Dry and wet dual-purpose stem pressing glass reinforced plastics biomass pool, producing method and facility thereof

A dry and wet dual-use, fiberglass technology, applied in the field of biogas digesters, can solve the problems of large investment in equipment, achieve the effect of reducing investment, reducing product costs, and improving gas production in winter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

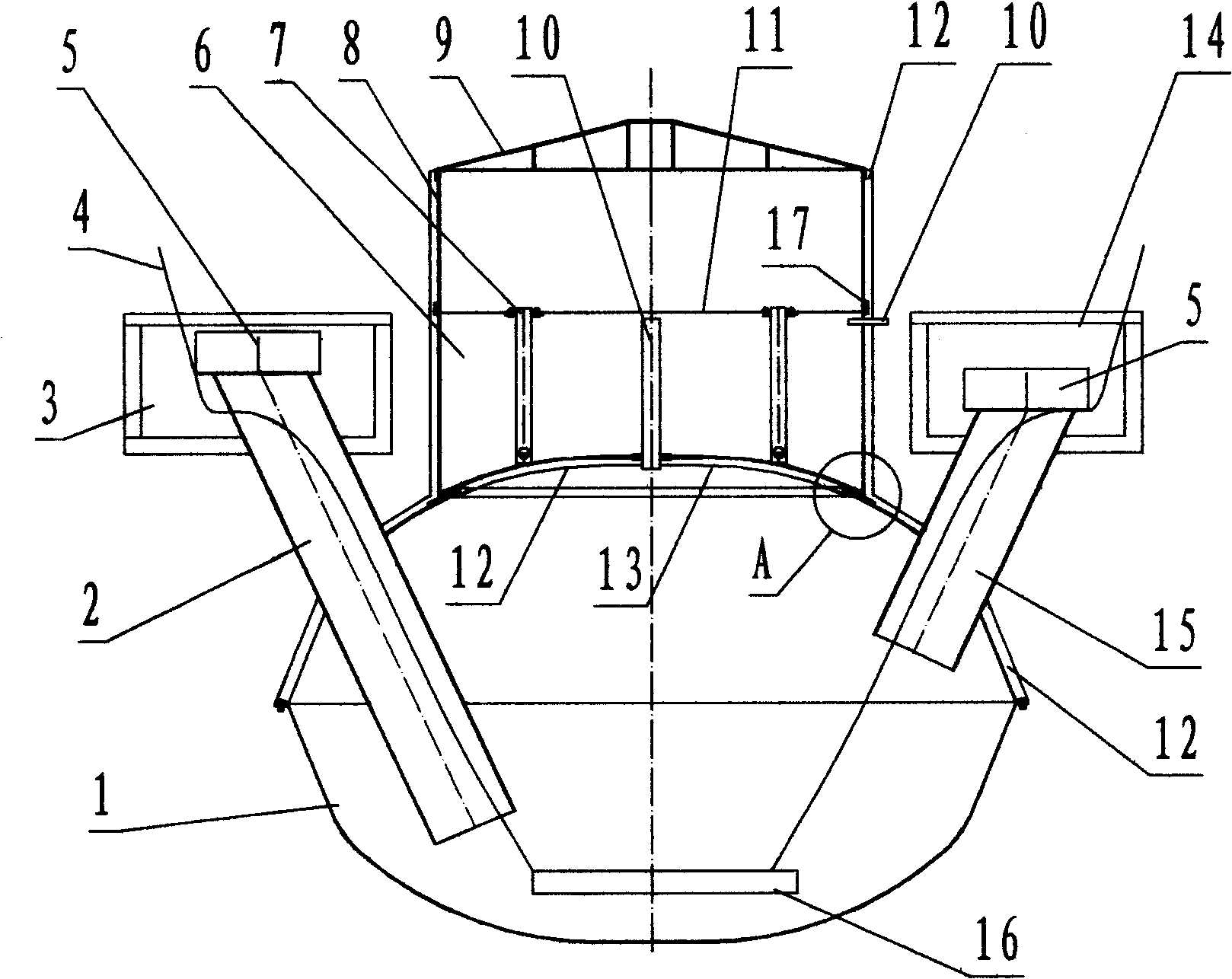

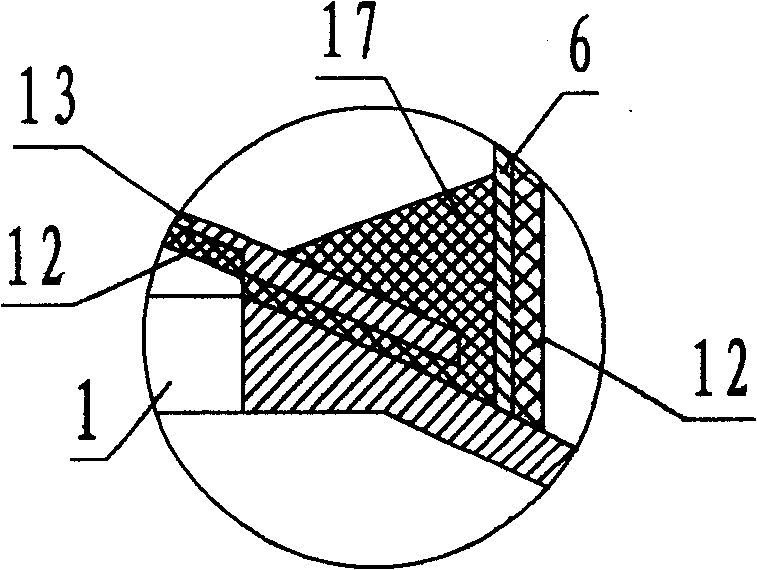

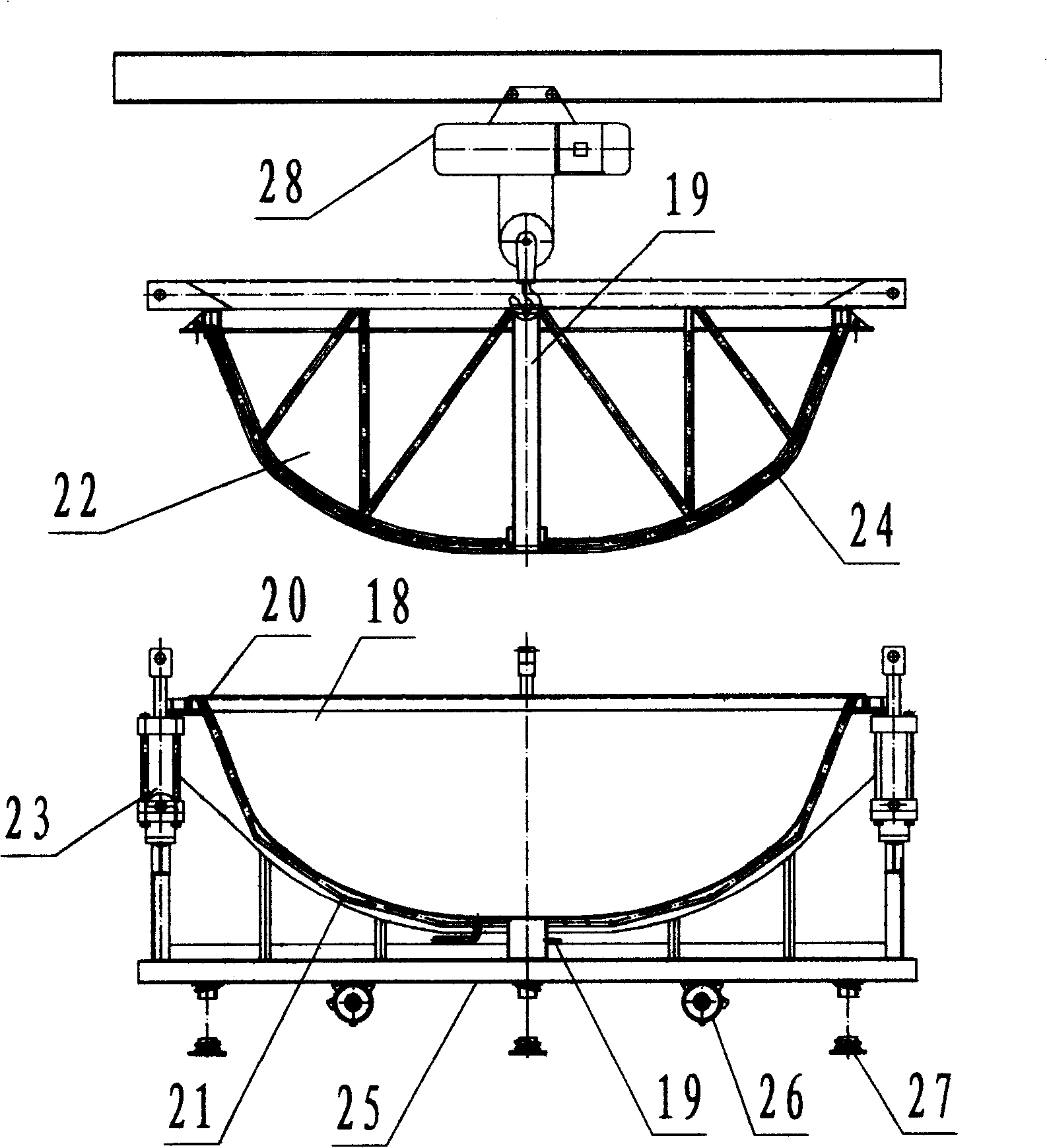

[0013] figure 1 It is a structural diagram of a wet and dry molded FRP biogas digester. A wet and dry molded FRP biogas digester is composed of a fermentation tank (1), a feed room (3), a feed pipe (2), and a discharge room ( 14), discharge pipe (15), gas outlet pipe (10), it is characterized in that: the top of fermenter (1) is provided with the heat preservation cover plate (13) that can open the cover greatly, by gas storage room (6), The live clapboard (11) that 3 upper water pipes (7) are housed, the water pressure room (8), the solar cover (9) are installed on the top of the fermentation tank (1) from bottom to top to become a hydraulic gas storage tank, wherein The water pressure pipe (7) connects the water pressure room (8) with the bottom of the gas storage room (6) and also serves as a support for the living partition (11), and the other air outlet pipe (10) is placed horizontally on the uppermost part of the gas storage room Lead out the biogas, seal the joints bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com