Sewage treating device and process

A sewage treatment device and packaging technology, applied in the field of water treatment, can solve the problems of low energy consumption per ton of water, high aeration rate, and restrictions on popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

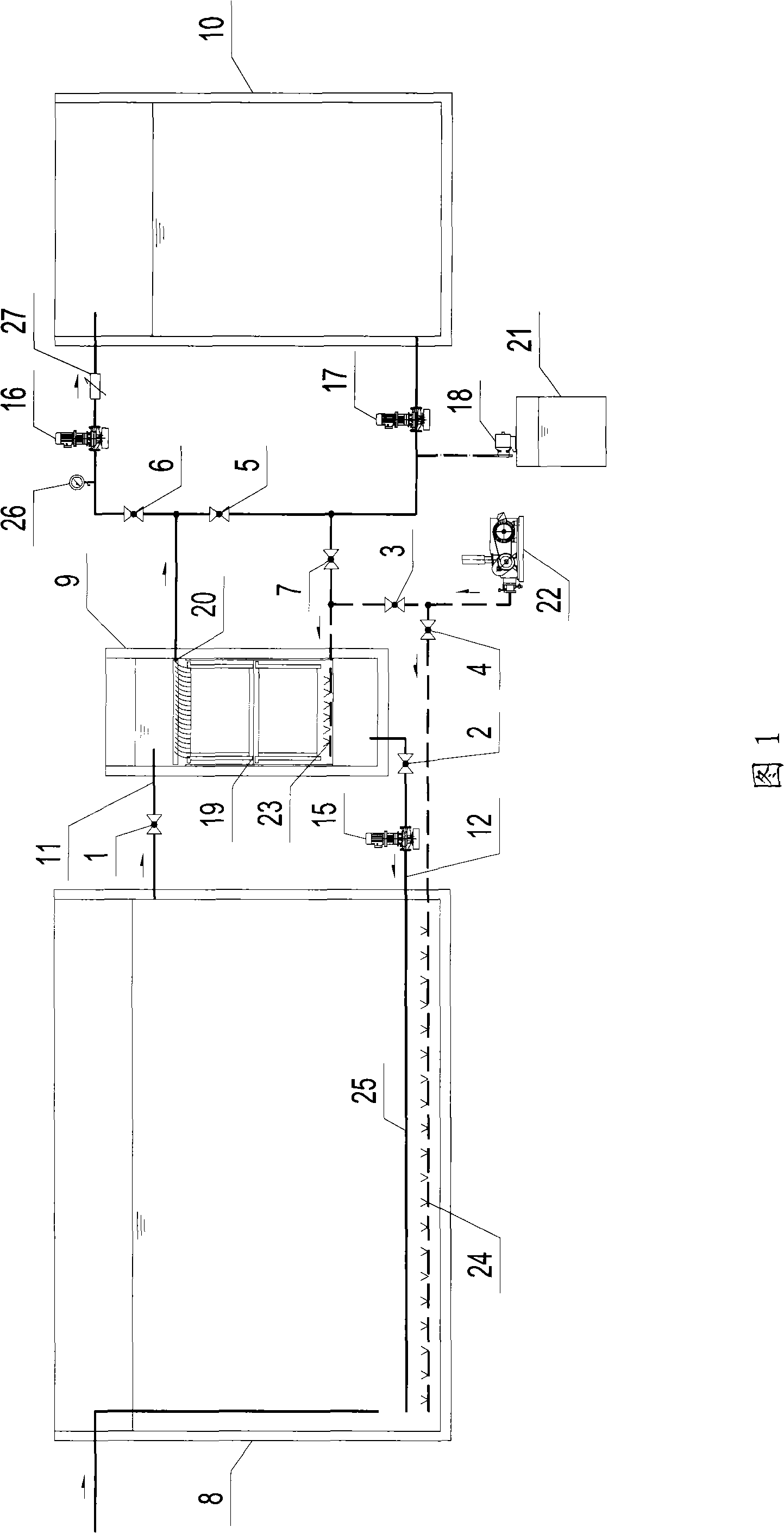

Embodiment 1

[0073]As shown in Fig. 1 and Fig. 4, a kind of sewage treatment device comprises bioreactor 8, and the membrane filter tank 9 that is independent with biological reactor 8 and co-wall setting, the membrane separation equipment 19 that is installed in the membrane filter tank, The produced water storage tank 10 used to store the permeate of the membrane separation equipment, the activated sludge mixture in the biological reaction tank 8 is transported to the feed liquid supply pipe 11 in the membrane filter tank 9 and the feed liquid supply valve installed on it 1. The position where the feed liquid supply pipe 11 passes through the side wall of the biological reaction tank 8 is located at the top of the side wall but the top of the pipe is 400 mm (mm) lower than the inner water surface, and the position where it passes through the side wall of the membrane filter tank 9 is located at the top of the side wall. The upper part of the side wall but the top of the pipe is 200mm lowe...

