Solar battery chip protection structure

A solar cell and protective structure technology, applied in the field of solar energy, can solve the problems of reducing the fill factor, affecting the efficiency and life of the battery, and increasing the cost, so as to achieve the effects of increasing the fill factor, improving the effective utilization rate, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

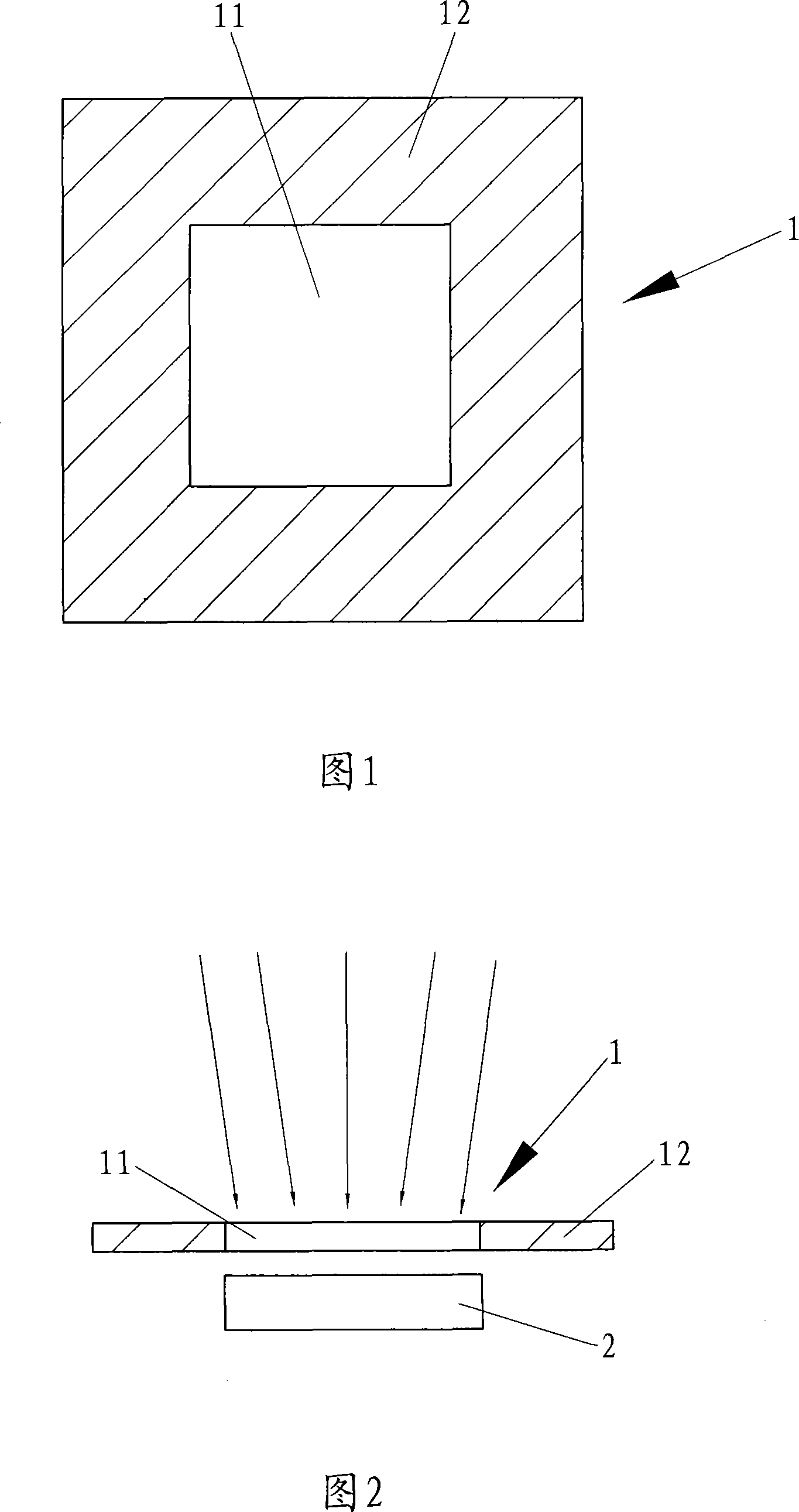

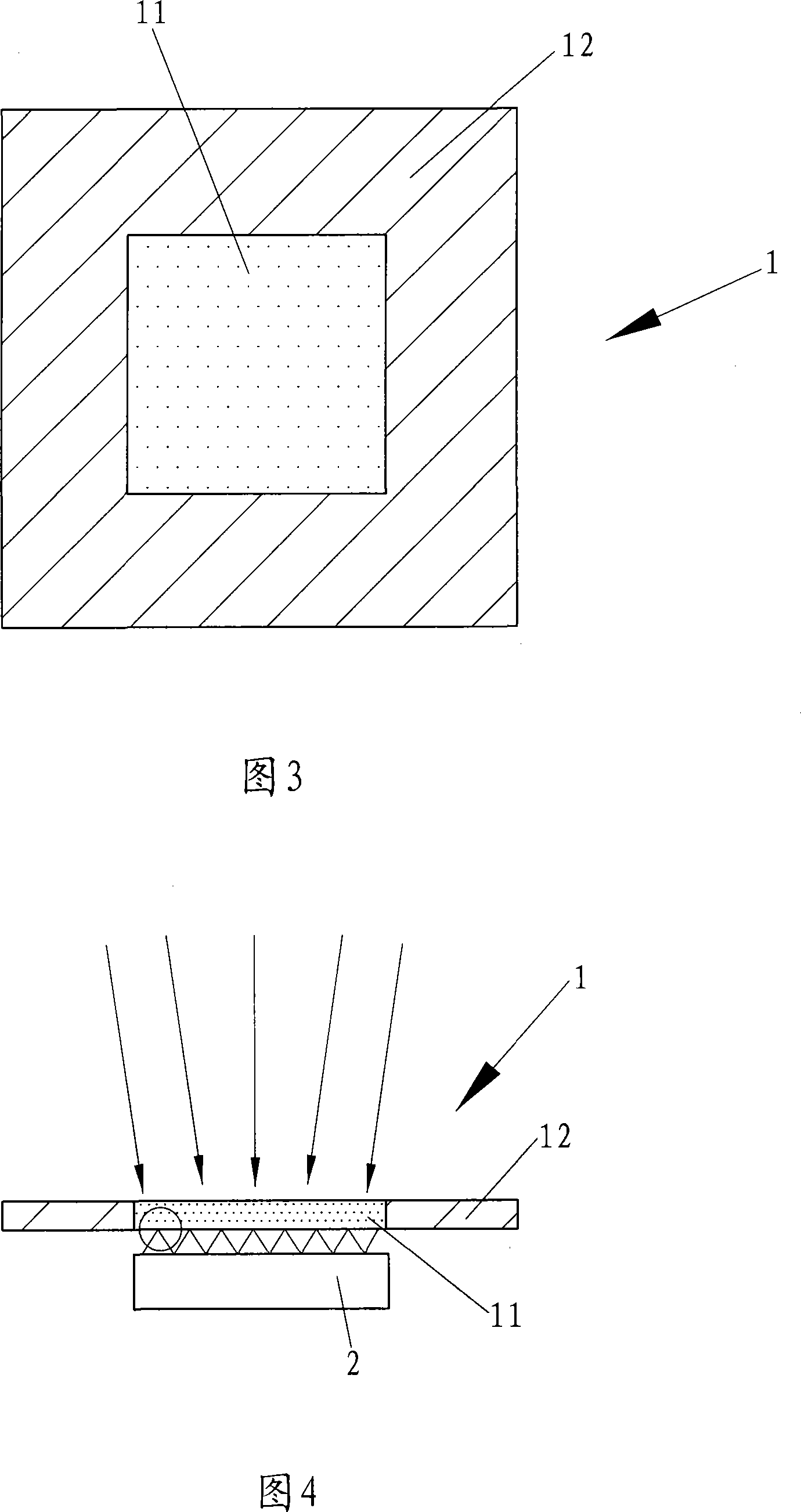

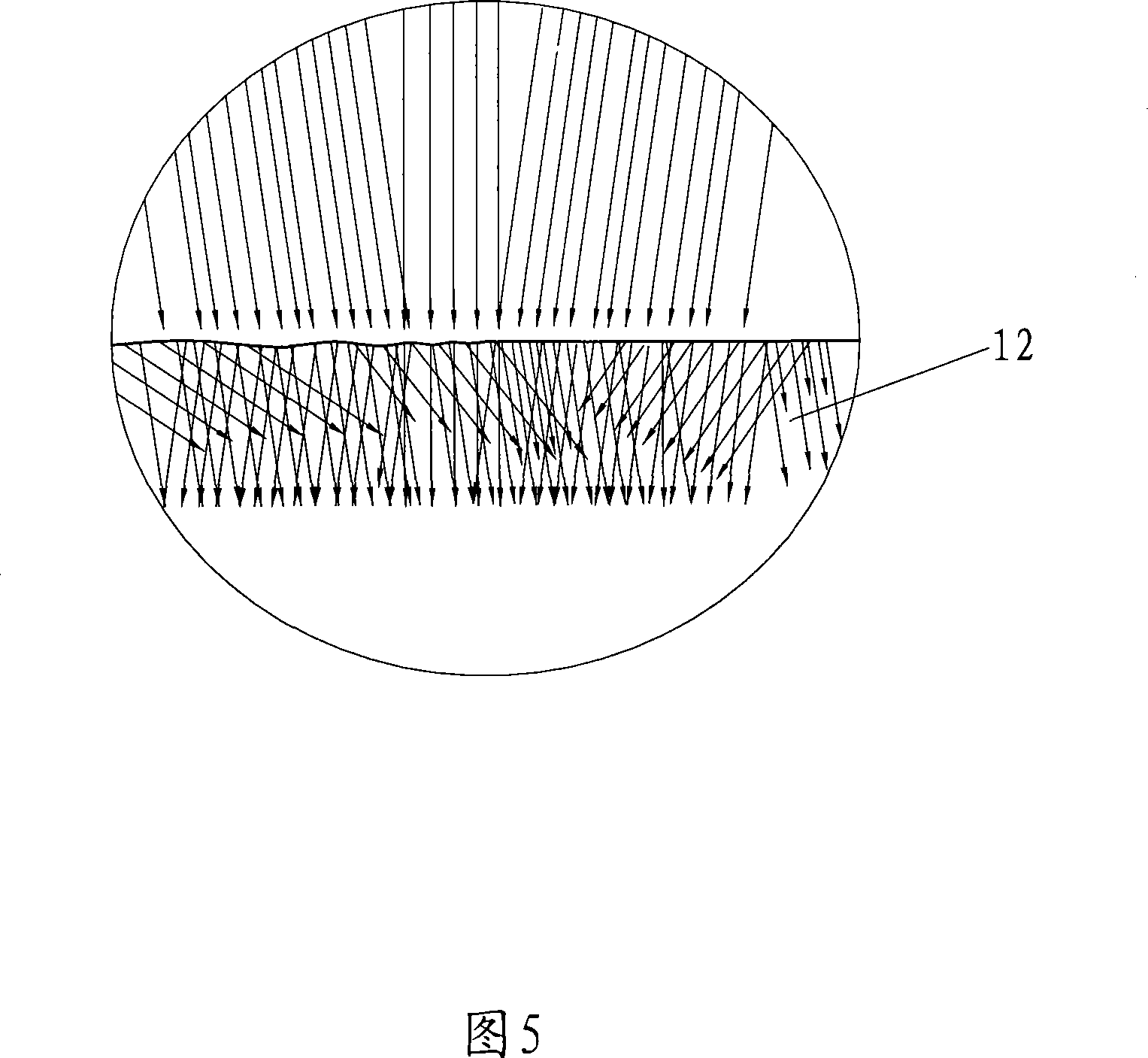

[0023] As shown in Figures 1 to 7, the solar cell chip protection structure of the present invention is provided with a concentrating mirror 1 on the upper part of the solar cell chip 2, wherein: the concentrating mirror 1 is provided with a light-transmitting area 11 at a position corresponding to the size of the cell chip 2, On the outer edge of the light-transmitting area 11 of the condenser 1 is a light-reflecting area 12 .

[0024] The size of the light-transmitting area 11 just corresponds to the size of the battery chip 2, so the battery chip 2 can effectively collect sunlight; in addition, the unused concentrated light outside the solar chip 2 is reflected or absorbed by the light-reflecting area 12 so as not to irradiate the PCB board , causing the temperature rise to melt or crack the PCB board, thereby effectively prolonging the service life of the solar cell.

[0025] As shown in Fig. 1, 2 is embodiment 1 of the present invention, and this concentrating mirror 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com