Non-stirring oxidization device of flue gas desulfurization slurry pool

A desulfurization slurry and oxidation device technology, which is applied to chemical instruments and methods, separation methods, and dispersed particle separation, can solve problems such as easy failures and complex structures, and achieve the effect of improving desulfurization efficiency and eliminating the need for stirring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

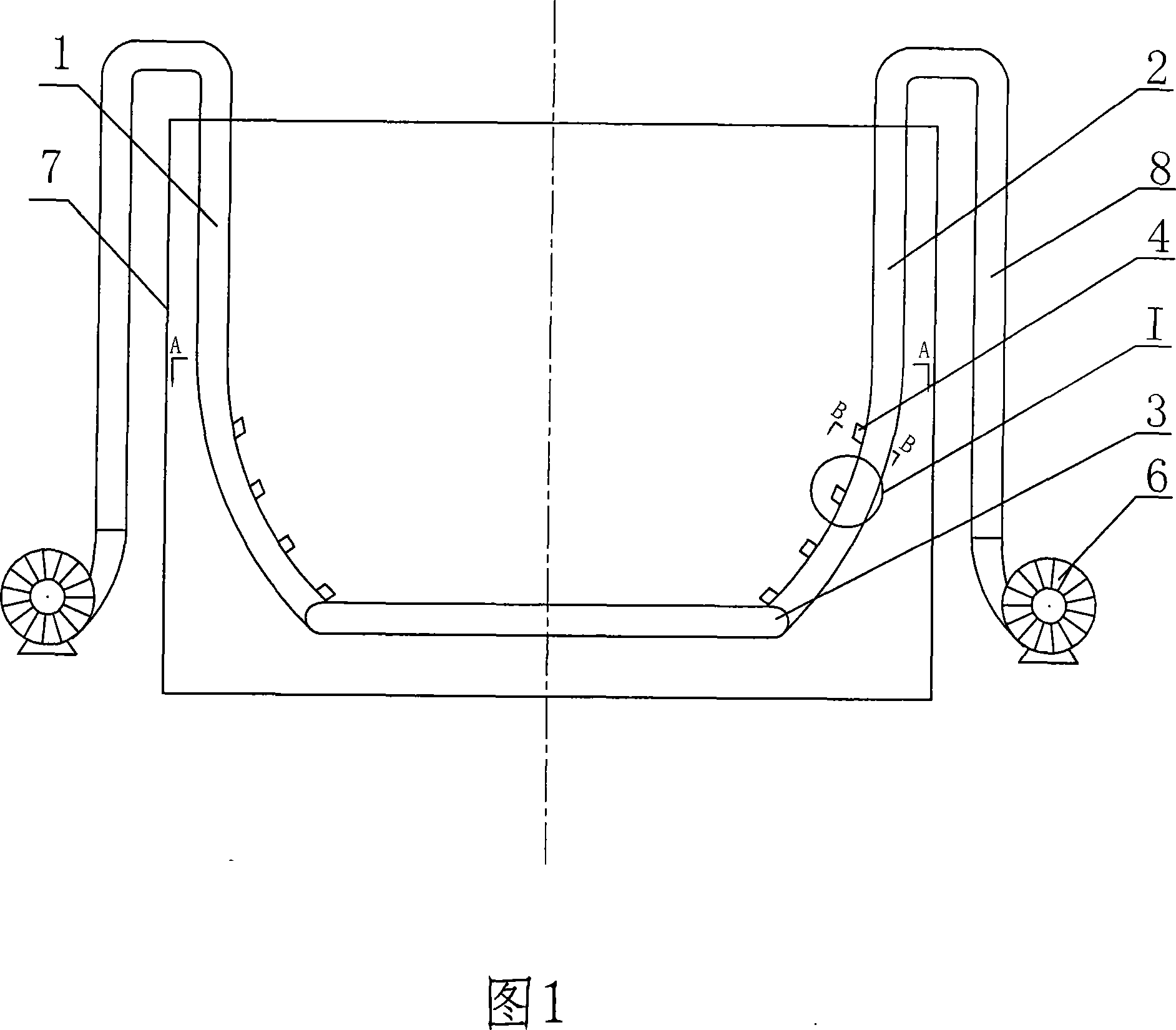

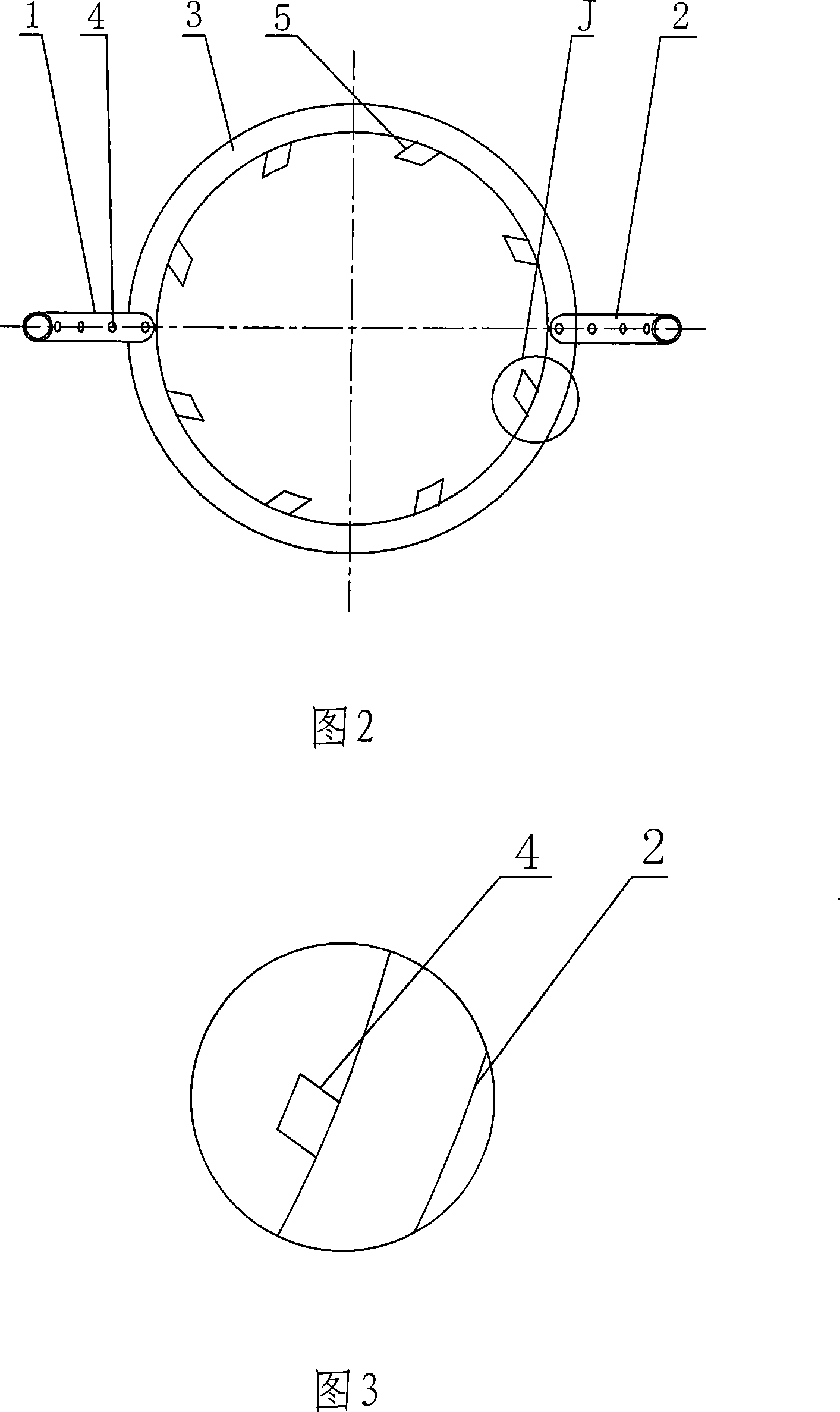

[0016] Embodiment 1, as shown in Figure 1 and Figure 2, the present invention is mainly made up of slurry pool 7, circular conduit 3, arc conduit 1,2 and air compressor 6, and circular conduit 3 is installed in the bottom of slurry pool 7 The two ends of a diameter of the circular conduit 3 are provided with a first arc conduit 1 and a second arc conduit 2, and the lower ends of the first arc conduit 1 and the second arc conduit 2 communicate with the circular conduit 3, The upper end protrudes from the slurry tank 7 and is connected with the output end of the air compressor 6 through an external connecting pipe 8 .