Embodiment 2

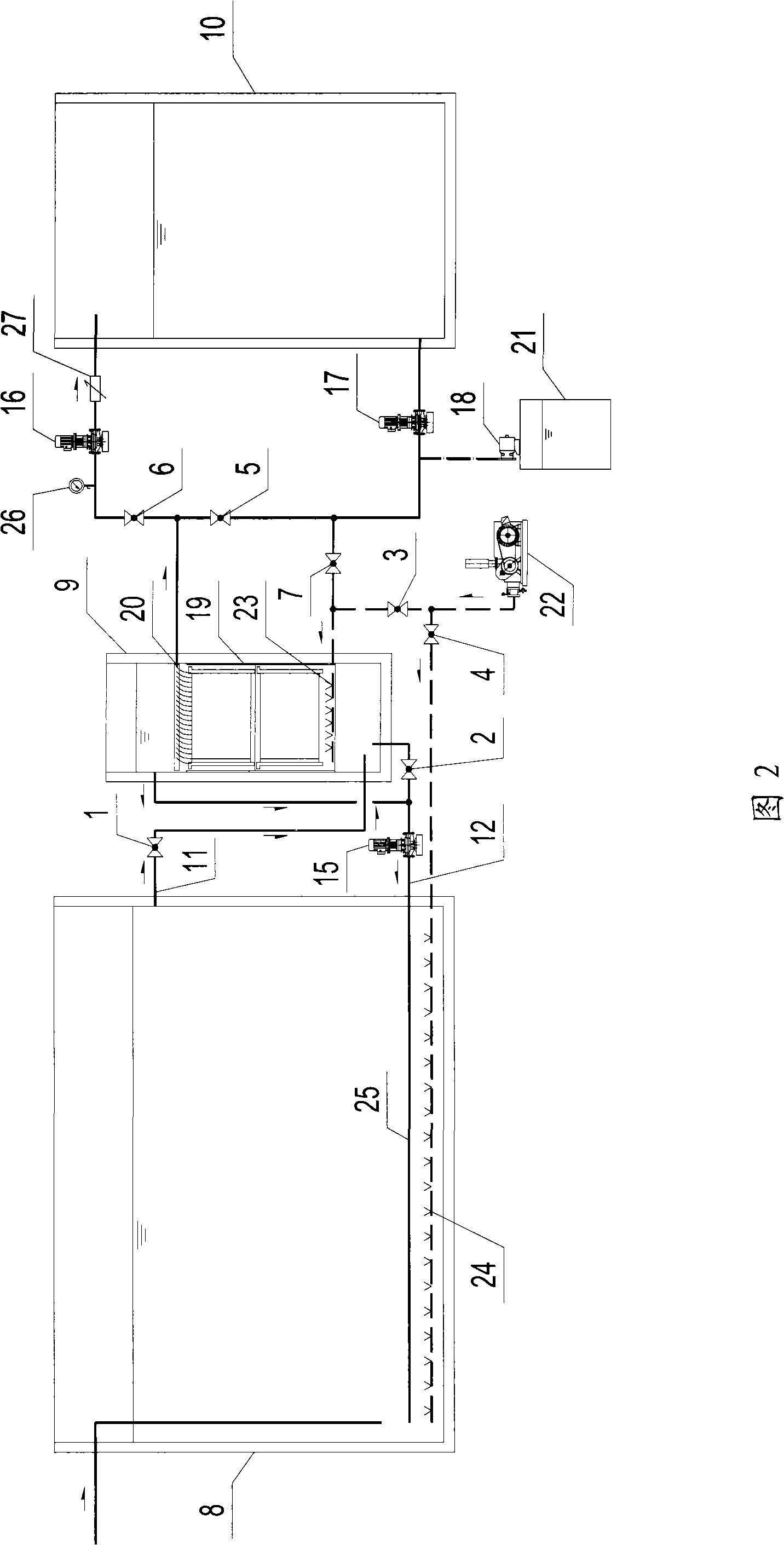

[0085] As shown in Fig. 2 and Fig. 5, a kind of sewage treatment device, most of structure is identical with embodiment 1, the difference is, the activated sludge mixture in the biological reaction tank 8 is transported to the material in the membrane filter tank 9 The position where the liquid supply pipe 11 passes through the side wall of the biological reaction tank 8 is located at the top of its side wall but the top of the pipe is 400mm lower than its inner water surface, and the position where it passes through the side wall of the membrane filter tank 9 is located at the bottom of its side wall but the tube The bottom is 100mm higher than the bottom of the pool, and is positioned below the membrane separation device 19. The feed liquid return pipe 12 that transports the concentrated solution in the membrane filter 9 back to the bioreactor 8 is divided into two branches, one of which passes through the The position of the side wall of the membrane filter tank 9 is located...

