Complete optical fiber polarization type pressure measurement method and sensing device

An all-fiber, pressure technology, which is applied in the transmission of sensing components by optical devices, the measurement of force by measuring the change of optical properties of materials when they are stressed, and the coupling of optical waveguides. It can solve the problems of large insertion loss and system space optics. There are many problems such as many devices and complicated assembly, so as to reduce the cost of materials, simplify the measurement device, and reduce the insertion loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The all-optical fiber polarization pressure measurement method and sensing device proposed in the present invention are described in detail as follows in conjunction with the accompanying drawings and embodiments:

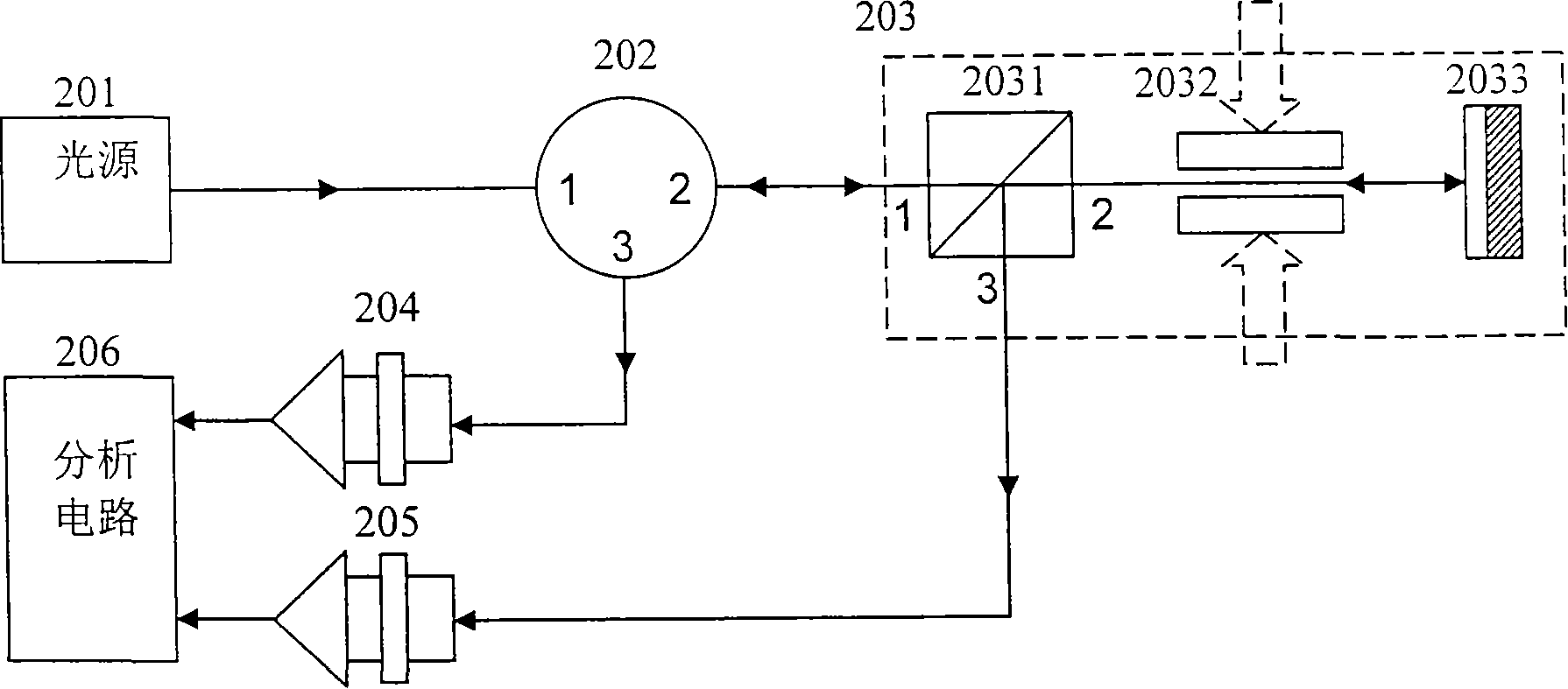

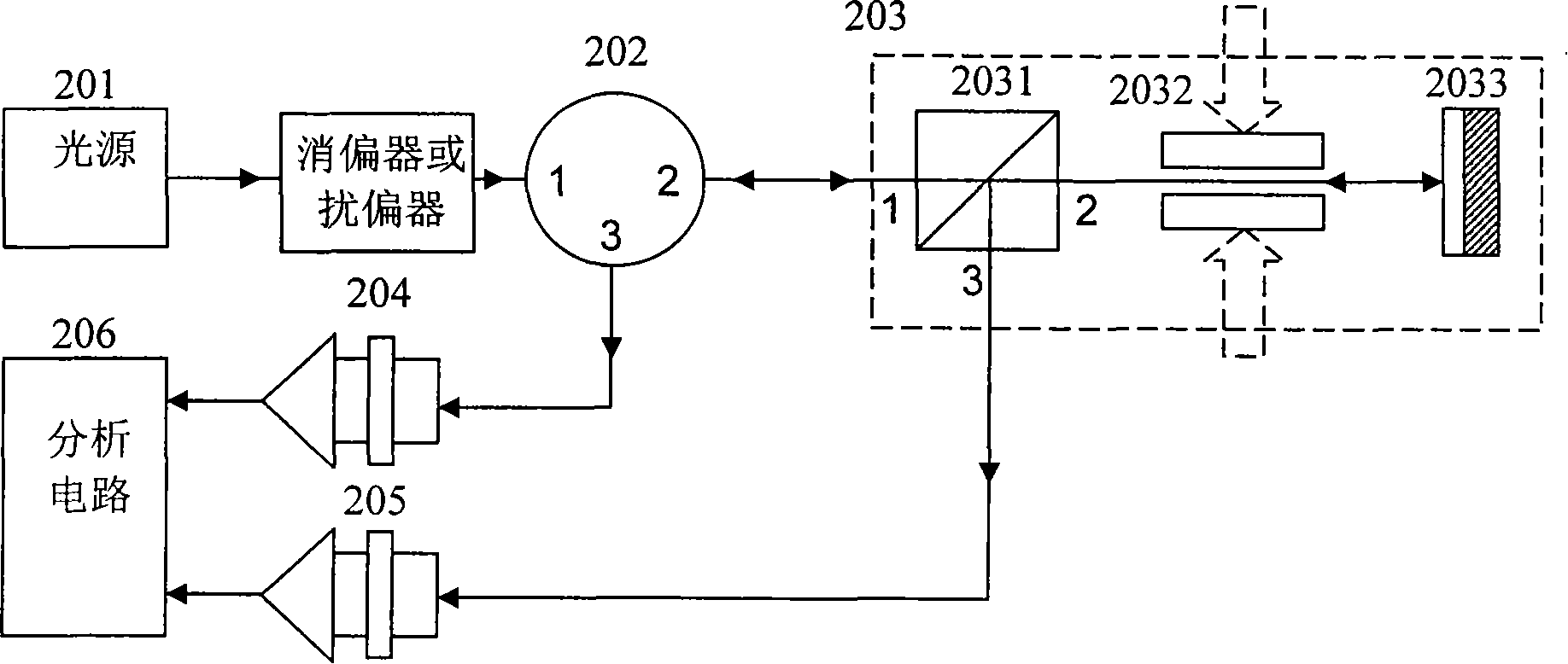

[0054] Embodiment 1 of the all-fiber polarization optical pressure measurement sensor device designed by the present invention, its composition structure is as follows figure 2 As shown, the device includes: a light source 201, an optical circulator 202, a sensing mechanism 203 composed of a polarization beam splitter 2031, a sensing fiber 2032 and a reflector 2033, two optical detectors 204, 205, a Analysis circuit 206; the connection relationship of each component is:

[0055] The optical output end of the light source 201 is connected to the port 1 of the optical circulator;

[0056] Port 2 of the optical circulator is connected to port 1 of the polarization beam splitter 2031 in the sensing mechanism 203, and port 3 of the optical circulator is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com