Block copolymer and process for production of thermally shrinkable film

A block copolymer and heat-shrinkable film technology, which can be used in flat products, applications, household appliances, etc., can solve the problems of difficult-to-heat shrinkable film expansion PET bottle beverages, uneven thickness, etc., and achieve excellent film-making stability and uniform thickness , Excellent shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

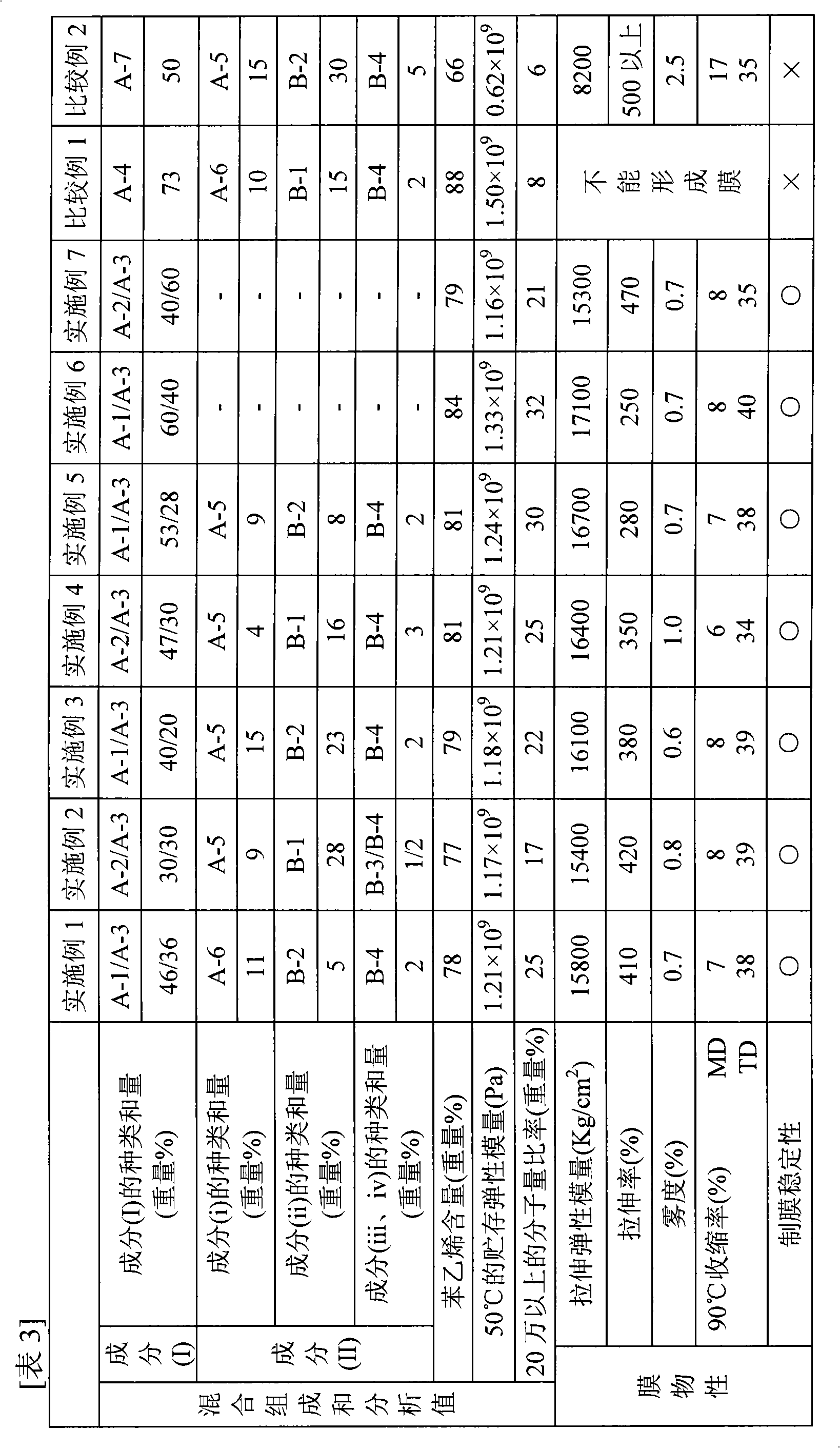

Embodiment 1~7 and comparative example 1、2

[0281] Using the component (I) obtained above, or the composition of the component (I) and the component (II) as a material, heat-shrinkable films are produced by blow molding. Specifically, in Examples 1 to 5, a composition containing component (I) and component (II) was used as the material of the present invention, and in Examples 6 and 7, component (I) was used.

[0282] With respect to 100 parts by weight of ingredient (I) or the composition, add 0.1 parts by weight of erucamide and 0.15 parts by weight of 2-(2'-hydroxy-3'-tert-butyl-5'-methyl-phenyl)- 5-Chlorobenzotriazole.