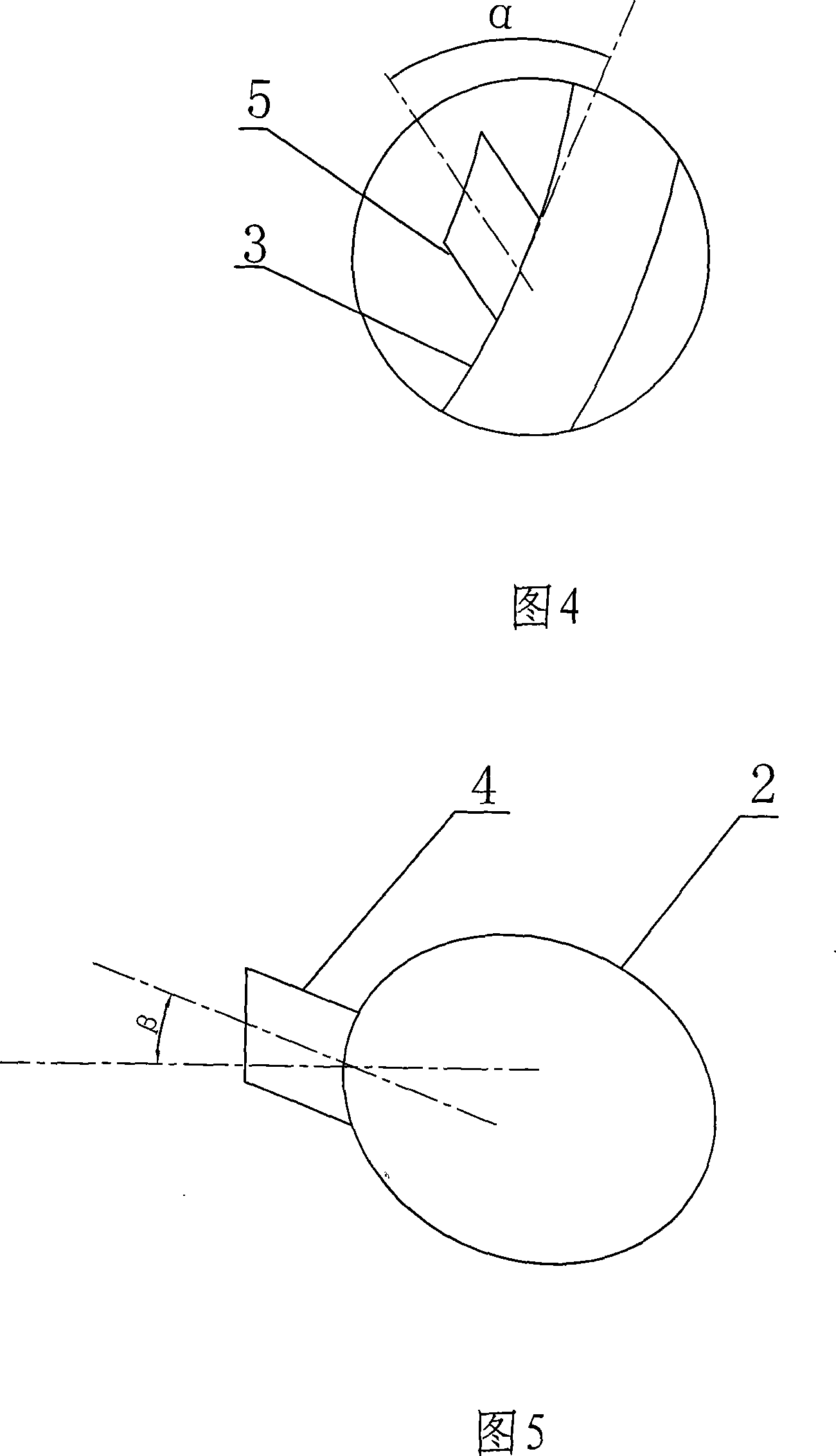

[0017] Further as shown in Fig. 3, Fig. 4 and Fig. 5, on the inner ring of described circular conduit 3, be welded with 8 lower jet tubes 5, the center line of this lower jet tube 5 and pass through this center line and circular duct 3 The tangent of the intersection point is an acute angle α. When α is 1 degree, the swirl velocity formed by the air ejected from ...

Embodiment 2

[0018] Embodiment 2, as shown in Figure 6, a first arc-shaped conduit 1, a second arc-shaped conduit 2, a third arc-shaped conduit 9 and a fourth The arc conduit 10, other structures are the same as that of embodiment 1, and four arc conduits blow compressed air into the slurry pool 7, so that the slurry is stirred more evenly, which is more conducive to the oxidation reaction. When the volume of the slurry pool is large, it needs For greater stirring kinetic energy, the number of curved conduits can continue to be increased.

[0019] At the same time, the present invention can also use the self-priming pump to introduce the mixture of air and slurry, thereby obtaining greater driving force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com