High speed servo controller with parallel processing structure based on FPGA

A servo controller and parallel processing technology, applied in the field of servo controller and high-speed servo controller, can solve the problem that the servo controller can not meet the requirements of control speed and the cost is high, and achieve shortened control cycle, fast calculation speed, suitable for wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be further described.

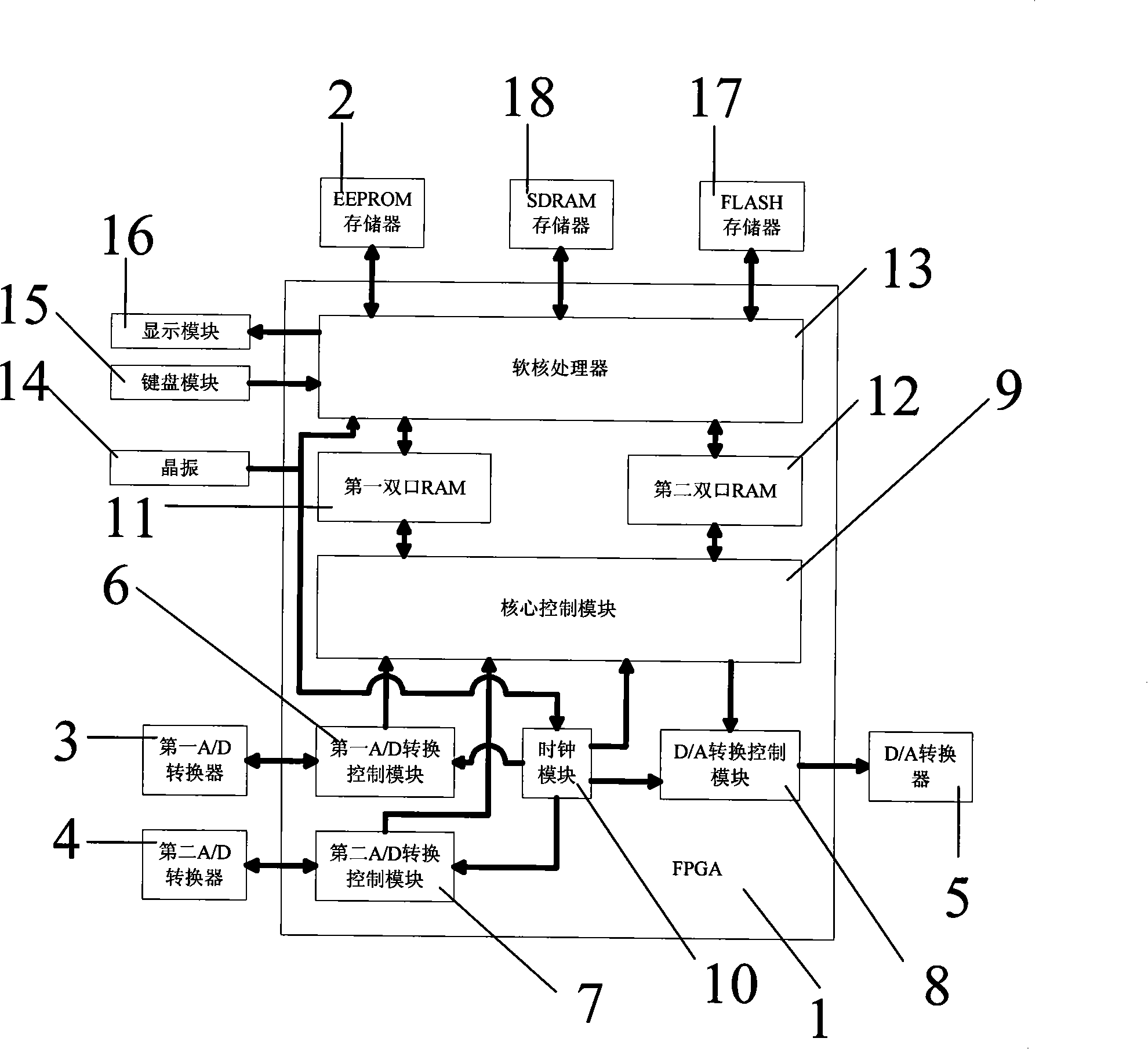

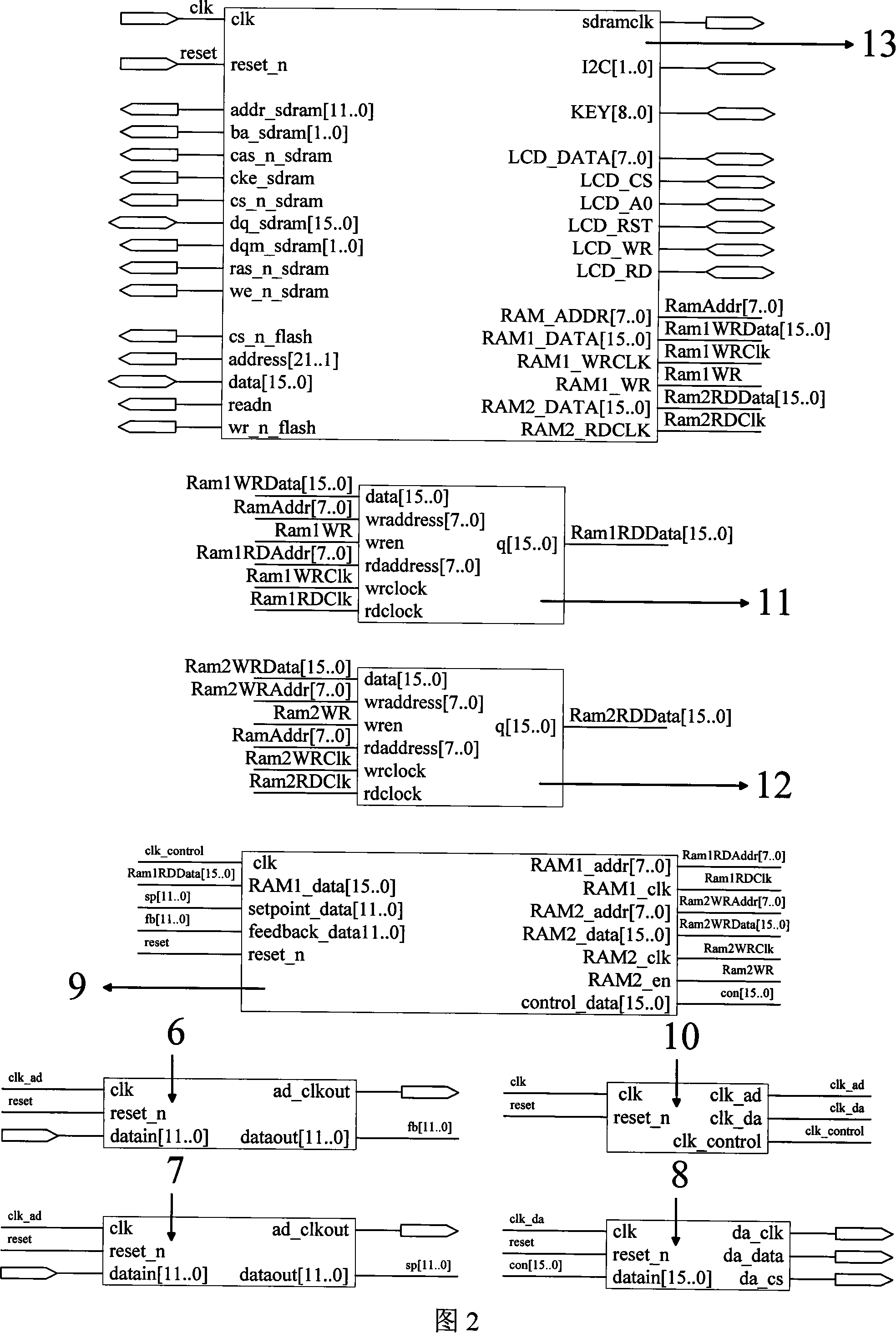

[0012] see figure 1 , FPGA-based high-speed servo controller with parallel processing structure includes FPGA 1, two A / D converters 3, 4, D / A converter 5, crystal oscillator 14, keyboard module 15, display module 16, FLASH memory 17, SDRAM memory 18 and EEPROM memory 2, wherein Field Programmable Logic Gate Array 1 includes two A / D conversion control modules 6,7, D / A conversion control module 8, core control module 9, clock module 10 for controlling calculation , two dual-port RAM11,12 and soft core processor 13, two A / D conversion control modules 6,7 are connected with two A / D converters 3,4 respectively, two A / D conversion control modules 6, The data output end of 7 is connected with the data input end of core control module 9 respectively, and the data output end of core control module 9 is connected with the data input end of D / A conversion control module 8, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com