Nano granule water purifying material for removing heavy metal and preparation thereof

A nanoparticle and heavy metal technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as low efficiency, high cost, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

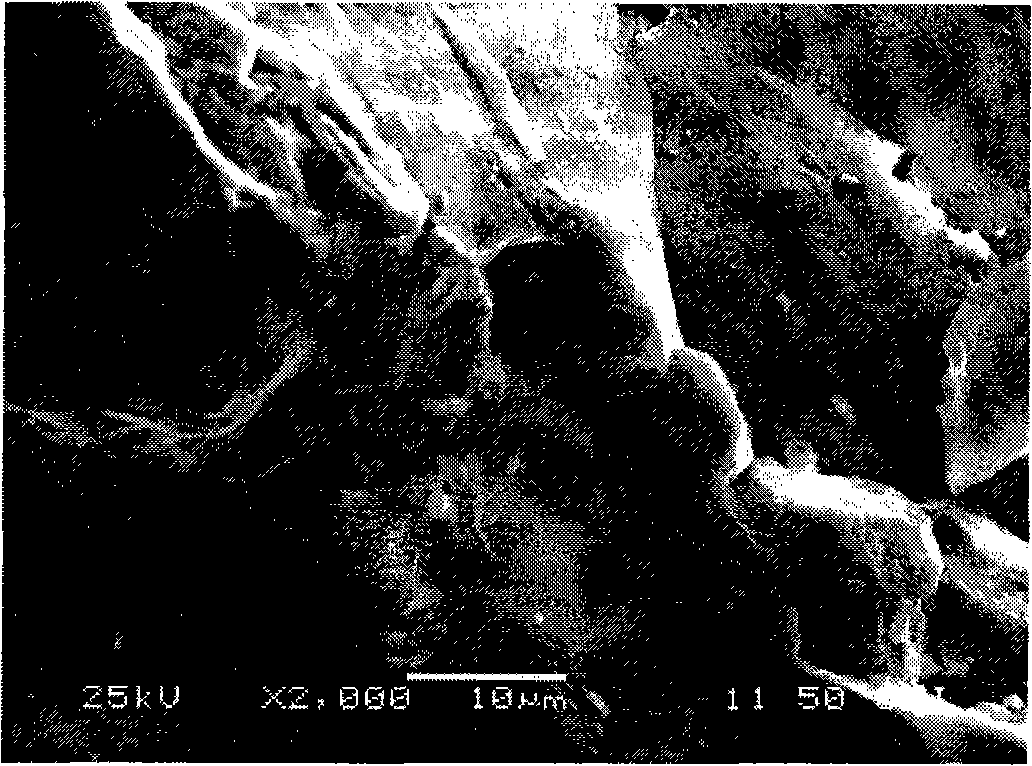

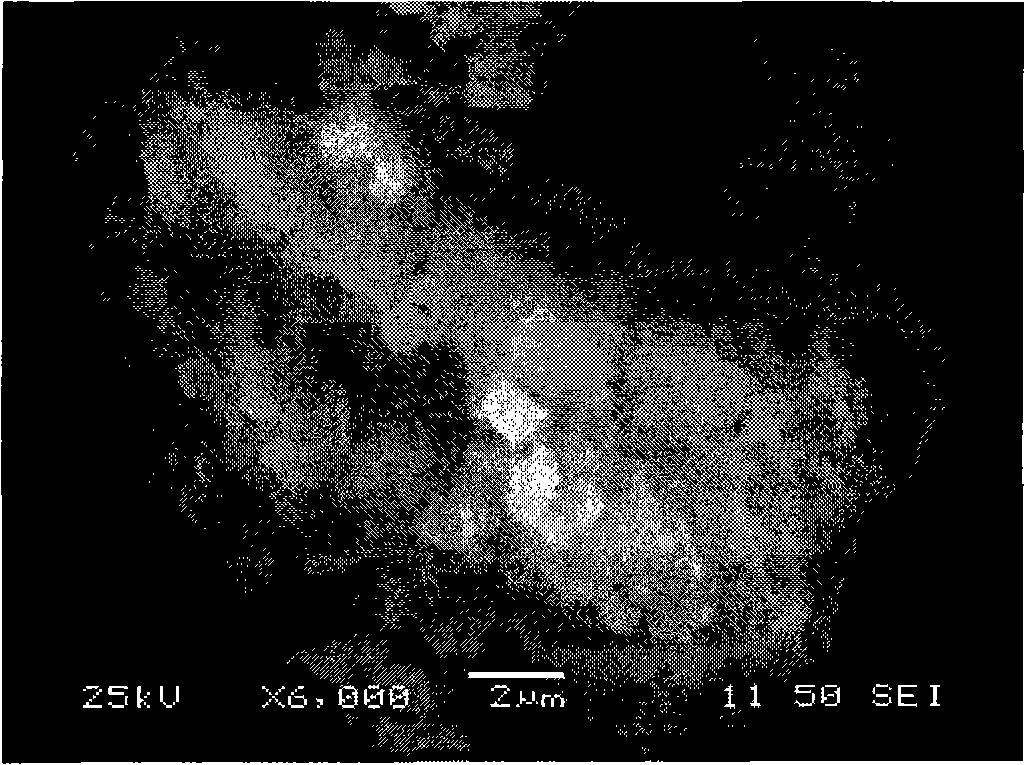

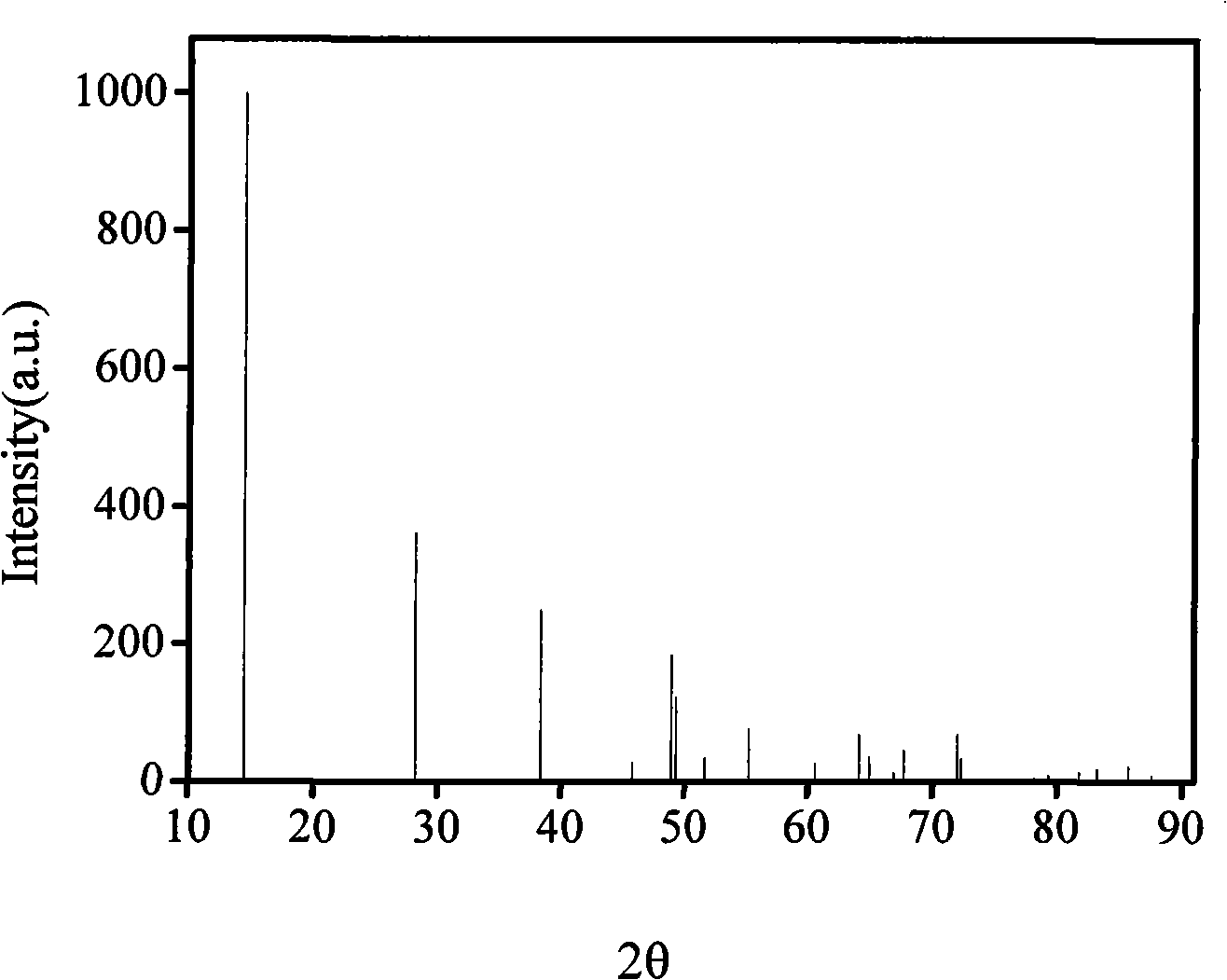

[0117] Take 50g of pretreated quartz sand and sieve it into 16-20 mesh, put it into 200mL secondary deionized water and mix evenly, add 0.5g / L boric acid 10mL, mix evenly for 30min, then add 2.0g Aluminum powder (the average particle size is 75nm, obtained by the electric explosive wire method under the protection of argon), placed in an ultrasonic bath at 80 ° C for 30 min, and then added 2 g / L tetrahexyl orthosilicate to the mixture 10 mL of ethanol solution (the volume ratio of ethanol to tetrahexyl orthosilicate is 5.5:1), continue ultrasonic oscillation for 30 min, and then keep the conditions unchanged for 5 hours, filter the solid-liquid mixture prepared above with a Buchner funnel, and The filter material was dried in a drying oven at a temperature of 70° C. for 10 hours to obtain 50.79 g of the nanoparticle water purification material of the present invention.

