Induction heating power supply circuit

A technology of induction heating power supply and circuit, used in induction heating, induction current source, induction heating control and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

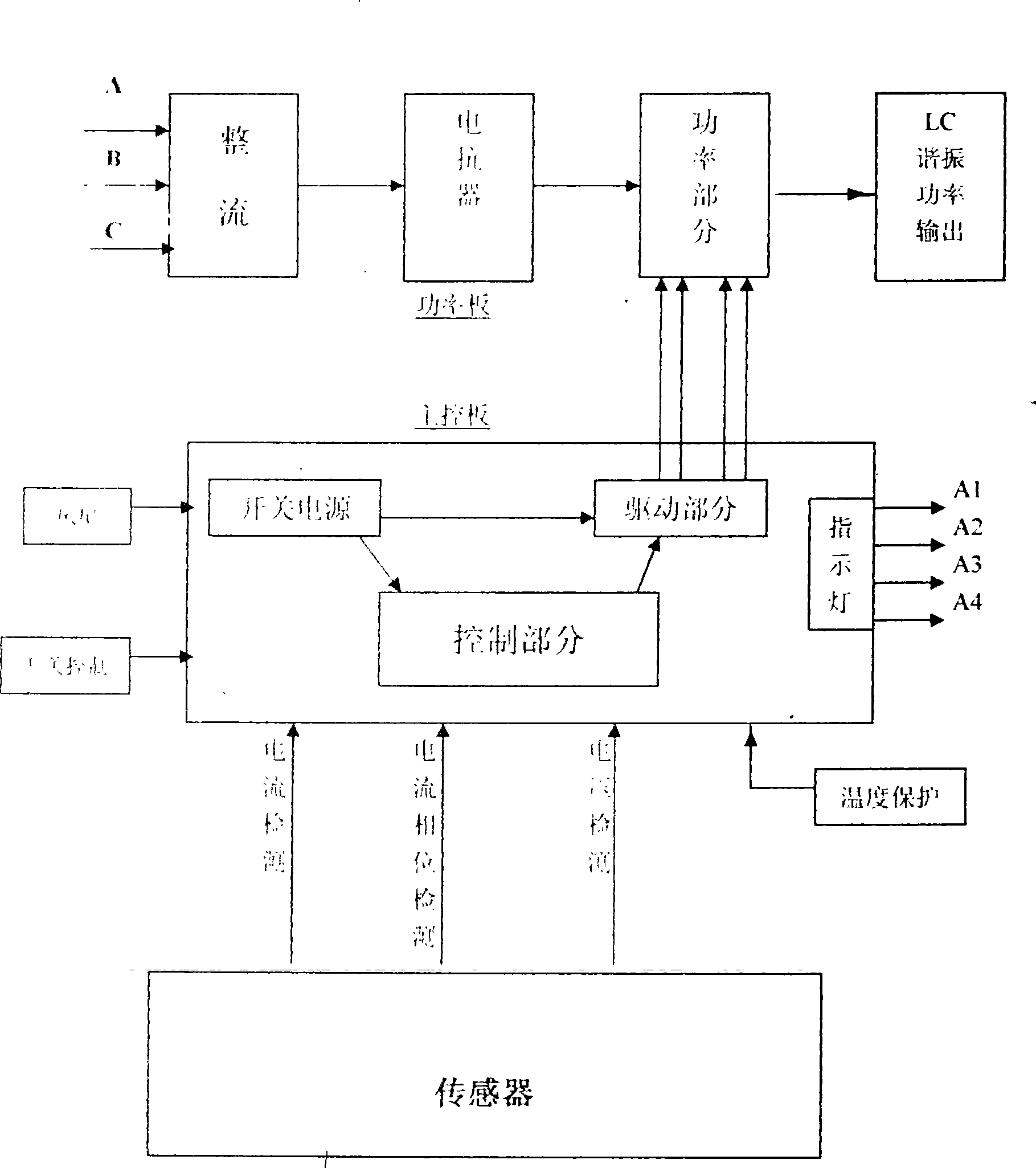

[0052] Please refer to the views, this embodiment is composed of a main control circuit part and a power circuit part.

