Fluid control apparatus

A fluid control device and fluid control valve technology, applied in fluid pressure control, valve device, flow control using electrical devices, etc., can solve problems such as uncomfortable flow control, complicated operation and time-consuming, and insufficient flow range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

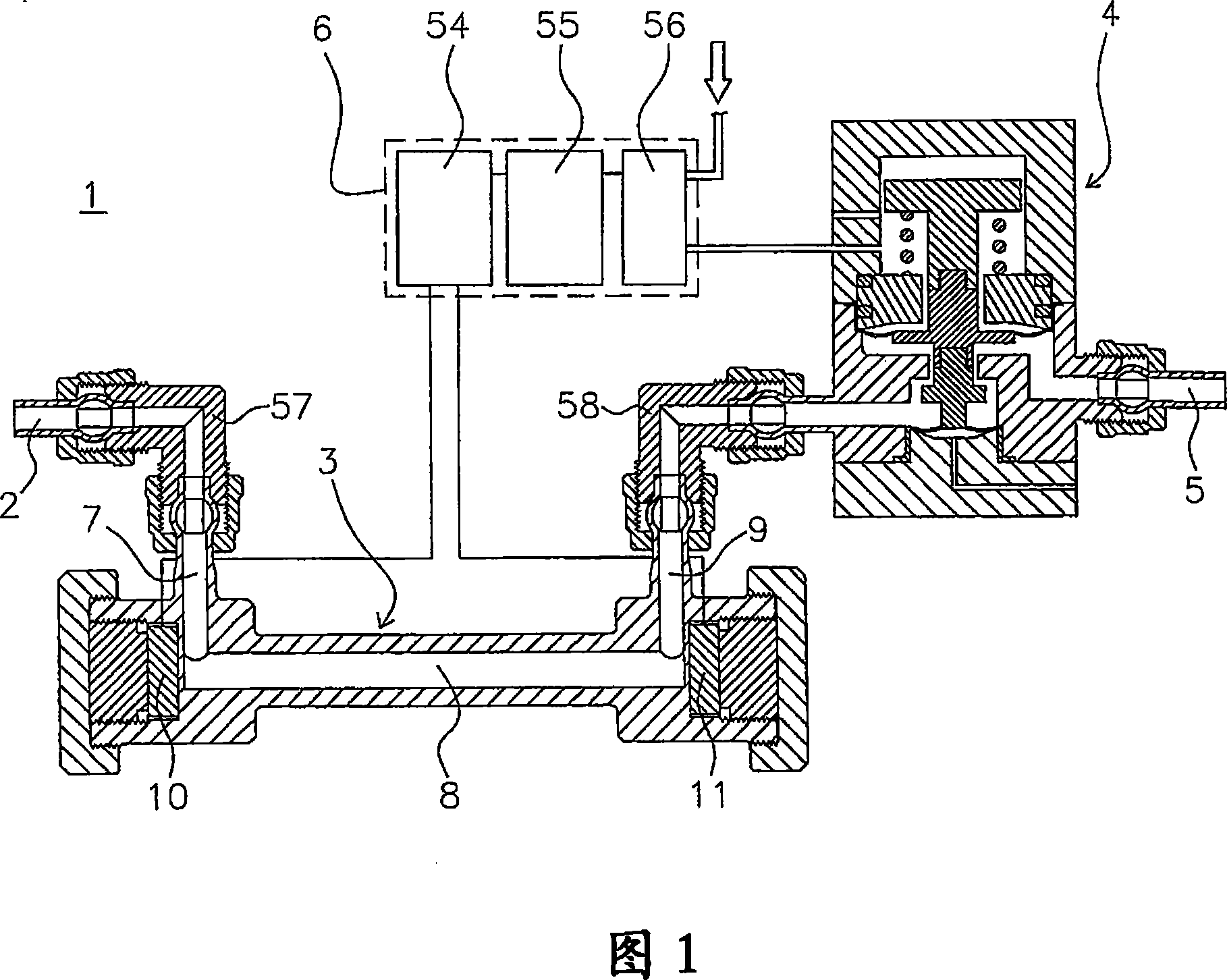

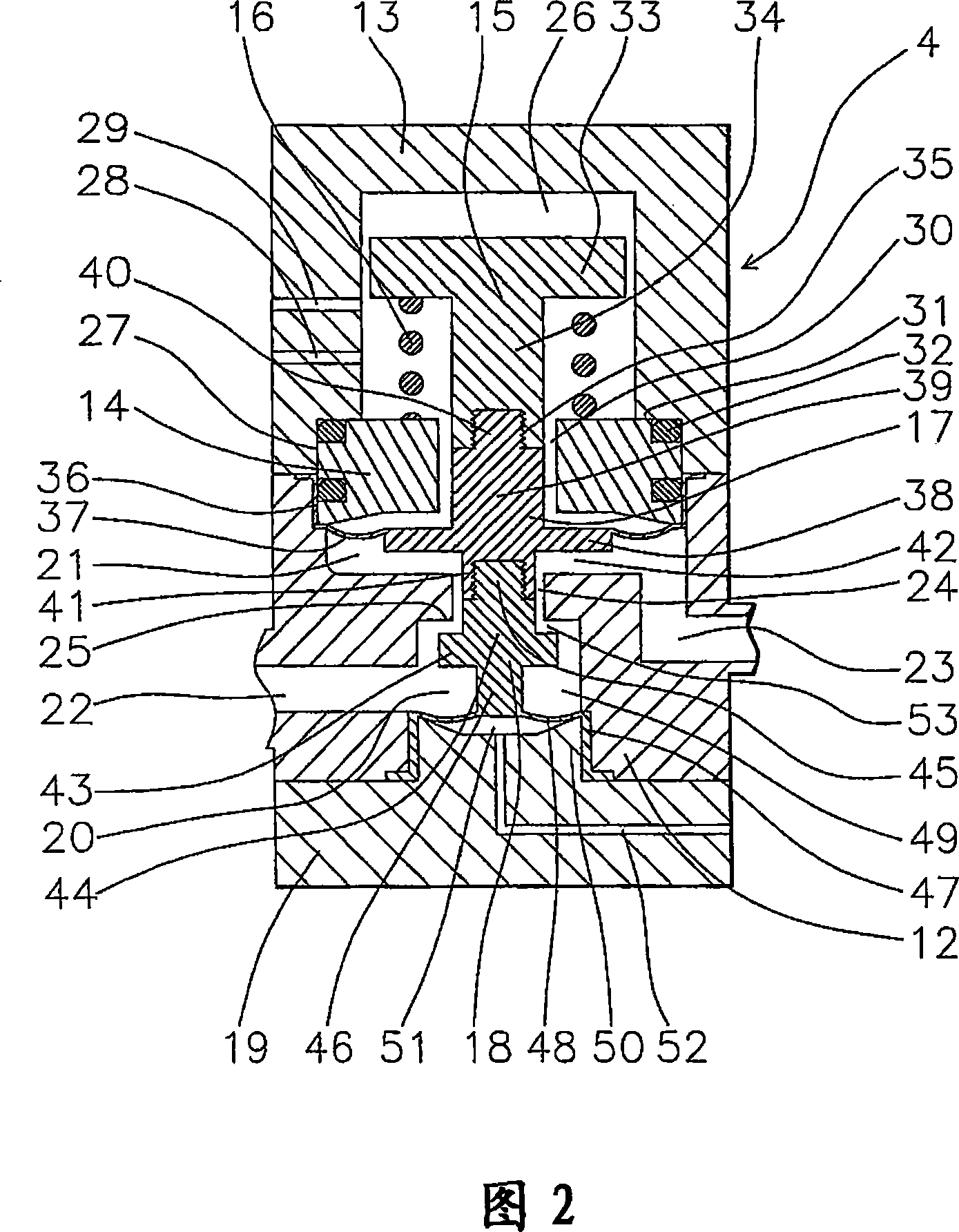

[0075] Hereinafter, a fluid control device as a first embodiment of the present invention will be described based on FIGS. 1 and 2.

[0076] 1 is a fluid control device installed in a semiconductor manufacturing device that performs an etching process of semiconductor manufacturing. The fluid control device 1 includes a fluid inflow port 2, a flow rate measuring device 3, a fluid control valve 4, a fluid outflow port 5, and a control unit 6, and their respective configurations are as follows.

[0077] 2 is a fluid inlet made of PFA. The fluid inflow port 2 is in communication with the inlet flow path 7 of the flow rate measuring device 3 described later.

[0078] 3 is a flow meter that measures the flow rate of the fluid. The flow meter 3 has: an inlet flow path 7, a straight flow path 8 arranged perpendicularly from the inlet flow path 7, and an outlet flow path 9 arranged perpendicularly from the straight flow path 8 and arranged in parallel with the inlet flow path 7 in the sam...

