Method for the production of a semiconductor component comprising a planar contact, and semiconductor component

A semiconductor and device technology, applied in the field of semiconductor devices, can solve problems such as thermal resistance limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

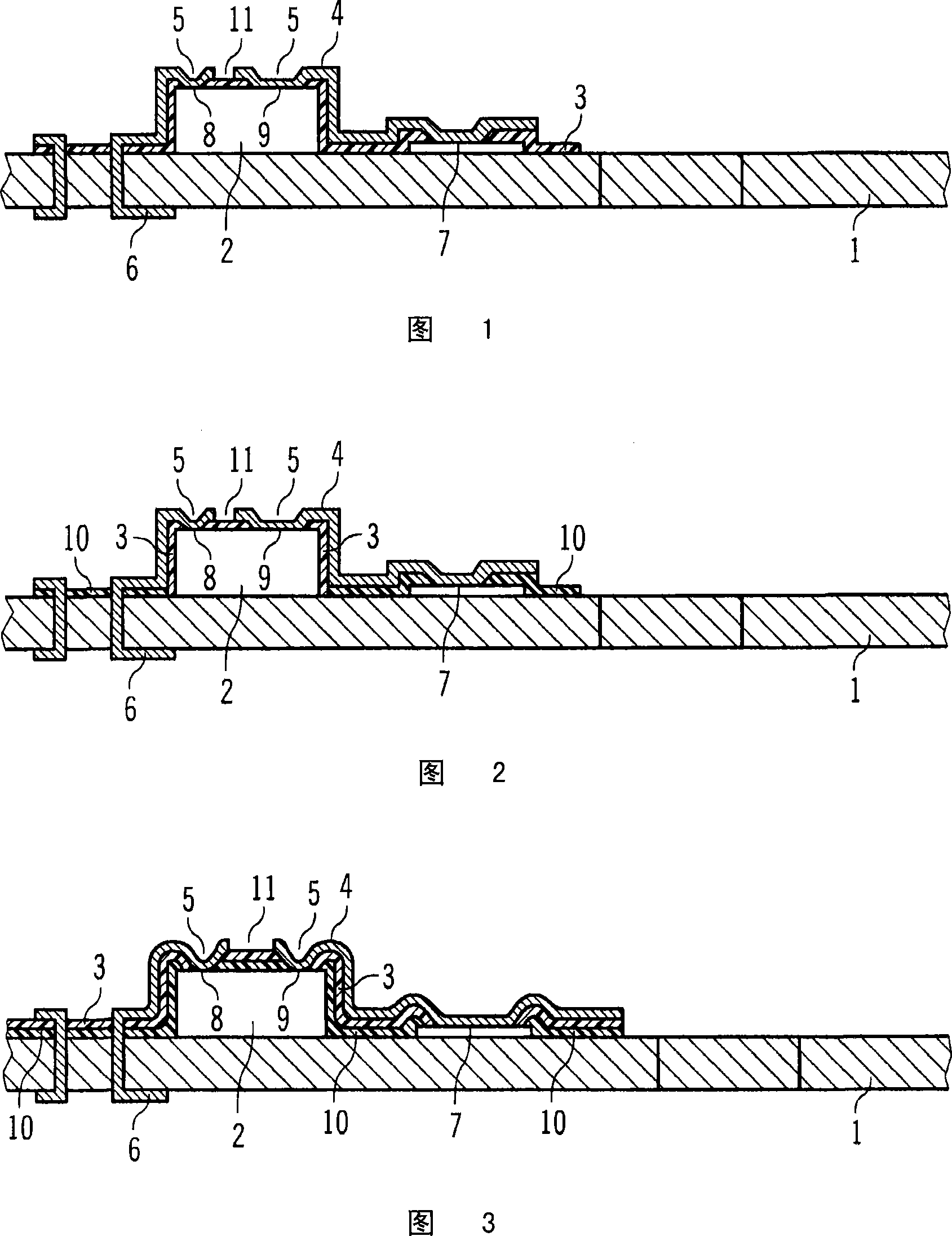

[0028] FIG. 1 shows a semiconductor device in which an LED chip 2 is arranged on a substrate 1 . The substrate 1 can be, for example, a wafer, a printed circuit board (PCB) and / or a flexible material (flex material).

[0029] An insulating layer 3 of glass, for example a thin layer of borosilicate glass, is applied on the substrate 1 and on the LED chip 2 . This borosilicate glass layer serves both as a thermal protection layer for the LED chip 2 and as a thermal protection layer for the substrate 1 . The glass coating 3 thus protects the LED chip 2 and the substrate 1 from environmental influences such as moisture, dust or radiation.

[0030] The insulating layer 3 also serves for the electrical insulation between subregions of the LED 2 , in particular the sides of the LED chip 2 , and the electrical connection 4 for the areal electrical contacting of the LED chip. A planar contact is to be understood here as a wireless contact formed by means of a structured metal layer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com