Diamond compound cutter bit head and its manufacturing method

A compound pick and manufacturing method technology, applied in the direction of cutting machinery, etc., can solve problems such as difficult temperature and pressure field, and achieve the effects of increased drilling speed, wide application range, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

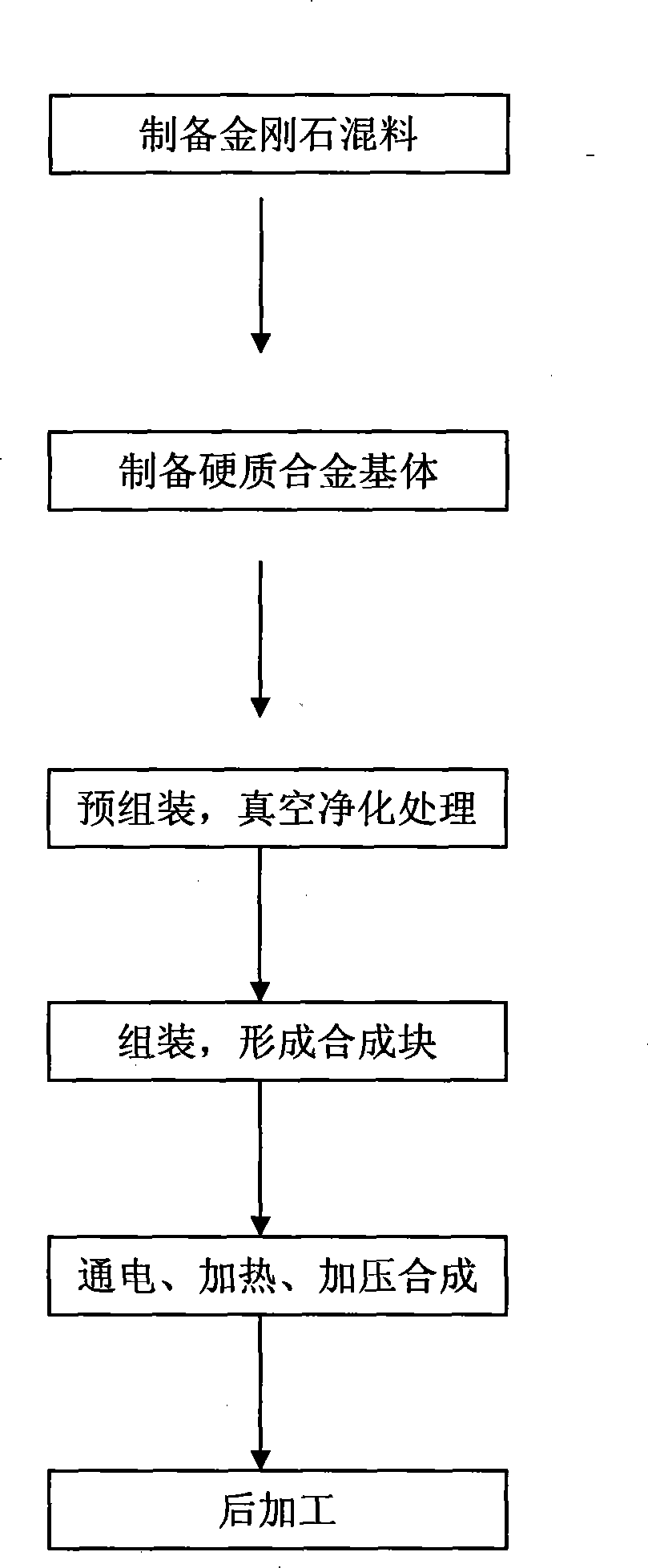

Method used

Image

Examples

Embodiment 1

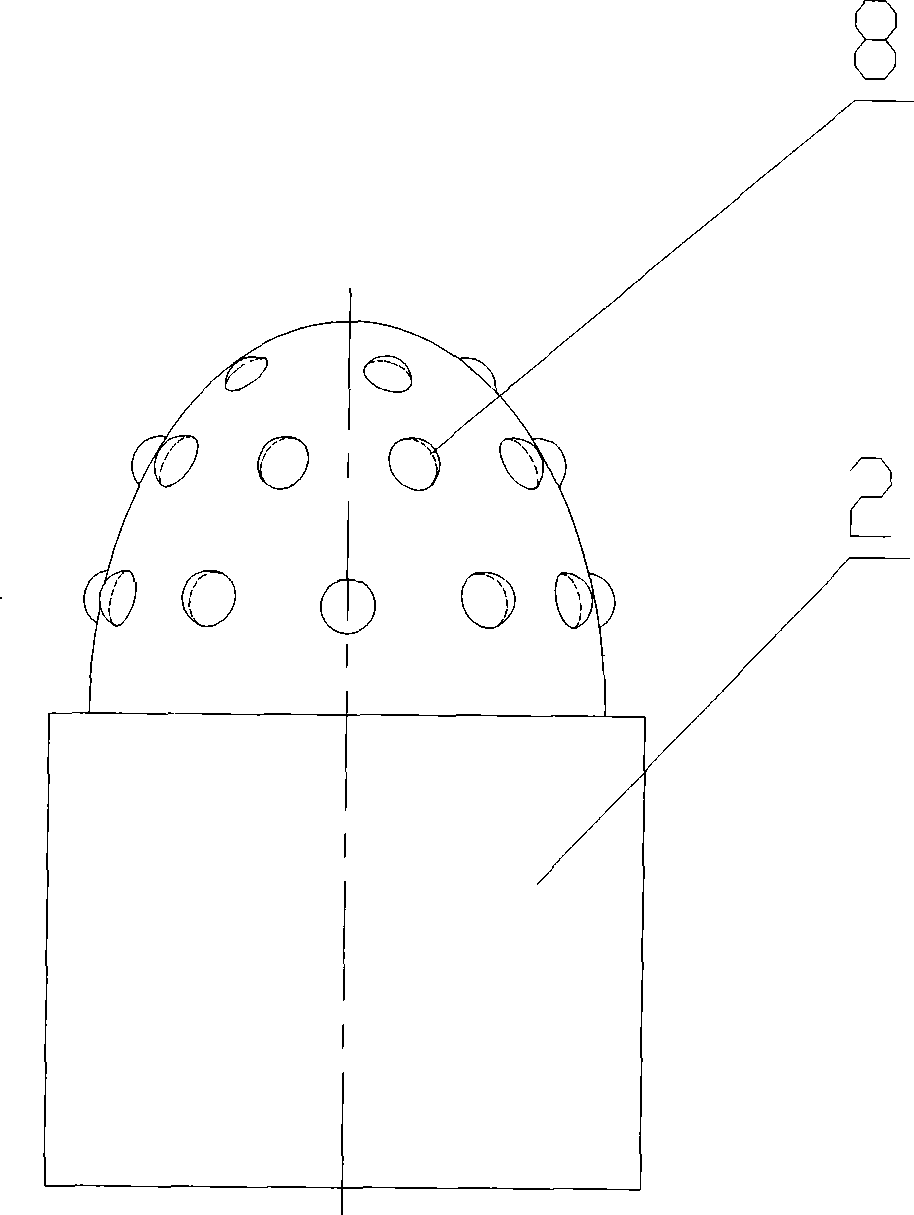

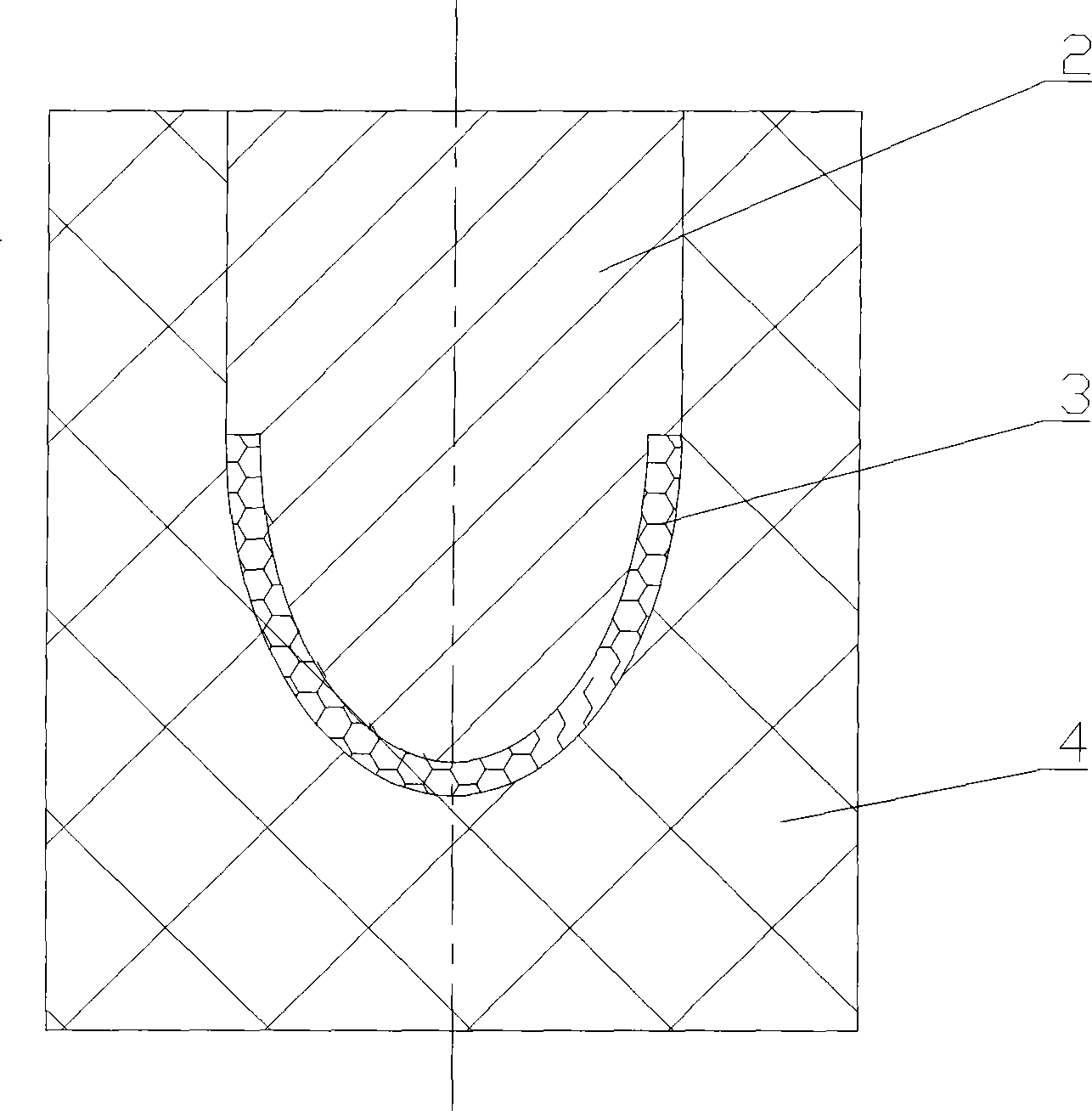

[0040] Embodiment 1: select the cemented carbide substrate 2 that the trade mark is YG16C, carry out the processing of degreasing, deoxidizing layer; The diamond mixture 3 that mixes is packed in the carbon tube 4, and the composition of diamond mixture 3 is: by weight Percentages: Diamond 80%, Silicon 8%, Cobalt 12%. Then put the cemented carbide matrix 2 into it again, prepress the diamond mixture 3, put the carbon tube 4 into the prepared pyrophyllite 1, and carry out the vacuum purification process. During the vacuum process, the temperature is 620 degrees, and the heating time is 2 Hour. Then, between the two ends of the carbon tube 4 and the