[0053] 1. Main control part:

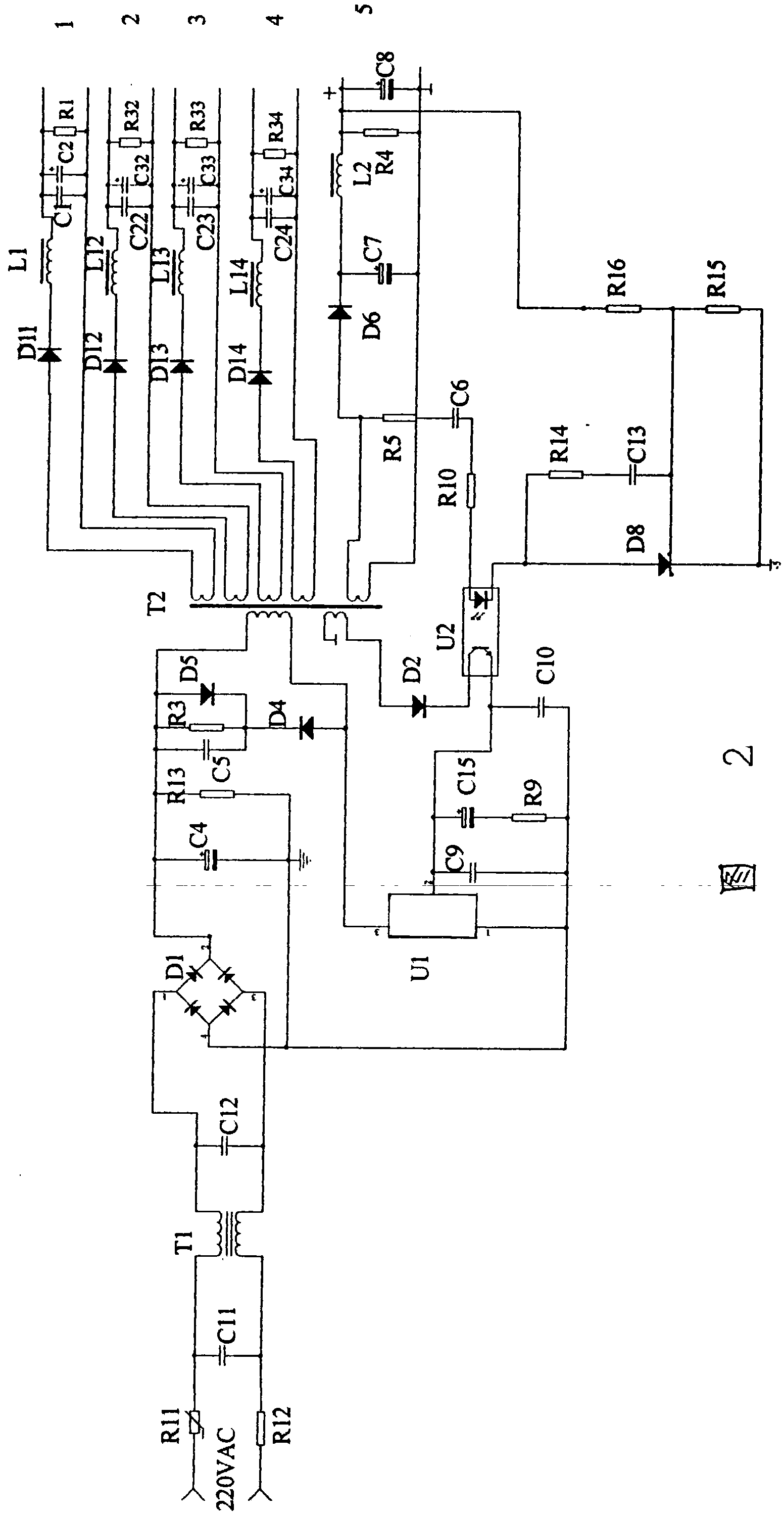

[0054] ①Switching power supply and drive part:

[0055]Mains AC 220V is connected to both ends of capacitor C11 and common mode inductor T1 through temperature insurance R12 and negative temperature coefficient thermistor R11, and the other two ends of common mode inductor are connected to both ends of capacitor C12 to filter out common After mode interference and differential mode interference, it is connected to the AC input terminal of rectifier bridge B for rectification. The output + of the rectifier bridge is connected to the '+' of the electrolytic capacitor C4, and the '-' of the rectifier bridge B is connected to the '-' of the electrolytic capacitor C4. The phase is connected to the hot ground for filtering, the resistor R3 is connected to the two ends of the electrolytic capacitor C4, the capacitor C5, the resistor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com