Dual wavelength synthetic pumping compact type laser system

A dual-wavelength laser, laser system technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problem of increasing the difficulty of output laser identification and extraction, reducing laser light-to-optical conversion efficiency, and the inability of lasers to use pump light, etc. problem, to achieve the effect of improving beam quality, improving beam quality, reducing volume and working power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

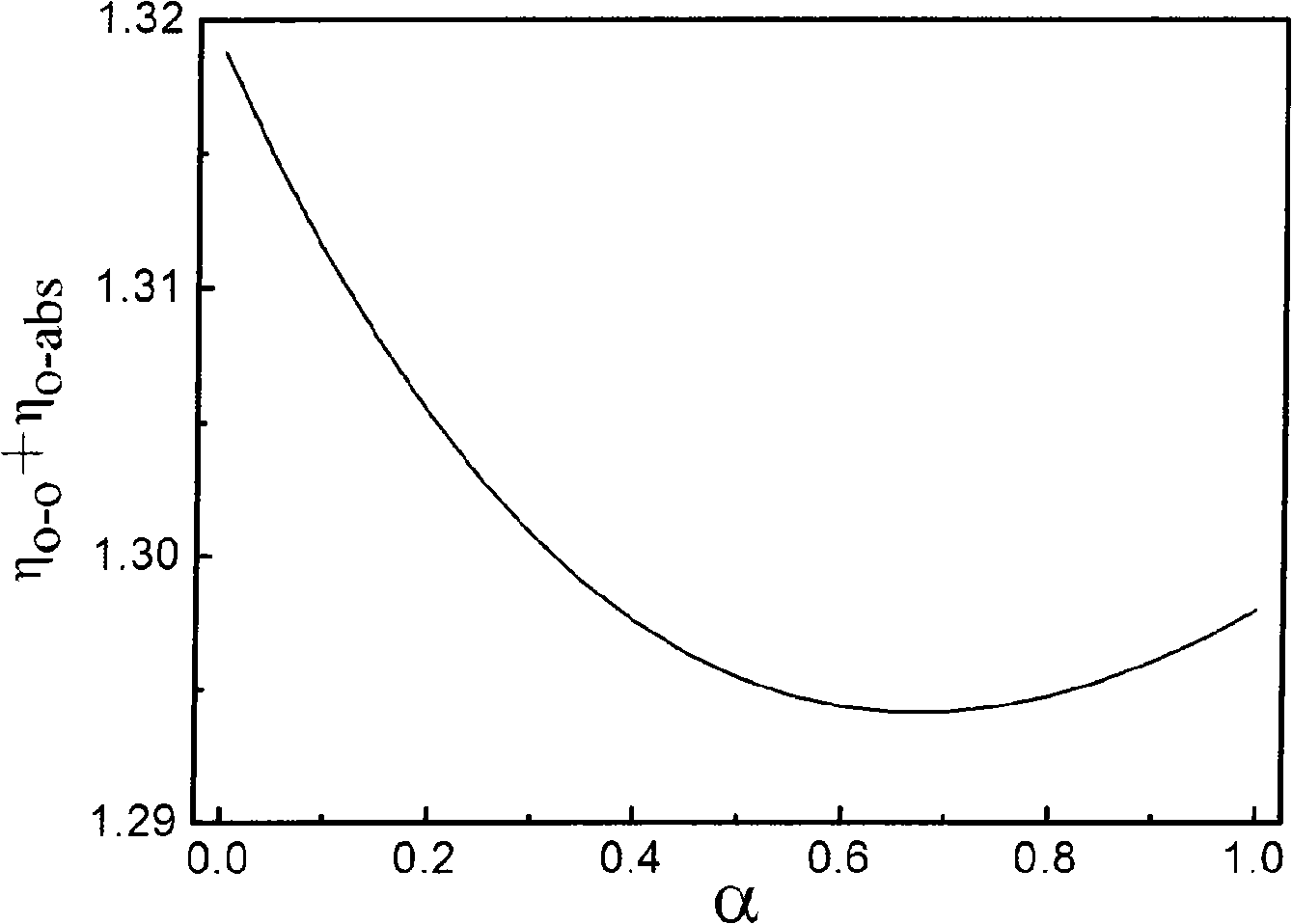

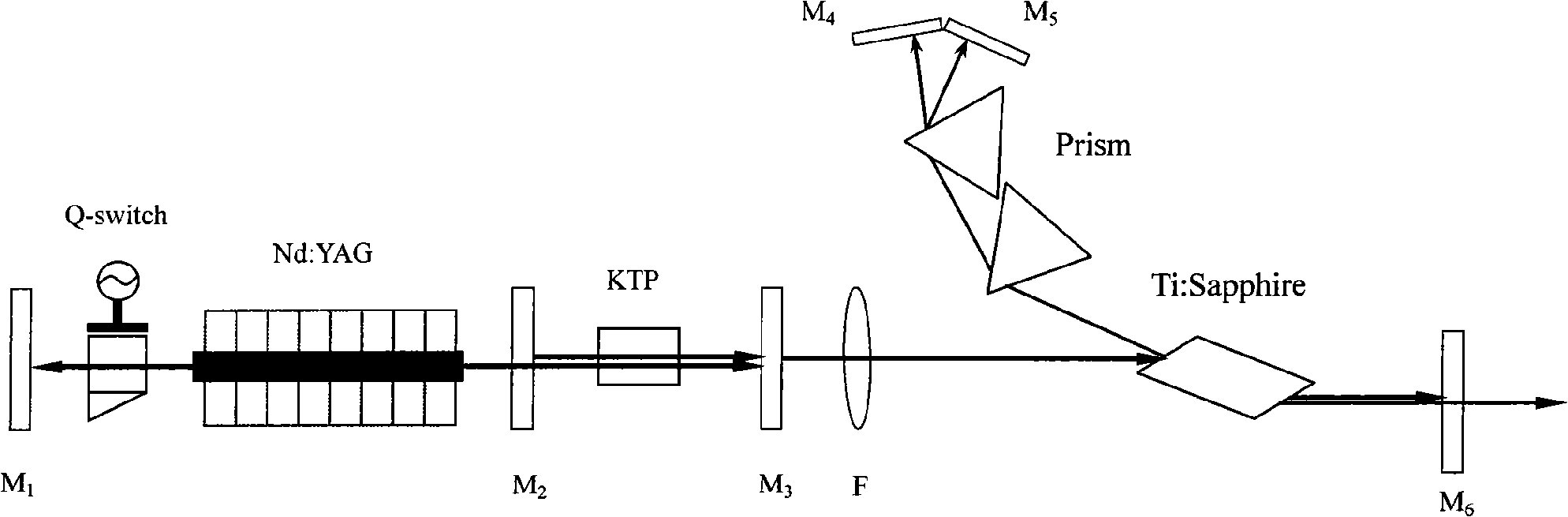

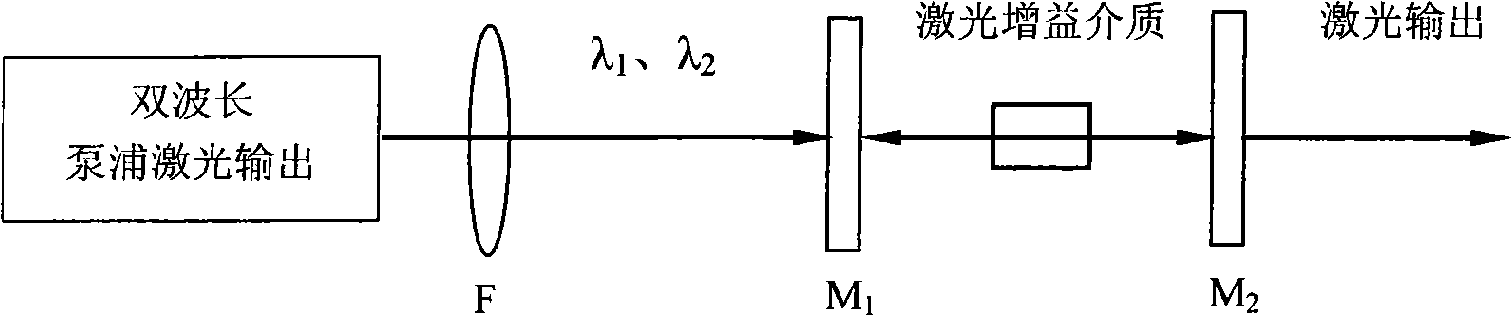

[0017] The present invention combines the advantages of the traditional pumping method with high light-to-light conversion efficiency due to its large absorption coefficient of pump light, and the direct pumping method generates less heat and has high quantum efficiency to form a brand new pumping method - "integrated pumping". Through reasonable calculation and experimental verification, the optimal power ratio relationship of two different pump lights can be determined, so that the problems of high heat generated by traditional pumping and low light-to-light conversion efficiency of direct pumping can be better compensated at the same time, so that The heat generated by the laser and the output power reach an optimal balance point in order to achieve the operation of high power, low heat and high beam quality of the all-solid-state laser. From the point of view of the energy level of the laser gain medium, through reasonable calculation to select the pump light of the two req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com