pyrophyllite 1, a carbon sheet 7, a titanium circle 6 and a conductive steel ring 5 are sequentially loaded to form a composite block. Use the conductive steel ring 5 to energize and heat the synthesis block for 50 seconds, the synthesis pressure is 100Mpa, and the synthesis temperature is about 1580 degrees. The packed pyrophyllit...

Embodiment 2

[0041] Embodiment 2: select the cemented carbide substrate 2 that the trade mark is YG16C, carry out the processing of degreasing, deoxidizing layer; The diamond mixture 3 that mixes is packed in the carbon tube 4, and the composition of diamond mixture 3 is: by weight Percentages: Diamond 85%, Silicon 7%, Cobalt 8%. Then put the cemented carbide matrix 2 into it again, pre-press the diamond mixture 3, put the carbon tube 4 into the prepared pyrophyllite 1, and carry out vacuum purification treatment. The temperature during the vacuum treatment is 600 degrees, and the heating time is 2 Hour. Then, between the two ends of the carbon tube 4 and the pyrophyllite 1, a carbon sheet 7, a titanium circle 6 and a conductive steel ring 5 are sequentially loaded to form a composite block. Utilize the conductive steel ring 5 to energize and heat the synthesis block for 55 seconds, the synthesis pressure is 103Mpa, and the synthesis temperature is about 1520 degrees. The packed pyrophyl...

Embodiment 3

[0042]Embodiment 3: select the cemented carbide substrate 2 that the trade mark is YG16C, carry out the processing of degreasing, deoxidizing layer; The diamond mixture 3 that mixes is packed in the carbon tube 4, and the composition of diamond mixture 3 is: by weight Percentages: Diamond 86%, Silicon 7%, Cobalt 7%. Then put the cemented carbide substrate 2 into it again, prepress the diamond mixture 3, put the carbon tube 4 into the prepared pyrophyllite 1, and carry out the vacuum purification process. During the vacuum process, the temperature is 650 degrees, and the heating time is 2 Hour. Then, between the two ends of the carbon tube 4 and the pyrophyllite 1, a carbon sheet 7, a titanium circle 6 and a conductive steel ring 5 are sequentially loaded to form a composite block. Utilize the conductive steel ring 5 to energize and heat the synthesis block for 180 seconds, the synthesis pressure is 105Mpa, and the synthesis temperature is about 1560 degrees. The packed pyrop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com