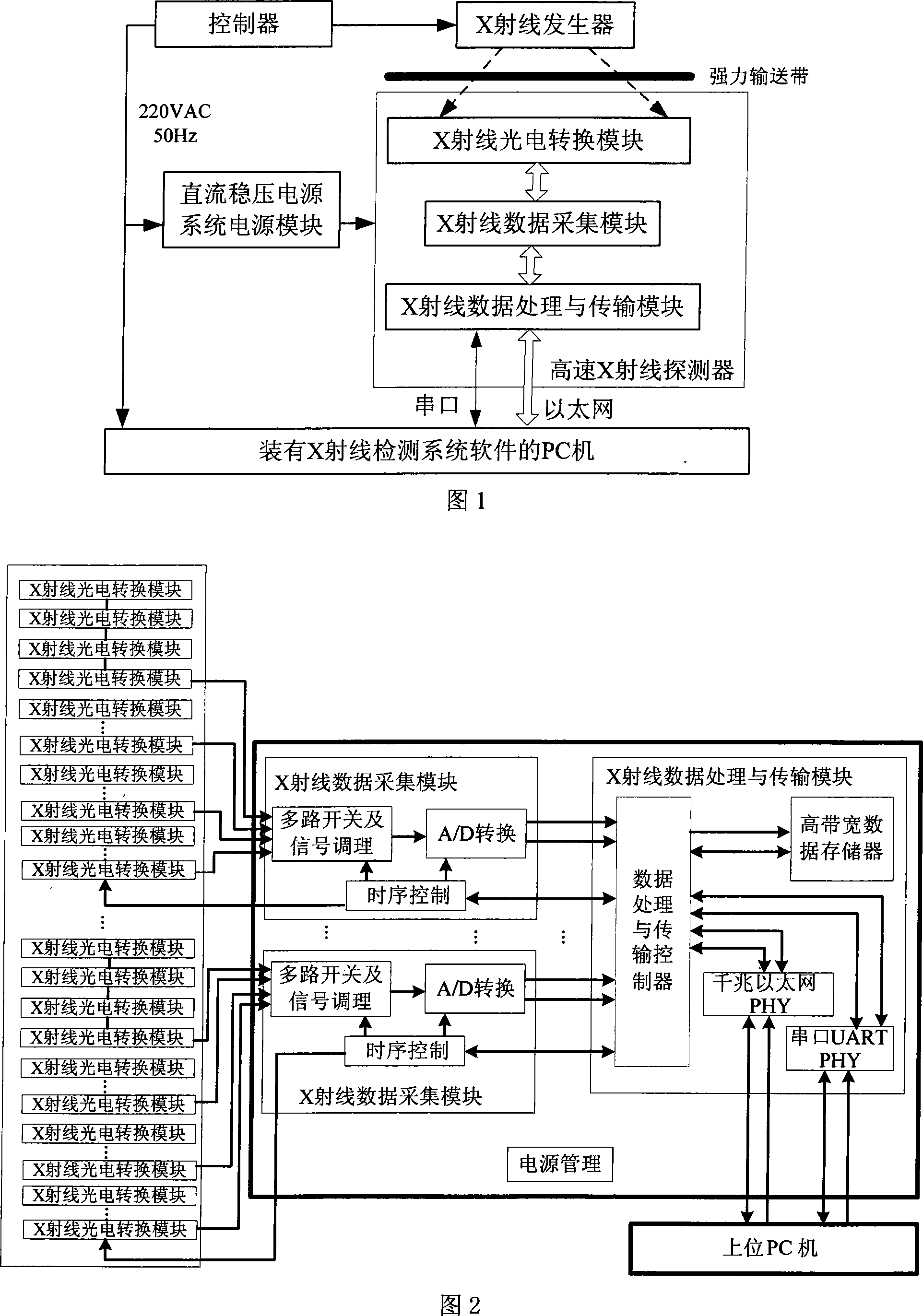

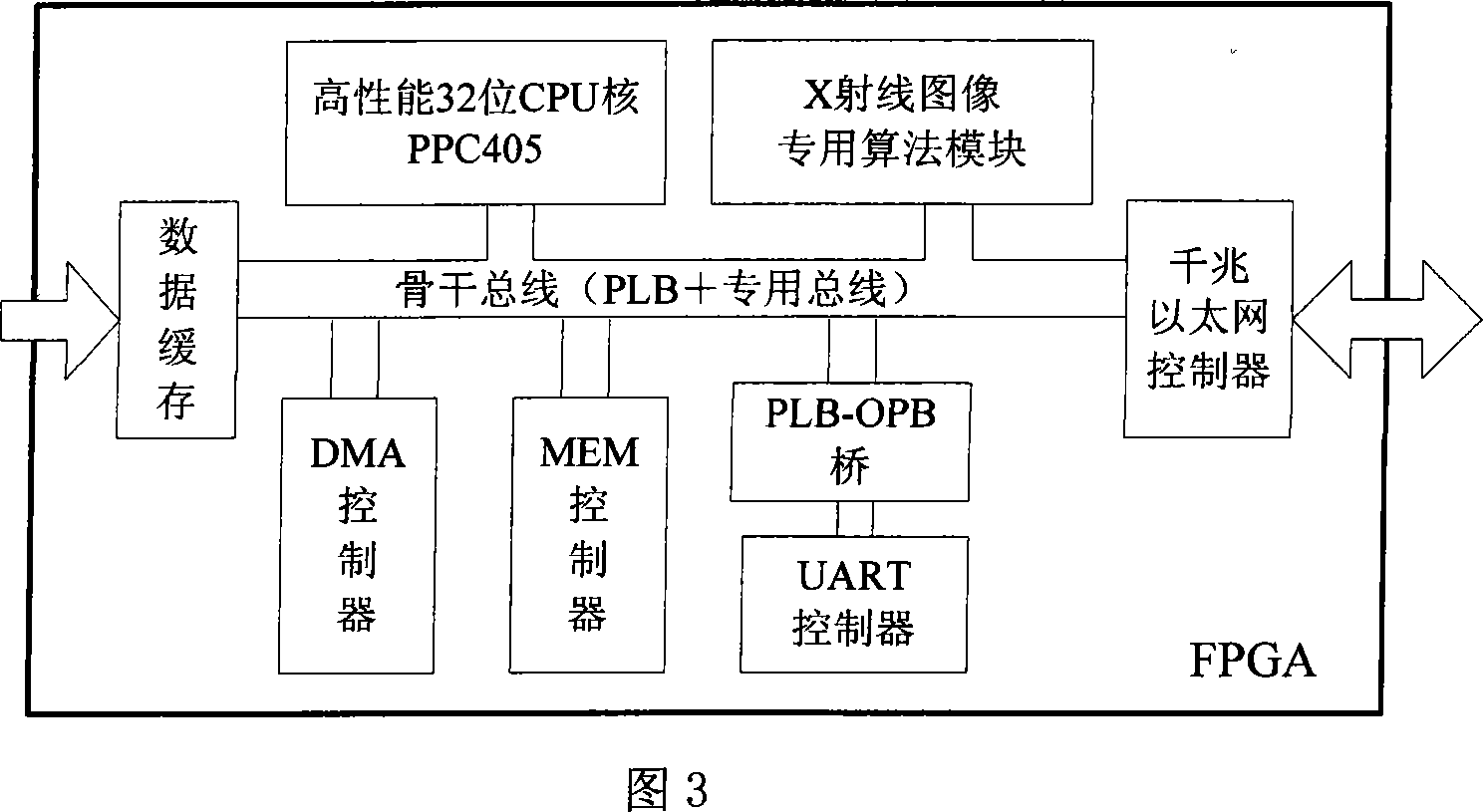

[0021] Fig. 1 is a structural block diagram of the high-speed X-ray powerful conveyor belt detection system of the present invention. The high-speed X-ray powerful conveyor belt detection system of the present invention is composed of an X-ray generator and its controller, a high-speed X-ray detector, a system power supply module and a PC equipped with X-ray detection system software. The high-speed X-ray detector includes an X-ray photoelectric conversion module, an X-ray data acquisition module, and an X-ray data processing and transmission module.

[0022] The X-rays generated by the X-ray generator pass through the running powerful conveyor belt and irradiate to the high-speed X-ray detector. High-speed X-ray detectors are used to receive, process and transmit X-rays passing through powerful conveyor belts. First, the one-dimensional array of silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com