[0283] On the other hand, in Comparative Examples 1 and 2, block copolymers that do not satisfy the conditions of component (I) of the present invention were used as materials, wherein the styrene content of component (I) was 97% by weight, 58% by weight, ethylene The content of the base aromatic hydrocarbon is 65% by weight to 95% by weight.

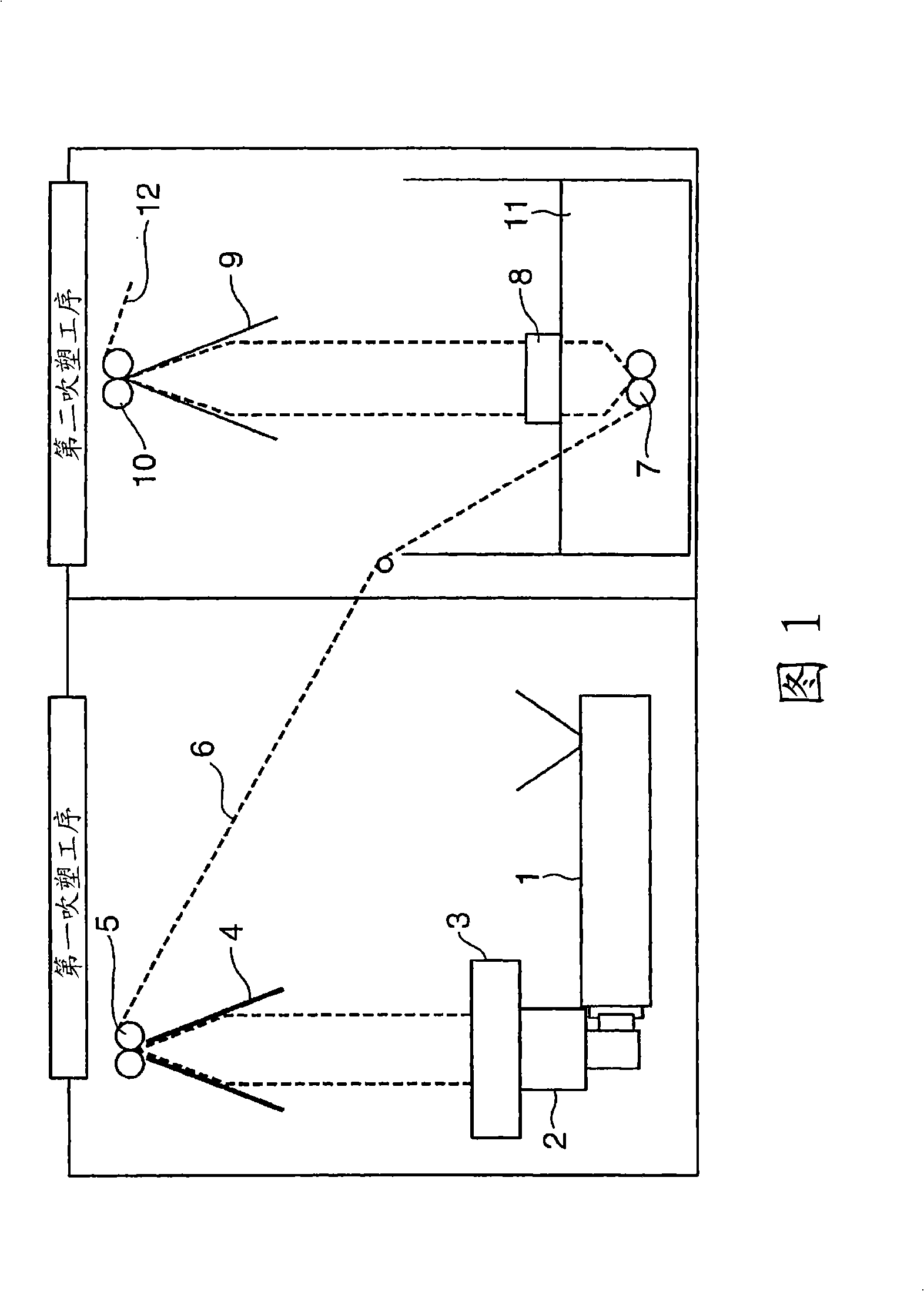

[0284] The production conditions of the heat-shrinkab...

