Ball shaped 3,3'-dichloro-4,4'-diaminodiphenylmethane (MOCA), preparation and equipment

A technology of diaminodiphenylmethane and diaminodiphenyl, which is applied in the field of preparation of organic compound dosage forms, can solve problems such as the advent of dosage forms, and achieve the effects of reducing labor intensity and workload, simple design structure, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

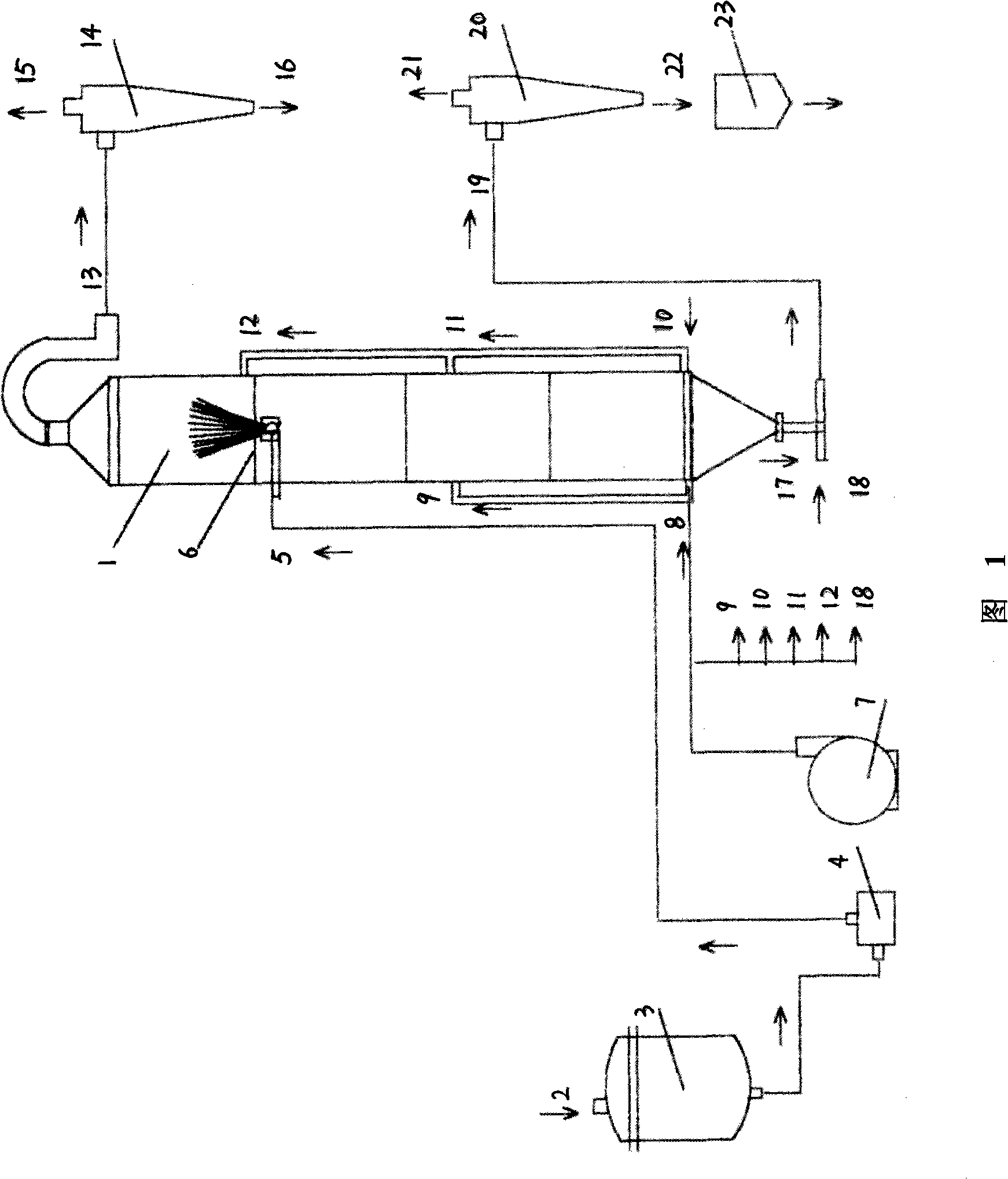

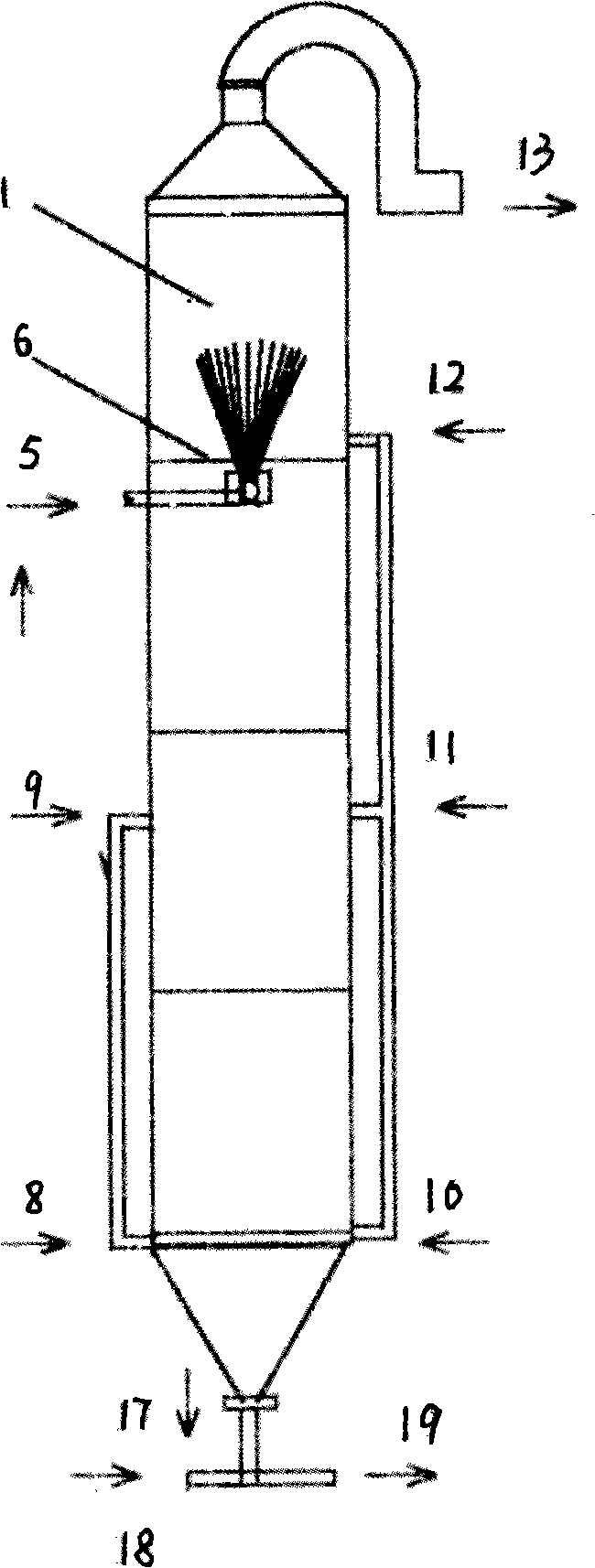

