Device for wet phosphoric acid refining and high-purity ammonium molybdate preparation

A wet-process phosphoric acid, ammonium molybdate technology, applied in molybdenum compounds, phosphorus compounds, chemical instruments and methods, etc., can solve the problems of high equipment investment and depreciation costs, unstable quality of purified products, and difficulty in meeting tolerance at the same time. , to achieve the effect of convenient operation, reduce the number of processing and floor space, avoid volatilization and decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

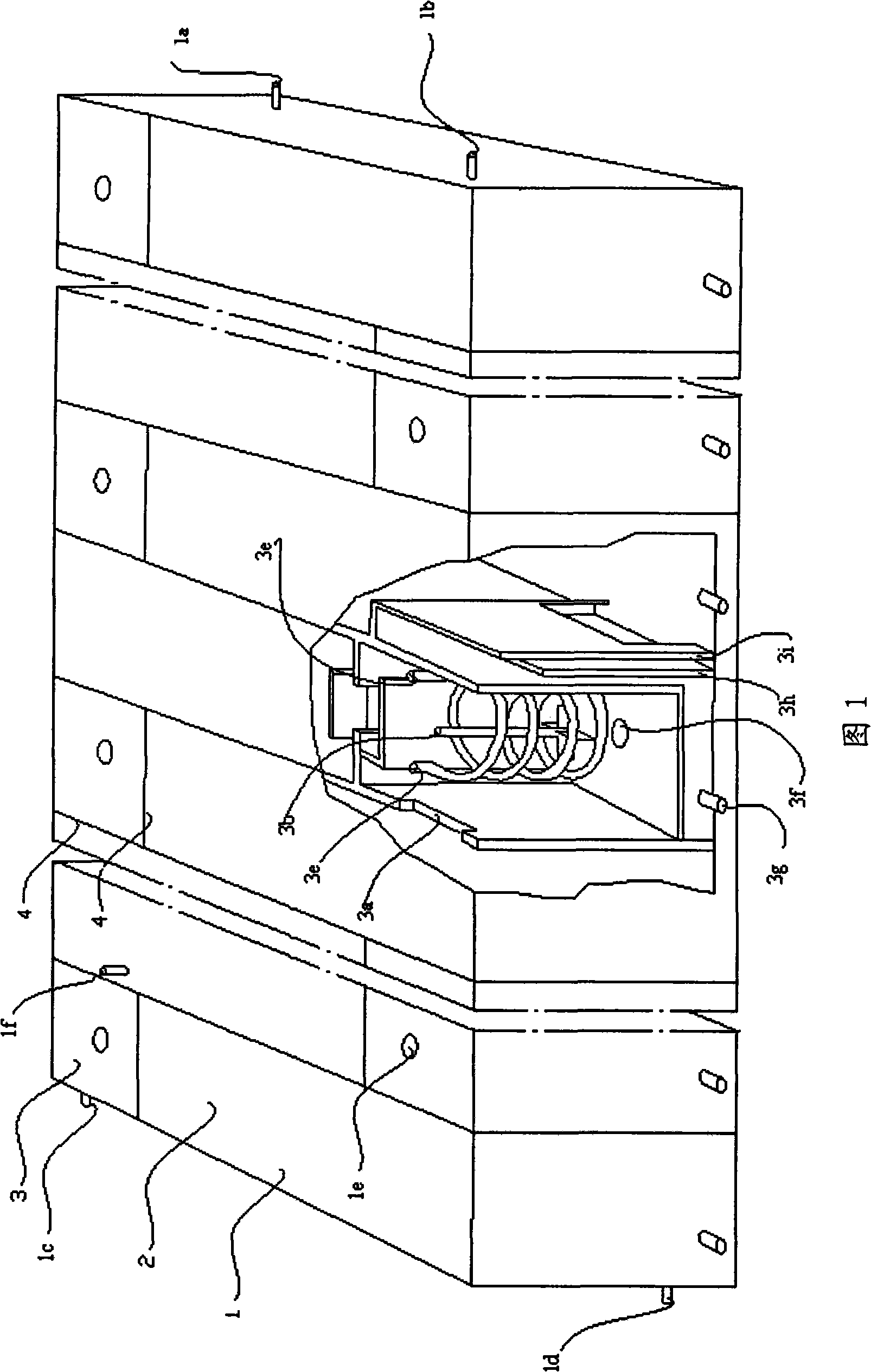

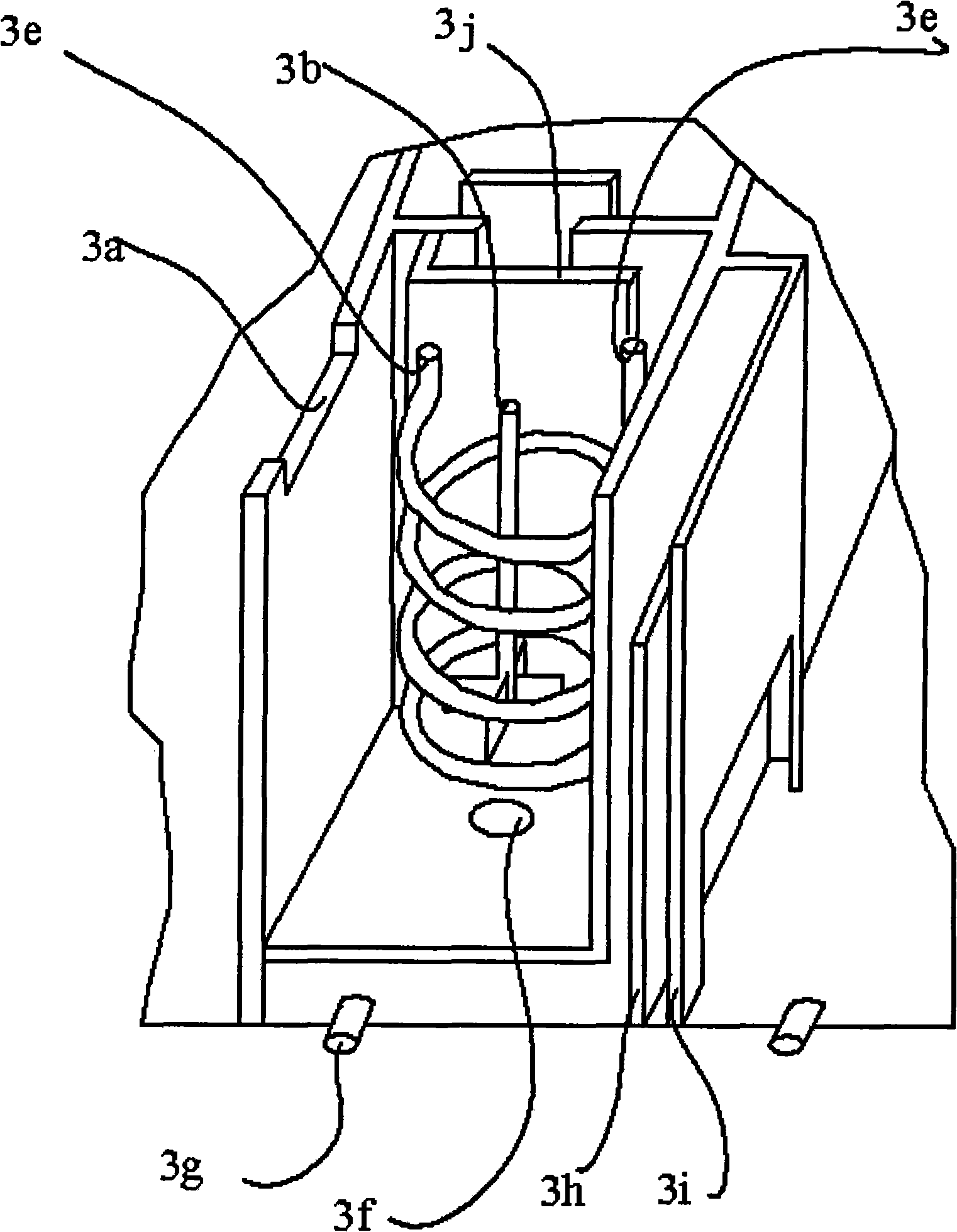

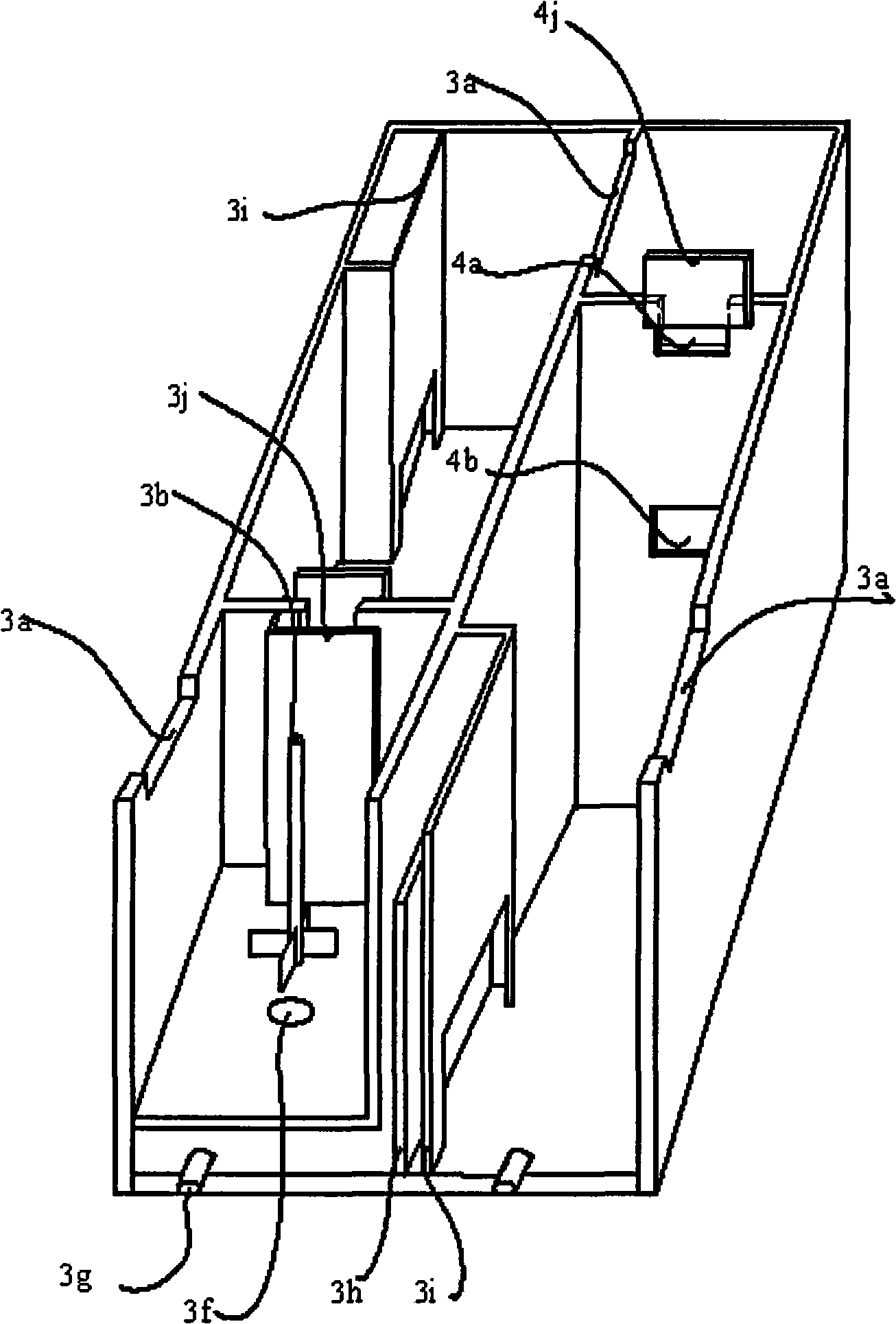

[0055] By Fig. 1, 2, 3, the present invention is used for wet-process phosphoric acid refining and prepares the device of high-purity ammonium molybdate, comprises: extraction tank 1, washing tank and stripping tank;

