Piston molded line cam lift synthetic checking instrument

A cam lift, inspection instrument technology, applied in instruments, measuring devices, optical devices, etc., can solve the problems of large equipment investment, difficult maintenance, poor versatility, etc., to eliminate coaxiality errors, improve detection efficiency, and manufacture. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

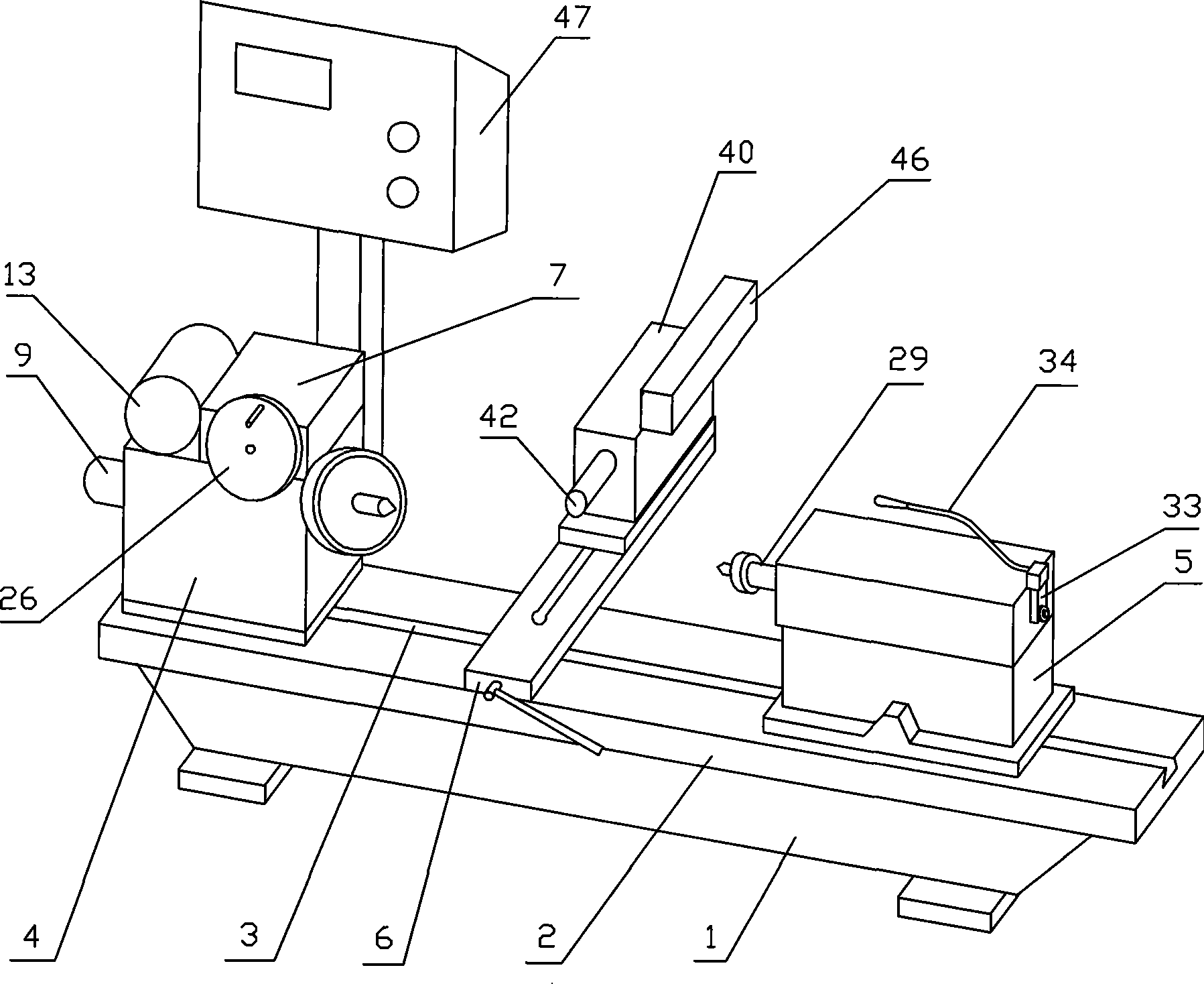

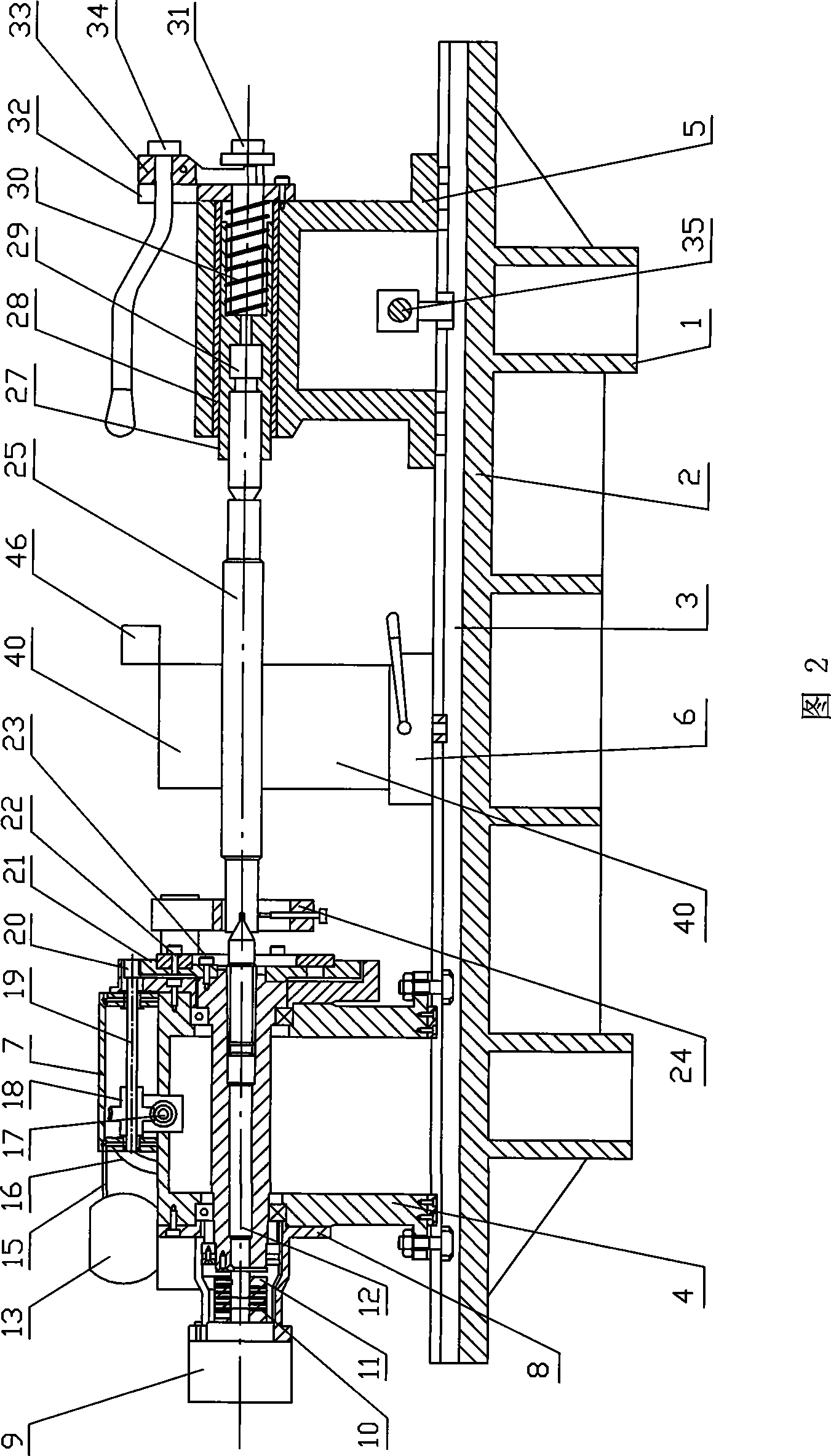

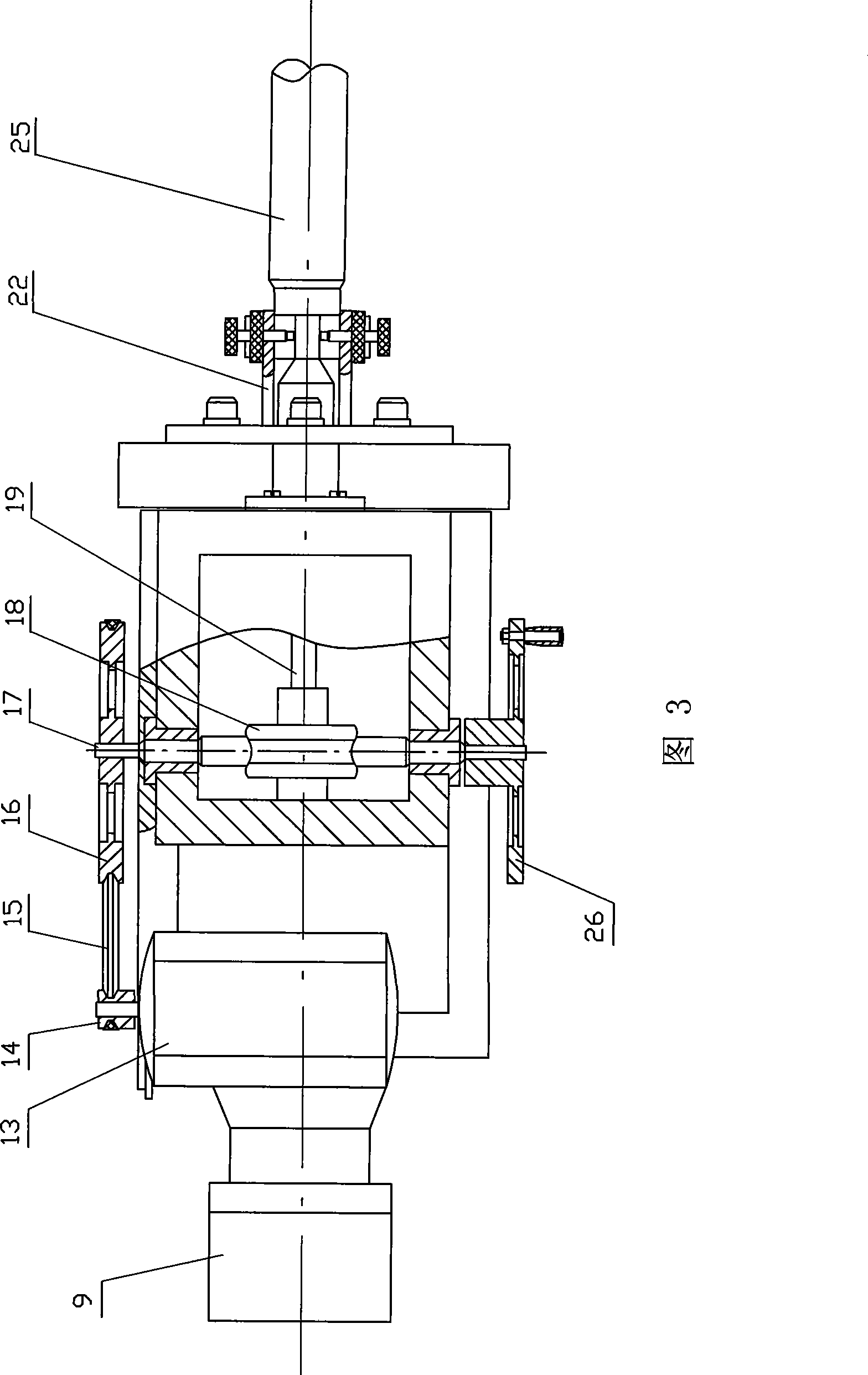

[0011] Depend on figure 1 , Fig. 2, Fig. 3 can be seen, the piston profile cam lift comprehensive inspection instrument of the present invention comprises the bed 1 and the guide rail platform 2 on the bed, the guide rail platform 2 is provided with T-shaped groove 3, is connected laterally on the T-shaped groove 3 Main shaft seat 4 and tail stock 5 are arranged, length measuring instrument base plate 6 is arranged longitudinally, and main shaft seat 4 is fixedly connected with T-shaped slot 3 with bolts and nuts. The main shaft seat 4 is equipped with a transmission seat 7, and the left end is connected to the encoder interface seat 8. The circular grating rotary encoder 9 is mounted on the encoder interface seat 8 and connected with bolts. There is an elastic sheet 10 in the middle of the circular grating rotary encoder 9. The shaft device 11 bears torque, and the shaft coupling 11 is connected with the main shaft 12 , and the main shaft 12 passes through the bearings at bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com