Inductive element and manufacturing method thereof

A technology of inductance components and manufacturing methods, which is applied in the fields of electrical components, inductance/transformer/magnet manufacturing, transformer/inductor components, etc., and can solve problems such as inability to implement concretely, ambiguity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

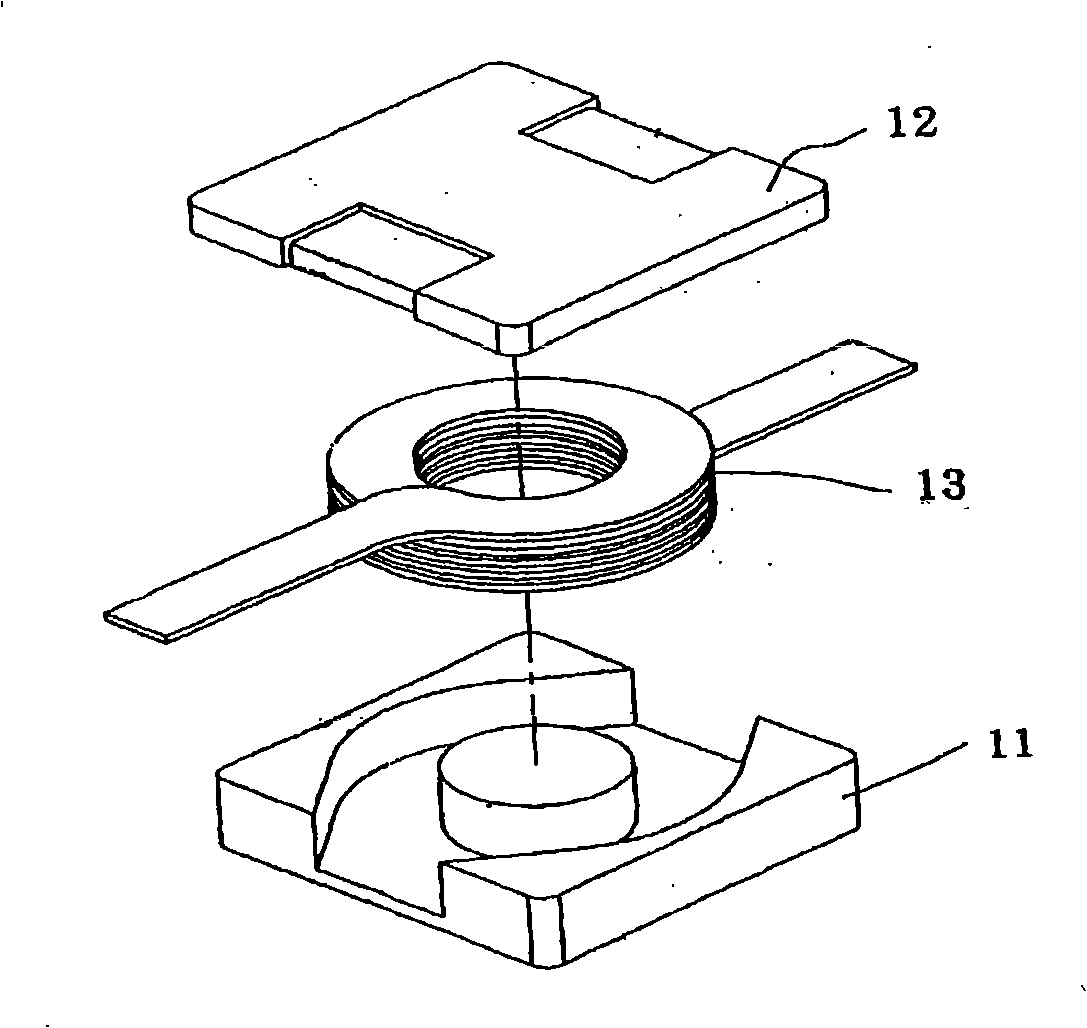

