Straw compression method

A compression method and straw technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the waste of straw resources and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

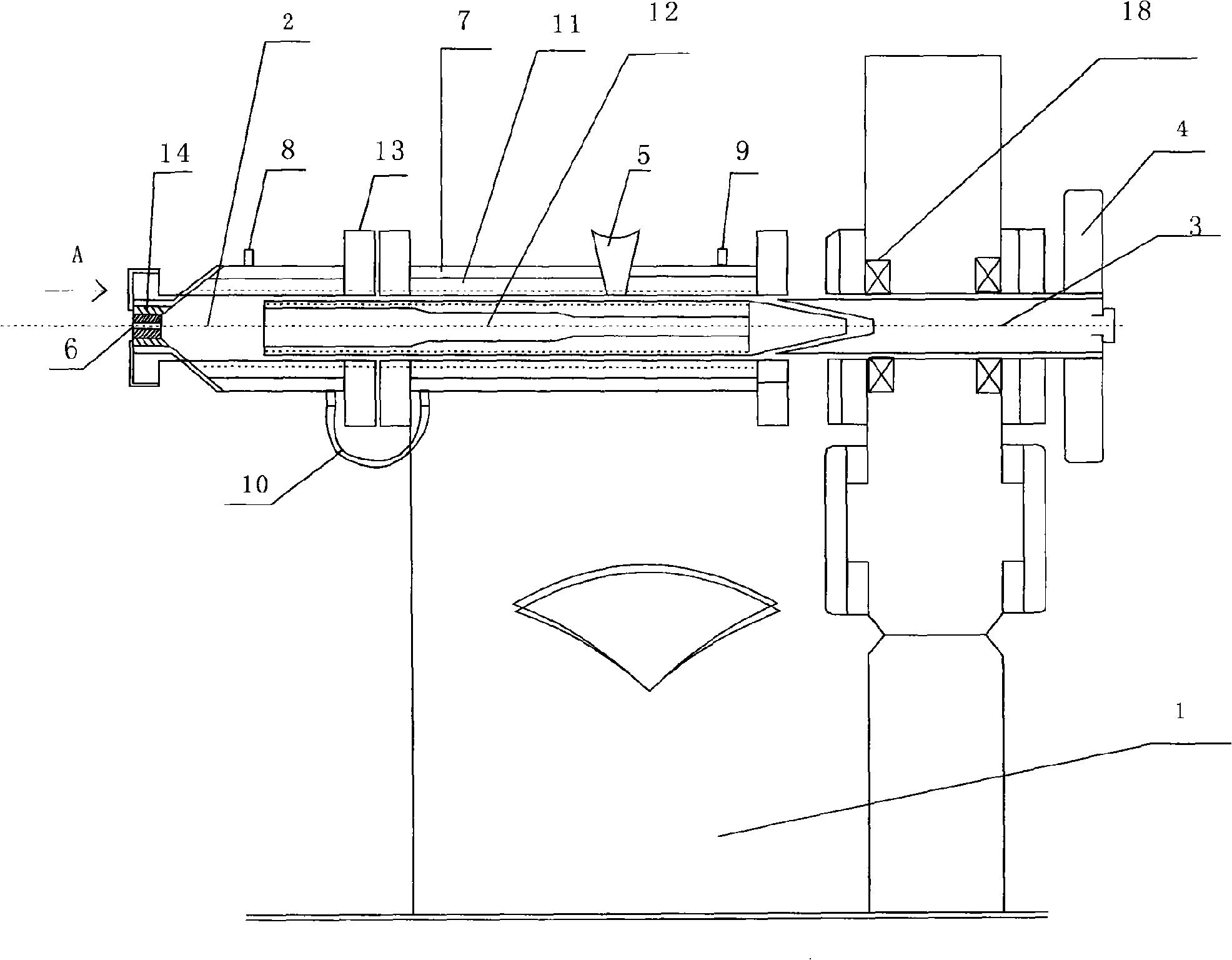

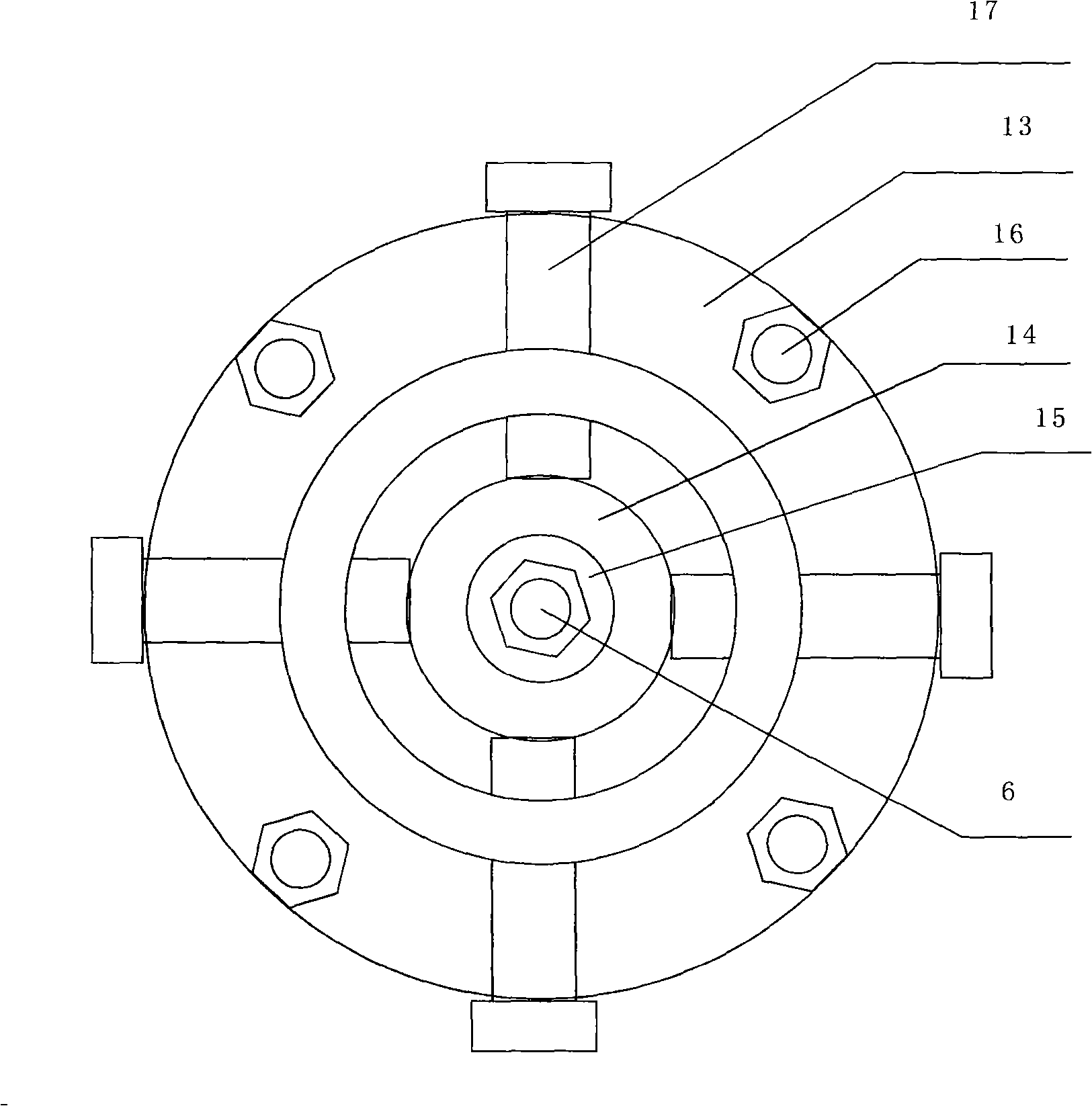

[0022] Such as figure 1 , 2 Shown in the figure: the new straw compression method is to compress the straw into a cylindrical shape through a screw-type propulsion compression device, and the volume is the thickness of the filter tip. Its processing steps are as follows:

[0023] Firstly, the straw is crushed into a powder with a size of less than 6 mm by a crusher, and then 30% of water is added, stirred by a mixer, and the crushed straw is sent from the feed port (5) to a screw-type propulsion compression device for compression, and the compression of the straw The method is that the power unit drives the pulley (4) of the helical propulsion compression device to rotate through the transmission device and the belt drive; the pulley (4) is fixed on one end of the hollow main transmission shaft (3), and the hollow main transmission shaft (3) passes through The bearing (18) is fixed on the upper part of the fuselage (1); the other end of the main transmission shaft (3) is pro...

Embodiment approach 2

[0032] Such as figure 1 , 2 As shown in: This new type of straw compression method can also increase combustion additives: such as coal powder, used as fuel, the processing steps are as follows:

[0033] First, the straw is crushed into powders below 6mm by a crusher, and 20% of combustion additives such as: coal powder are added, and 30% of water is added, stirred by a mixer, and sent to a screw-type propulsion compression device for compression. Two-stage and three-stage spiral propulsion and compression until the softening pool (2) dissolves and shrinks at a high temperature, and the temperature of the softening pool is 120°; finally, it is extruded through the small hole in the center outlet (6) of the alloy film inner sleeve (15) to obtain Cylindrical products with a diameter of 7-12mm, the length can be cut according to the needs, and the length can be cut into 30-50mm for general use.

[0034] The straw compression method is to enter the broken straw from the feed por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com