Preparation for single wall carbon nano-tube monomer-containing compound for PBO polymerization

A technology of single-walled carbon nanotubes and composites, applied in chemical instruments and methods, liquid crystal materials, etc., can solve the problem that nanotube bundles cannot fully exert the reinforcing effect of SWNT on PBO matrix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

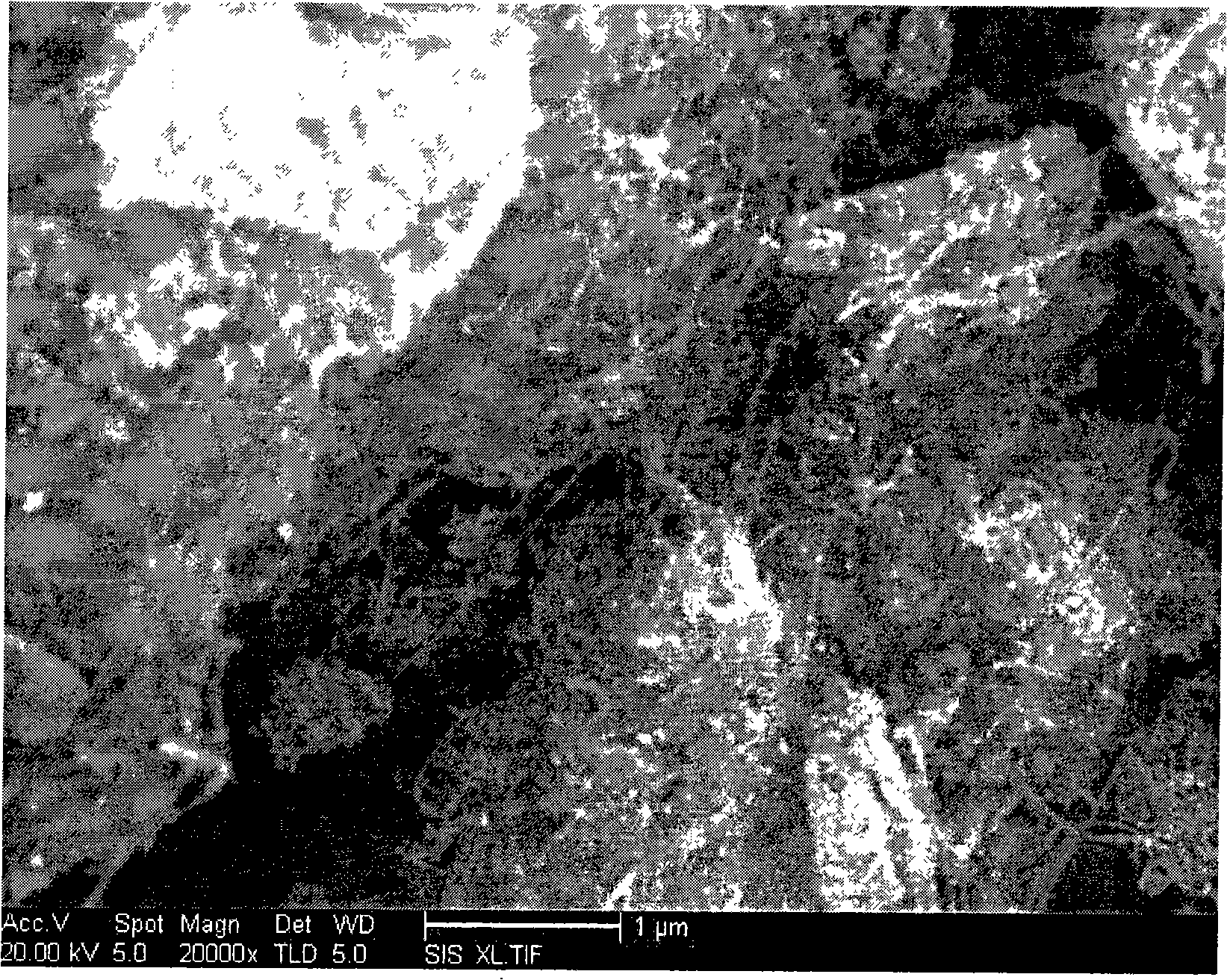

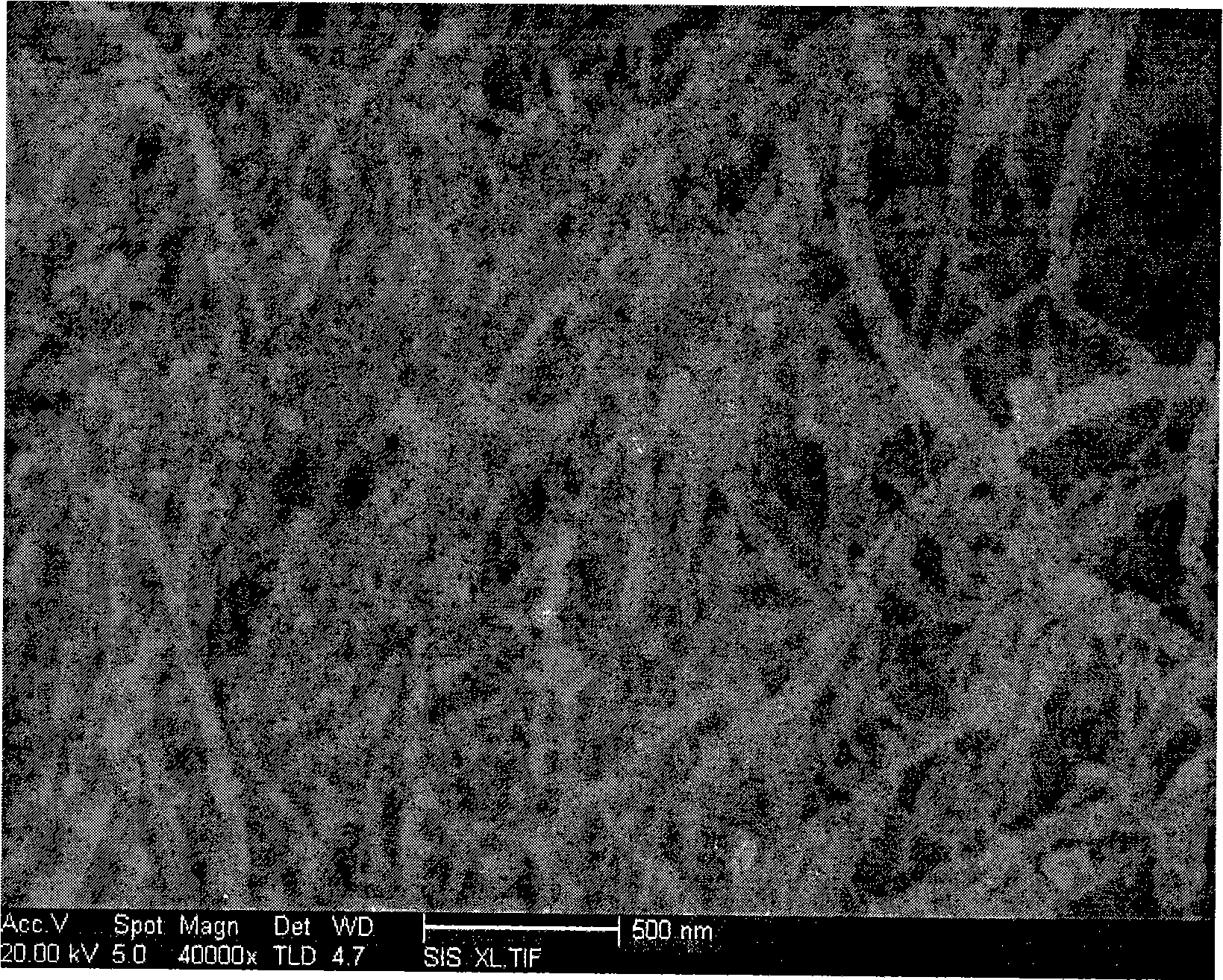

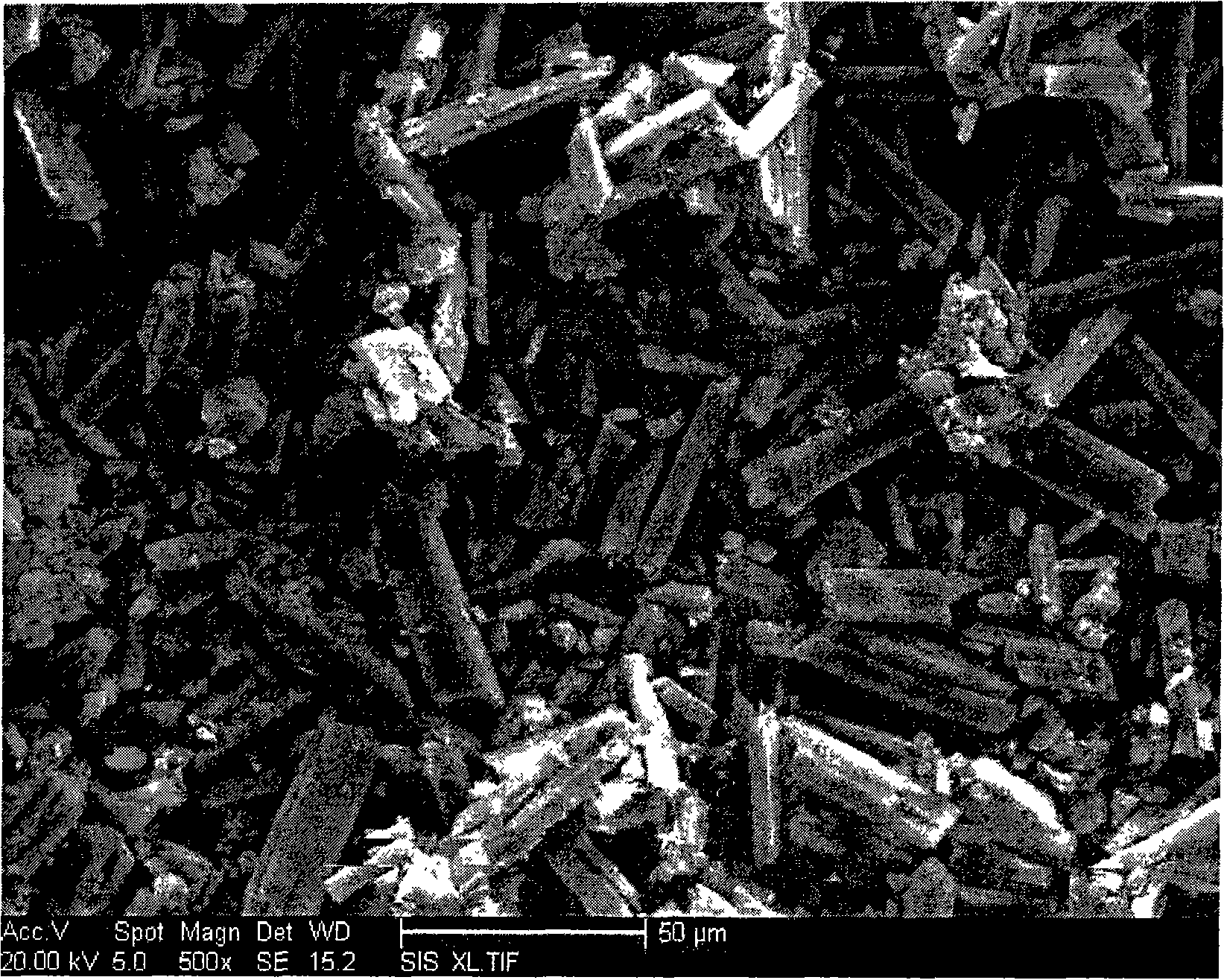

Image

Examples

specific Embodiment approach 1

[0011] Embodiment 1: The preparation method of the single-walled carbon nanotube monomer complex used for PBO polymerization in this embodiment is as follows: 1. Terephthalic acid and NaOH are mixed according to the molar ratio of 1:2 to prepare terephthalic acid Sodium diformate aqueous solution, wherein the concentration of NaOH aqueous solution is 0.5 ~ 3mol / L; 2. The single-walled carbon nanotube aqueous solution, the carboxylated single-walled carbon nanotube aqueous solution and the single-walled carbon nanotube treated with oleum, cut short and carboxylated The aqueous solution of carbon nanotubes is added to the aqueous solution of sodium terephthalate obtained in step 1 to obtain a mixed solution, and then the mixed solution is heated to 40°C to 60°C, wherein the volume of the aqueous solution of single-walled carbon nanotubes and the aqueous solution of sodium terephthalate obtained in step 1 The ratio is 1:1~2, the volume ratio of the aqueous solution of carboxylated...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of the NaOH aqueous solution in Step 1 is 0.6-1.5 mol / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment differs from Embodiment 1 in that the concentration of the NaOH aqueous solution in Step 1 is 1.6-2.9 mol / L. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com