[0118] The water purification granular material prepared in this example, by mass, the coating accounts for...

Embodiment 2

[0120] Sieve 50g of pretreated quartz sand into 20-40 mesh, put it into 200mL deionized water and mix evenly, then add 10mL of 0.5g / L sodium salicylate, mix evenly for 30min, then add 2.0g Aluminum powder (the average particle size is 75nm, obtained by the electric explosive wire method under the protection of argon), placed in an ultrasonic tank and ultrasonically oscillated for 30min, and then 10mL of a 2g / L ethanol solution of tetrahexyl orthosilicate was added to the mixture (The volume ratio of ethanol to tetrahexyl orthosilicate is 5.5:1), continue ultrasonic oscillation for 30 minutes, and then keep the conditions unchanged for 5 hours. Filter the solid-liquid mixture prepared above, and dry the filter material in a drying oven at a temperature of 60° C. for 10 hours to obtain 50.79 g of the nanoparticle water purification material of the present invention.

[0121] The water purification granular material prepared in this example, by mass, the coating accounts for 1.56...

Embodiment 3

[0123] Put 50g of pretreated quartz sand of 40-60 mesh into 200mL of deionized water and mix evenly, then add 0.5g / L sodium salicylate 10mL, after mixing evenly for 30min, add 4.0g of aluminum powder ( The average particle size is 75nm, which is obtained under the protection of argon by the electric explosive wire method), placed in an ultrasonic tank for ultrasonic oscillation for 30min, and then 10mL of an ethanol solution of 2g / L tetrahexyl orthosilicate is added to the mixture (ethanol and The volume ratio of tetrahexyl orthosilicate is 2.0:1), continue ultrasonic oscillation for 30 minutes, and then keep the conditions unchanged for 5 hours. Filter the solid-liquid mixture prepared above, and dry the filter material in a drying oven at a temperature of 60° C. for 10 hours to obtain 51.00 g of the nanoparticle water purification material of the present invention.

[0124] The water purification granular material prepared in this example, by mass, the coating accounts for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com