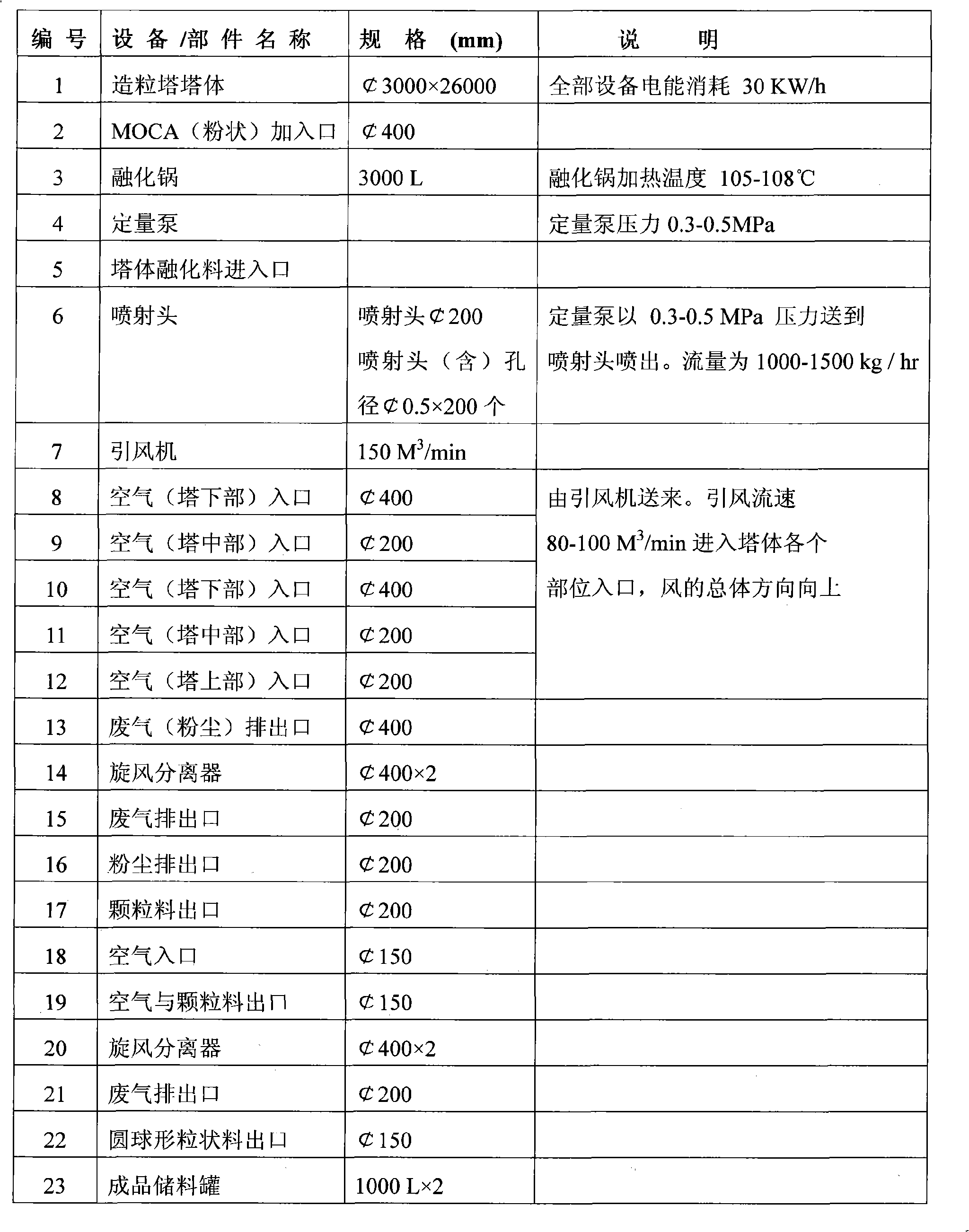

[0020] The process operation is as follows: in the 3000L melting pot 3, add powdered MOCA from 2, heat it to 105-108°C to melt it, and use the quantitative pump 4 to pass through the tower at a pressure of 0.3-0.5 MPa. The solid melt material inlet 5 enters the spray head 6 and sprays upwards. Under the action of gravity, the sprayed fine liquid flow immediately descends and is entered by the air inlets 8, 9, 10, 11, and 12 of the free tower body 1. Under the action of the spiral air flow from bottom to top, the thin liquid flow is stripped into fine droplets and continues to descend. Based on the fact that the tower body 1 itself is an environment with different temperature gradients, the usual situation is that from the initial normal temperature state of operation, the temperature is gradually raised to 90-95°C in the upper part of the tower body, 80-85°C in the middle part, and 80-85°C in the lower part. 40-45°C. The fine droplets formed above will be cooled into regular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com