Apparatus for treating waste water for plating preprocessing process and processing method

A wastewater treatment and pretreatment technology, applied in metallurgical wastewater treatment, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of recovery and reuse or removal of peracid and metal salt or metal ion and other issues to achieve the effect of improving the quality of electroplating and reducing the cost of electroplating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

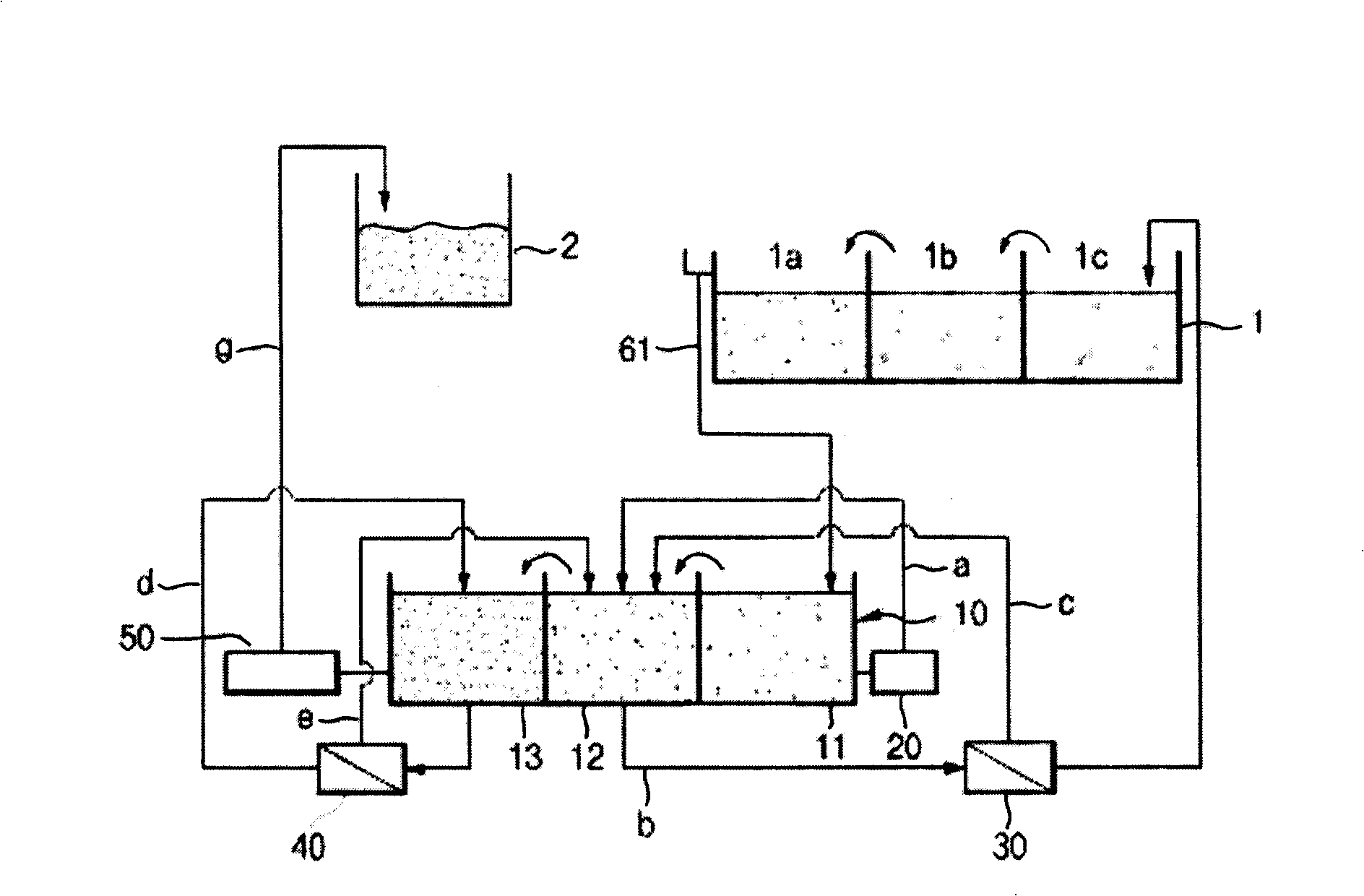

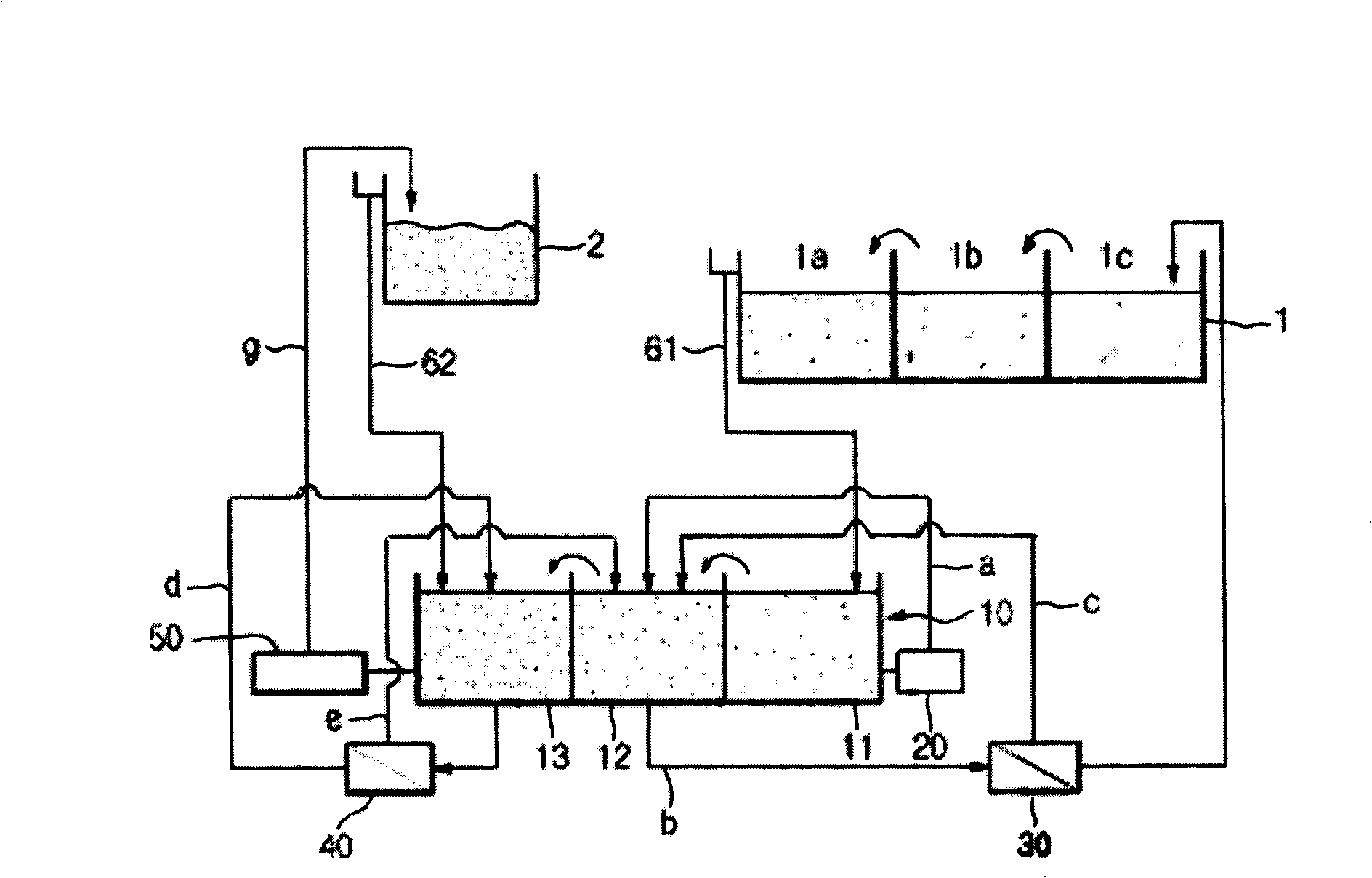

[0030] figure 1 Schematically, in order to remove foreign matter such as oil stains on the plated object to facilitate future electroplating, surface activation, waste water treatment for pickling process or activation process, and a waste water treatment device suitable for pretreatment process. This pretreatment wastewater treatment device is composed of a buffer tank 10 and a primary filter device 20 , a secondary filter device 30 , a 3rd filter device 40 , and a 4th filter device 50 .

[0031] According to the flow of the pickling process and the metal activation process of the object to be plated, the first washing tank 1a, the second washing tank 1b and the third washing tank 1c of the washing tank 1 are sequentially composed. The third washing tank 1c is located on the water supply side for supplying the replenishing liquid, and waste water moves sequentially to the first washing tank 1a through the third washing tank 1c and the second washing tank 1b. Therefore, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com