Embodiment 2

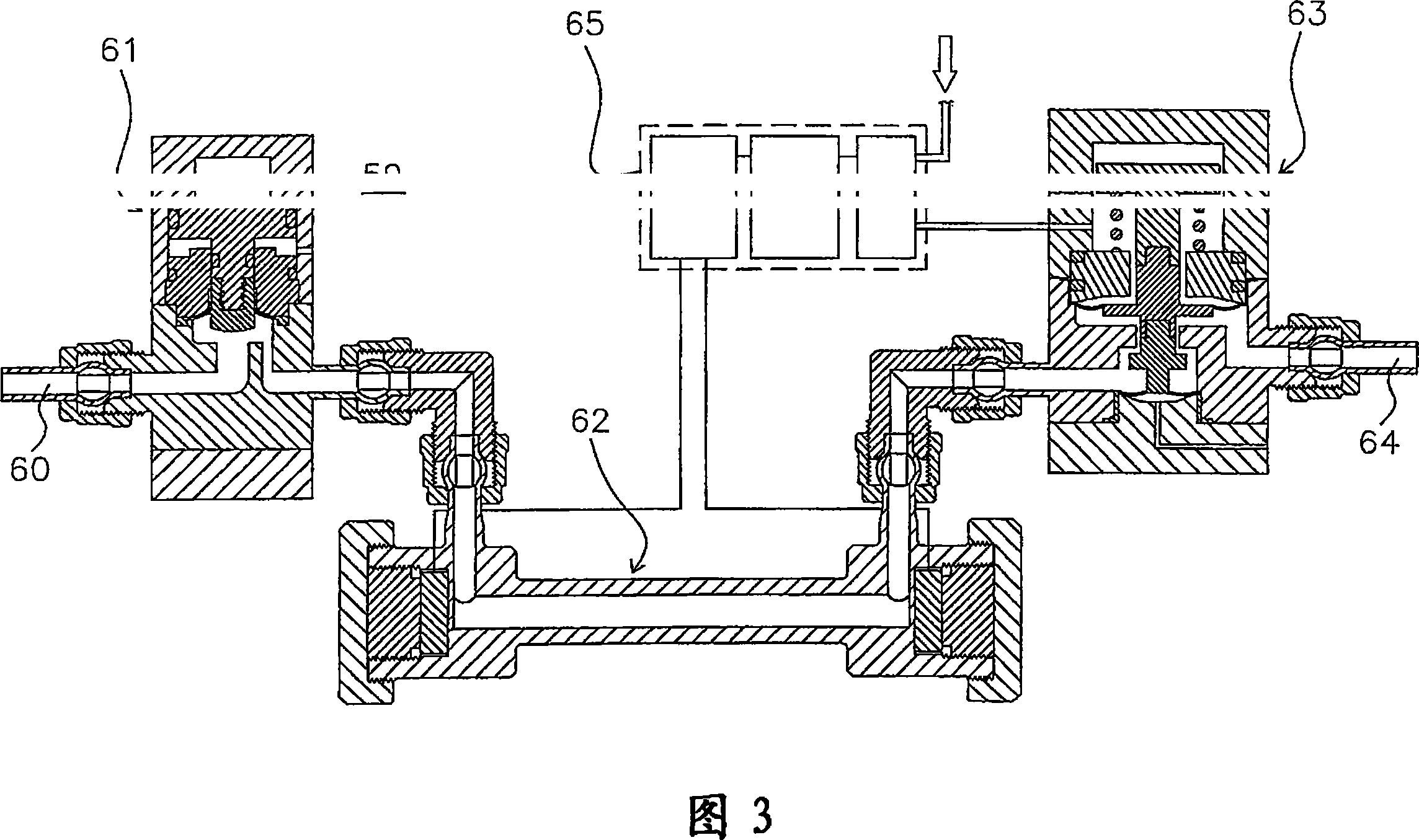

[0100] Next, a fluid control device as a second embodiment of the present invention will be described based on FIGS. 3 and 4.

[0101] 59 is a fluid control device. The fluid control device 59 includes a fluid inflow port 60, an on-off valve 61, a flow rate measuring device 62, a fluid control valve 63, a fluid outflow port 64, and a control unit 65, and their respective configurations are as follows.

[0102] 61 is an on-off valve. The on-off valve 61 includes a main body 66, a driving part 67, a piston 68, a diaphragm pressure member 69, and a valve core 70.

[0103] 66 is a body made of PTEF. It has a valve chamber 71 at the center of the upper end in the axial direction, and has an inlet flow path 72 and an outlet flow path 73 communicating with the valve chamber 71. The inlet flow path 72 communicates with the fluid inlet 60, and the outlet flow path 73 communicates with the flow meter 62. In addition, an annular groove 74 is provided outside the valve chamber 71 on the upper...

Embodiment 3

[0114] Next, a fluid control device as a third embodiment of the present invention will be described based on FIGS. 5 to 9.

[0115] 81 is a fluid control device. The fluid control device 81 includes a fluid inflow port 82, a flow rate measuring device 83, a fluid control valve 84, a throttle valve 85, a fluid outflow port 86, and a control unit 87, and their respective configurations are as follows.

[0116] 85 is a throttle valve with adjustable opening area. The throttle valve 85 includes a main body 88, a diaphragm 97, a second valve stem 106, a diaphragm pressing member 108, a first valve stem 114, a first valve stem support body 121, and a valve cover 125.

[0117] 88 is the main body made of PTFE. On the upper part of the main body 88 there is a valve chamber 90 having a substantially mortar shape formed with the following diaphragm 97, and on the bottom surface of the valve chamber 90 is formed a valve that performs a fully closed sealing of the flow path by pressing the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com