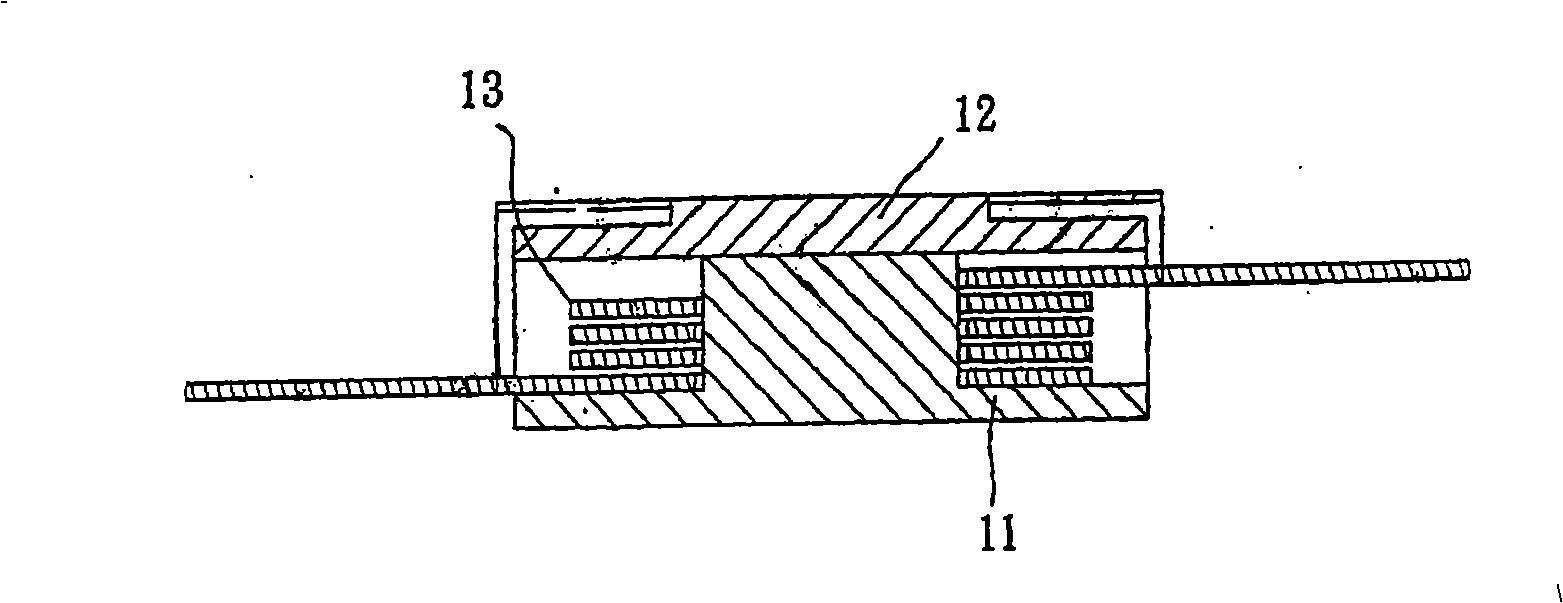

[0024] see figure 1 , figure 2 . In the prior art, the inductance element is composed of upper and lower magnetic cores 11, 12 and a coil 13. The lower magnetic core has a groove to accommodate the coil. After the coil 13 is placed in the lower magnetic core 11, the upper magnetic core 12 and its corresponding cover combined, and then glued and baked to make the two magnetic cores a clad body.