Embodiment 8~12 and comparative example 3、4

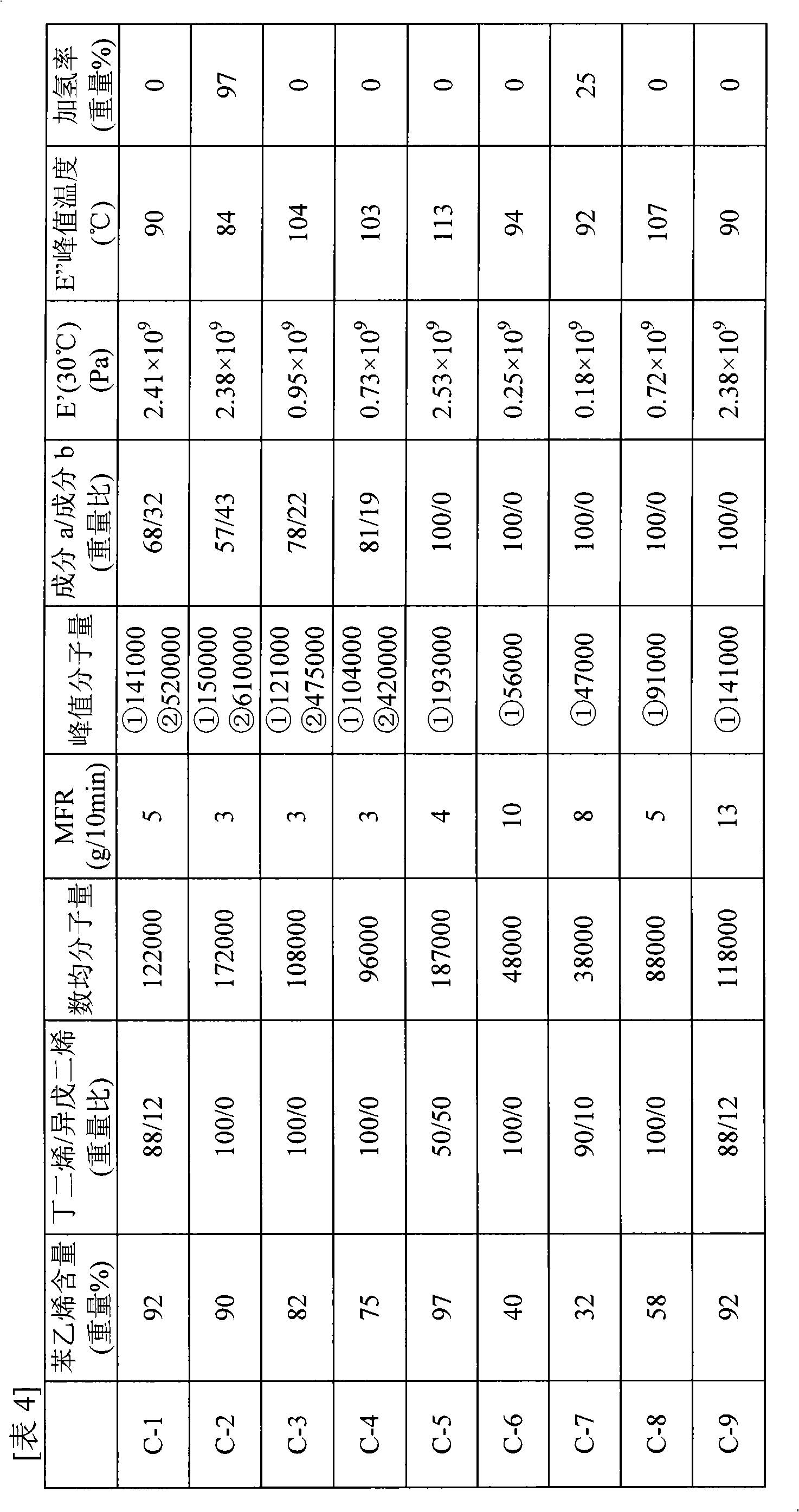

[0289] Next, heat-shrinkable films were produced by blow molding using component (III) shown in Table 6, or a composition of component (III) and component (IV) as a material. Specifically, in Examples 8 to 11, a composition containing component (III) and component (IV) was used as a material, and in Example 12, a component (III) was used as a material.

[0290] With respect to 100 parts by weight of ingredient (III) or the composition, add 0.1 parts by weight of erucamide and 0.15 parts by weight of 2-(2'-hydroxy-3'-tert-butyl-5'-methyl-phenyl)- 5-Chlorobenzotriazole.

[0291] On the other hand, in Comparative Examples 3 and 4, block copolymers that do not satisfy the conditions of component (III) of the present invention were used as materials, wherein the styrene content of component (III) was 97% by weight, 58% by weight, ethylene The content of the base aromatic hydrocarbon is 65% by weight to 95% by weight.

[0292] The manufacturing conditions and manufacturing apparat...

Embodiment 13~15 and comparative example 5

[0295] Based on the mixing formula shown in Table 7, use a 40mm extruder at 200°C to form a sheet with a thickness of 0.25mm, then set the stretching temperature at 87°C, and use a tenter to stretch 5 times on the transverse axis for uniaxial stretching stretched to obtain a heat-shrinkable film with a thickness of about 55 μm.

[0296] Combinations of components (III) and (IV) were used in Examples 13-15. On the other hand, in Comparative Example 5, a block copolymer that does not satisfy the requirements of component (III) of the present invention was used, wherein neither C-8 nor C-9 contained component (b), and component (a) / component (b ) is 10 / 90 to 90 / 10.

[0297] The film properties of the heat-shrinkable film are listed in Table 7. The results show that the performance of the heat-shrinkable film of the present invention is represented by the rigidity of the tensile elastic modulus, the low-temperature shrinkage expressed by the shrinkage rate of 80°C, the natural s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| linear shrinkage | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com