[0056] The raw materials of the extraction tank 1, the washing tank and the stripping tank are made of I-shaped steel as the skeleton, and the o-phthalic resin is used as the matrix, and the surface is covered with polypropylene;

[0057] The interior of the extraction tank 1 is divided into seven rectangular sub-tanks with a partition 4 of the same material as the tank body. Each sub-tank includes a clarification chamber 2 and a mixing chamber 3. The upper part of the clarification chamber 2 and the mixing chamber 3 The organic phase reflux groove 4a is separated from the partition plate with the mixed phase outlet hole 4b in the middle, and the mixing chamber between the upper and lower sub-troughs is adjacent to the clarification chamber;

[0058]The extracti...

Embodiment 2

[0090] The tank bodies of the extraction tank 1, the washing and stripping tank 5 and the extraction and stripping tank 6 are made of I-shaped steel as the skeleton, with m-benzene resin as the matrix, and the surface is covered with novolac epoxy vinyl ester resin. The internal partitions 4 of the tank, the heavy phase weirs 3i, 3h, and the L-shaped baffles 3j are made of m-benzene resin as the matrix, and the surface is covered with novolac epoxy vinyl ester resin.

Embodiment 3

[0092] The tank bodies of the extraction tank 1, the washing and stripping tank 5 and the extracting and stripping tank 6 are made of channel steel as the skeleton, tetrabromo or tetrahydrophthalic anhydride resin as the matrix, and the surface is covered with novolac epoxy vinyl ester resin. The inner part of the tank The inner part of the tank 4, the heavy phase weir plate 3i, 3h, and the L-shaped baffle 3j are based on tetrabromo or tetrahydrophthalic anhydride resin, and the surface is covered with novolac epoxy vinyl ester resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com