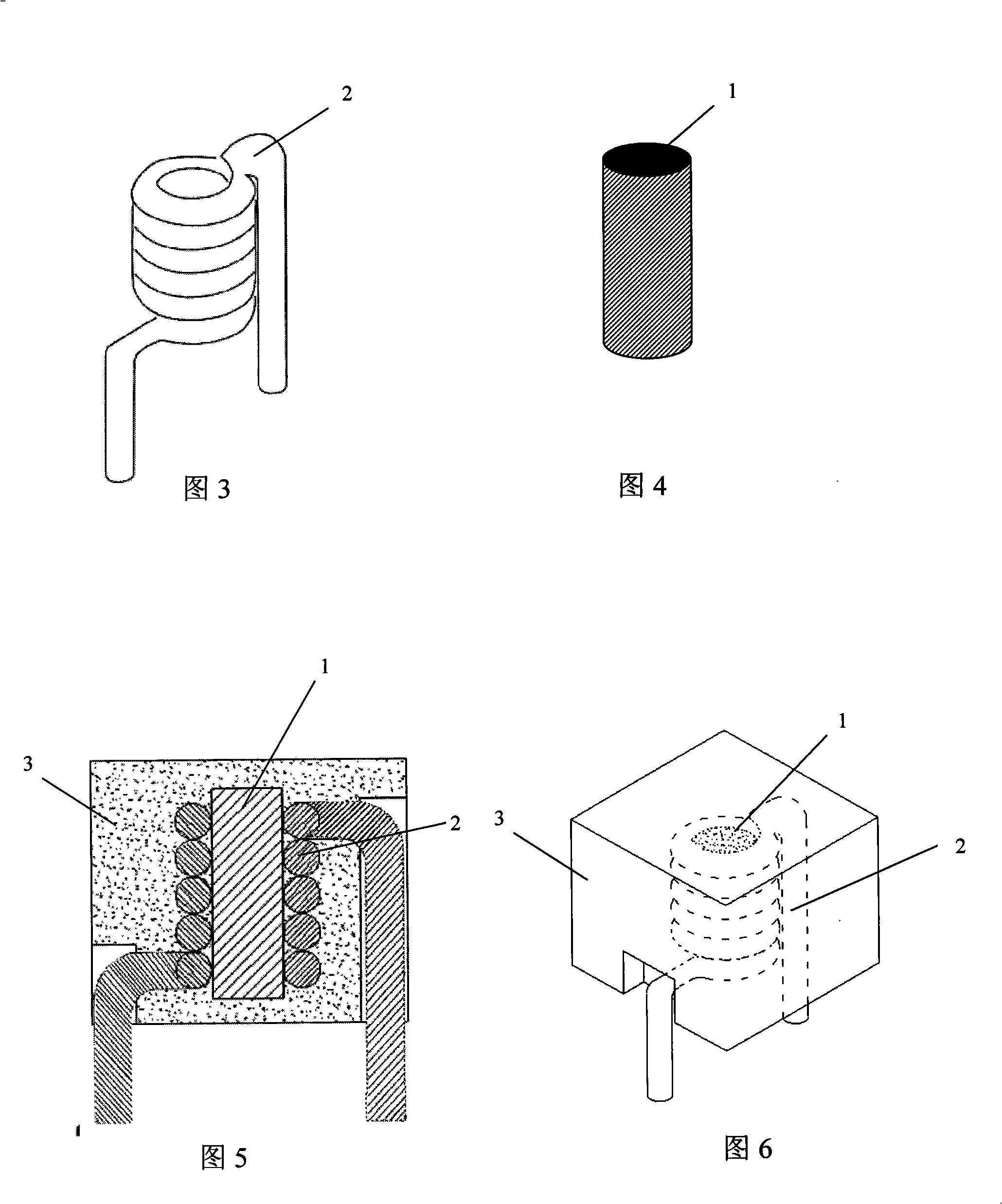

[0025] See Figure 3, Figure 4, Figure 5, Figure 6. The present invention includes a magnetic rod 1 and a coil 2. The coil is wound outside the magnetic rod. After the two are combined, they are put into a preset mold; the covering body 3 is a mixture of magnetic conductive powder and polymer insulating resin and other additives. , are powders with a particle size of less than 50 μm, mixed uniformly in a certain proportion, heated to 80-350°C to make it a fluid, injected into the mold from the injection molding machine, and condensed to form the coating body 3 .

[0026] The follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com