Ejection air-supplying turbosupercharger

A turbocharger and ejector technology, which is applied in the direction of machines/engines, engine components, internal combustion piston engines, etc., can solve the problem of increasing capacity, volume, investment and energy consumption, and failing to play the role of jet ejection and air replenishment , high-pressure jet air inflow momentum and other problems, to achieve the effect of convenient regulation, simple structure and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the technical content of the present invention will be further described through the embodiments and in conjunction with the accompanying drawings.

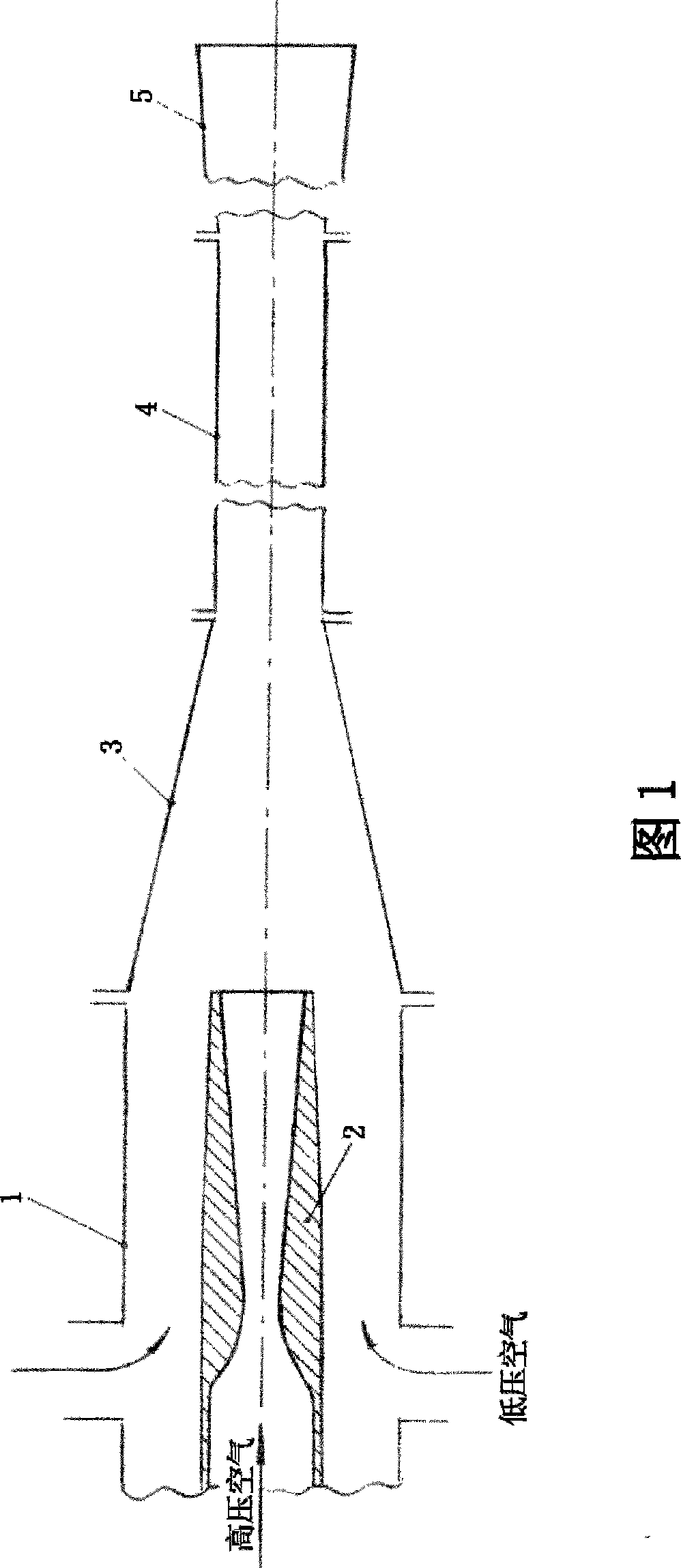

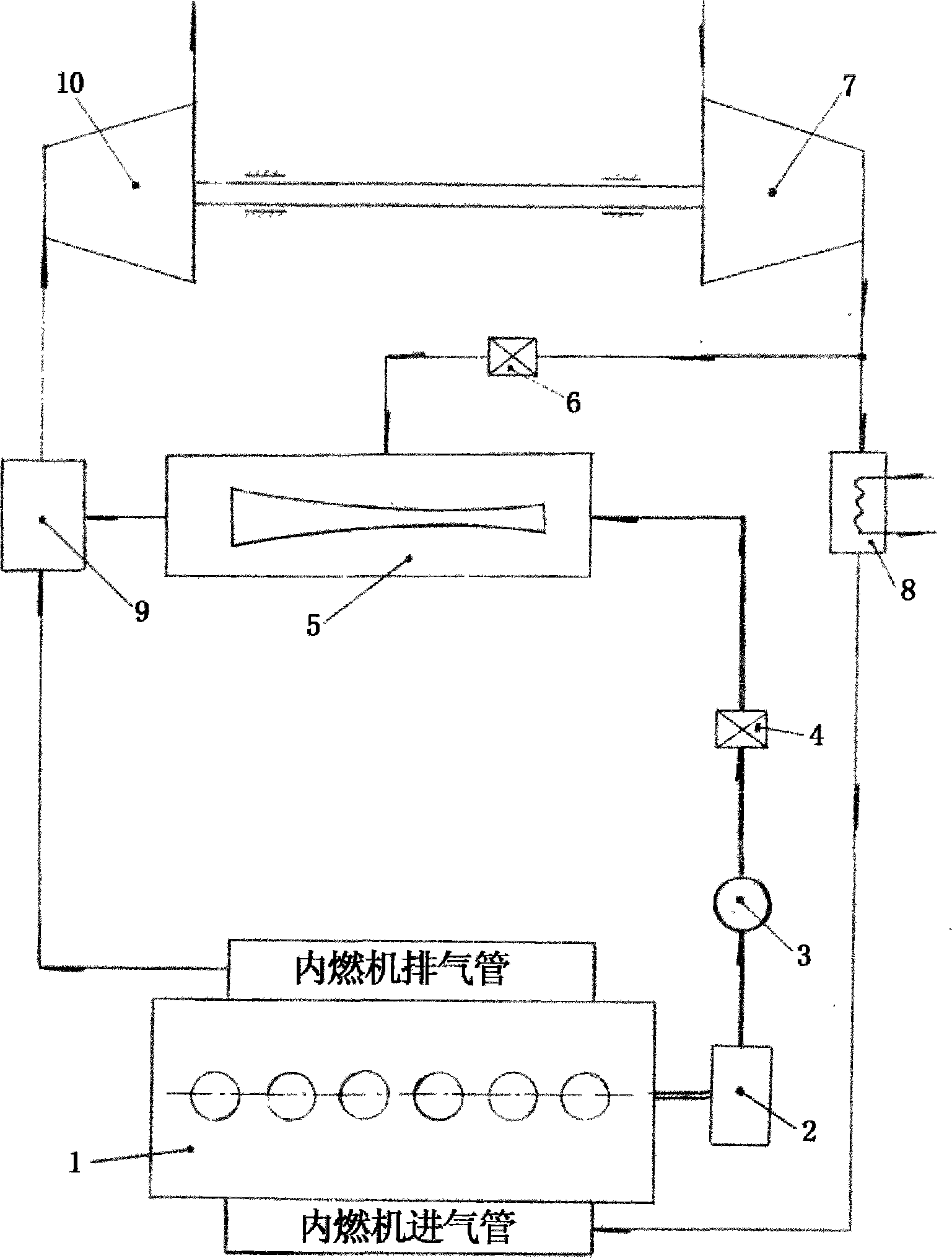

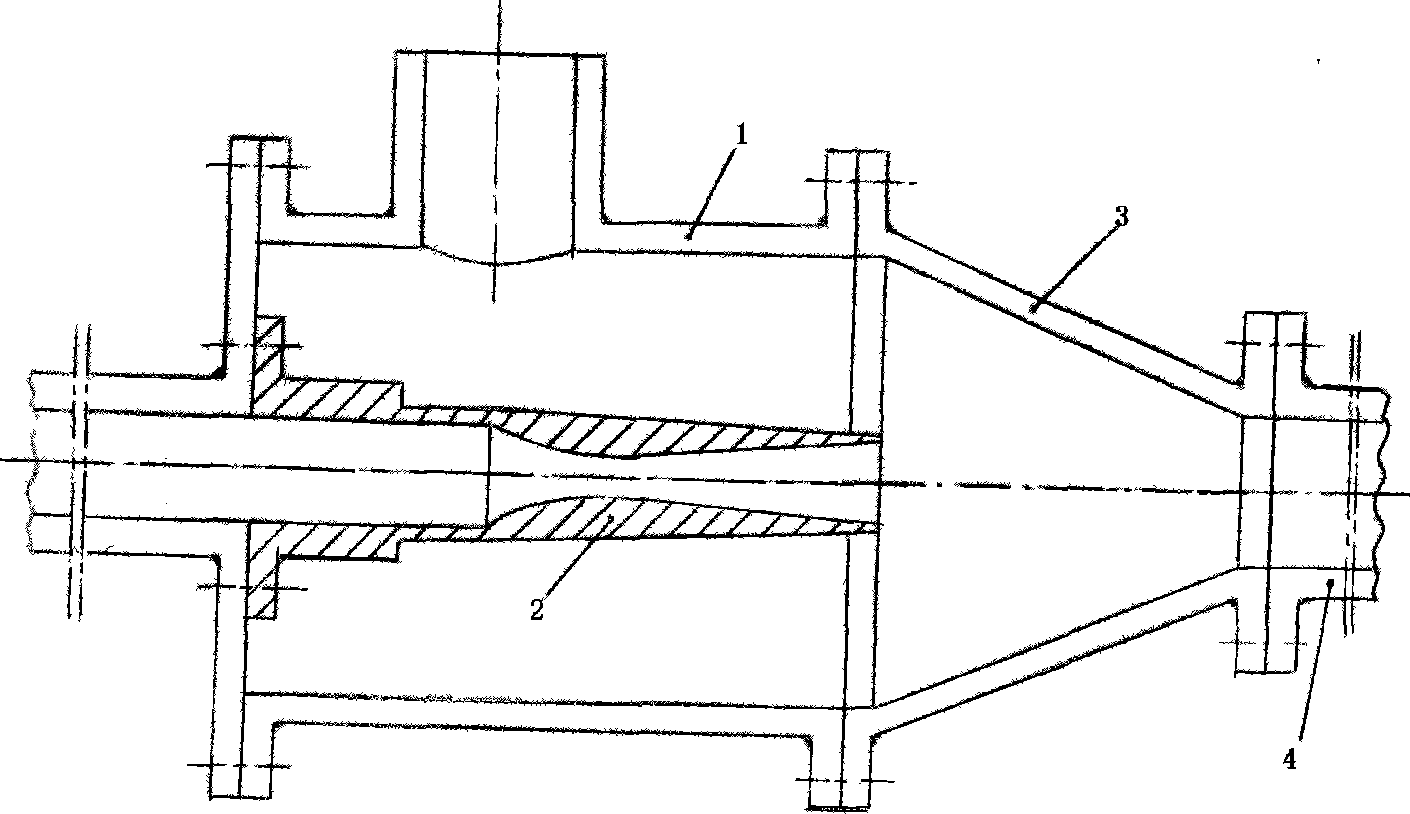

[0029] As mentioned above, the technical core of the present invention is to use the high-pressure compressed air flowing out from the air storage tank of the external source compressed air supply device, and the high-speed jet air formed by its expansion acceleration in the nozzle pipe of the gas ejector to induce The low-pressure pressurized air injected into the cylinder of the gas ejector by bypassing the compressor outlet of the turbocharger, the two are mixed in the mixing section of the ejector and boosted by the diffuser to form "supplementary air". Introduced into the guide pipe installed in the box-shaped air supply chamber between the outlet flange of the exhaust pipe of the internal combustion engine and the inlet flange of the turbine volute of the turbocharger, and finally near the outlet of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com