Deep sea optic cable and its manufacture method

An optical cable and deep-sea technology, applied in the field of deep-sea optical cable and its production, can solve the problems that the life of the optical cable cannot be effectively guaranteed, the structure is not reasonable and reliable, etc., and achieve the effect of superior performance, compact structure, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

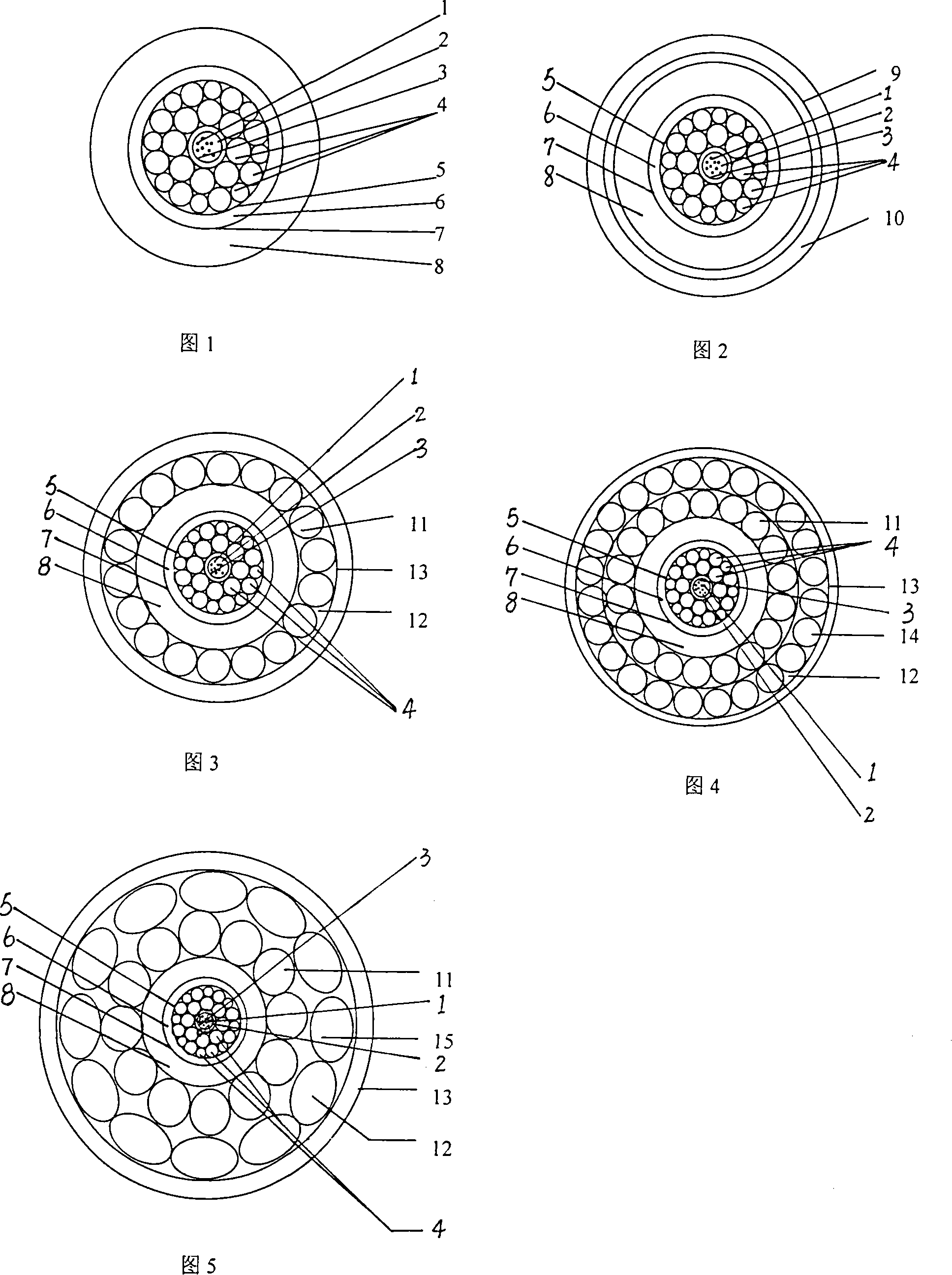

[0039] Referring to attached drawings 1 to 5, the deep-sea optical cable includes several full-chromatographic high-strength optical fibers 1, high-strength corrosion-resistant stainless steel tube 2, special ointment for submarine cable optical fiber 3, three types of ultra-high-strength armored steel wires with unequal diameters 4, high-viscosity Water blocking agent 5, metal conductor copper tube 6, organic plastic composite material 7, polyethylene insulating material protective layer 8. A number of full-chromatographic high-strength optical fibers 1 are covered with high-strength corrosion-resistant stainless steel tubes 2. The high-strength corrosion-resistant stainless steel tubes 2 are filled with special ointment 3 for submarine cable optical fibers. The high-strength corrosion-resistant stainless steel tubes Three kinds of unequal-diameter armored steel wires 4 are filled with a sufficient amount of high-viscosity water-blocking agent 5 in the armored three kinds of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com