Embodiment 3

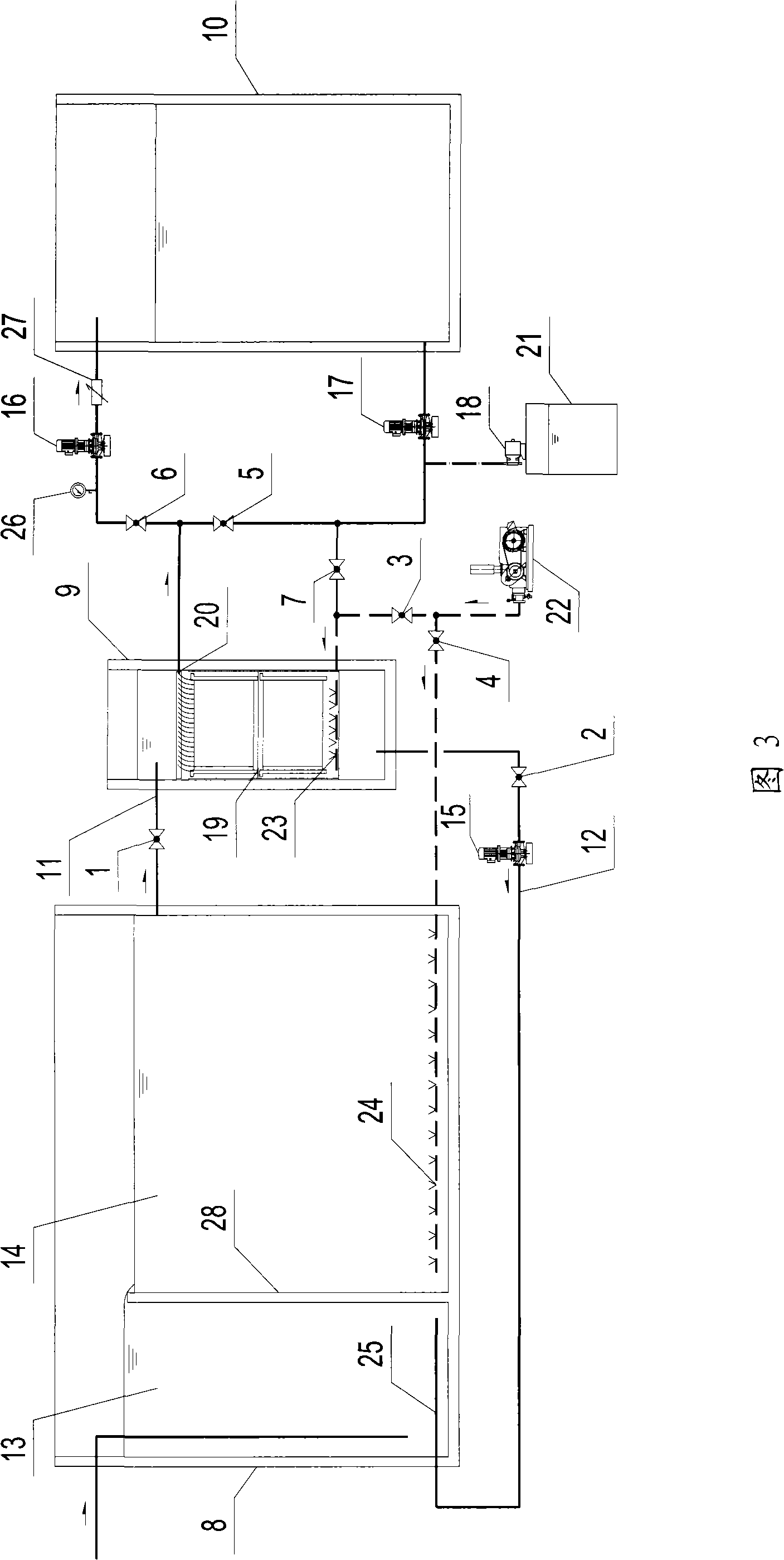

[0092] As shown in Fig. 3 and Fig. 6, a kind of sewage treatment device, most of structure is identical with embodiment 1, difference is, be provided with partition wall 28 in the bioreaction tank 8, partition wall 28 divides bioreaction tank 8 into Only the two parts separated from each other communicated by the top of the partition wall 28, i.e. the anoxic zone 13 and the aerobic zone 14, the volume ratio of the two is 1:3, the bottom of the partition wall 28 is connected with the bottom plate of the biological reaction tank 8 As a whole, there are no holes on the wall, and the top is 200mm away from the water surface. The water distribution device 25 installed at the bottom of the biological reaction tank 8 is only located in the anoxic zone 13, and the 24 gas distribution devices installed in the biological reaction tank 8 are located at the bottom of the biological reaction tank 8. In the aerobic zone 14, the membrane separation equipment 19 and the blower 22 are the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com